Polyelectrolyte and graphene composite resistive moisture sensor and manufacturing method thereof

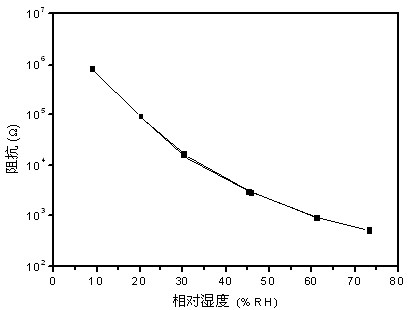

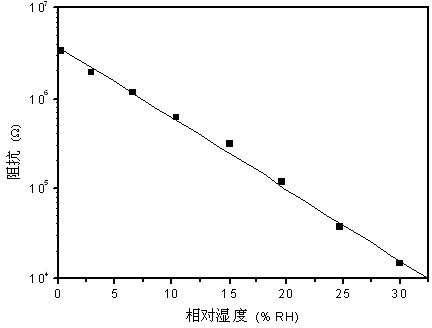

A graphene composite and polyelectrolyte technology, which is applied in the direction of material resistance, can solve problems such as limited application, high resistance, and difficulty in measurement, and achieve good linear response, high conductivity, and reduced resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

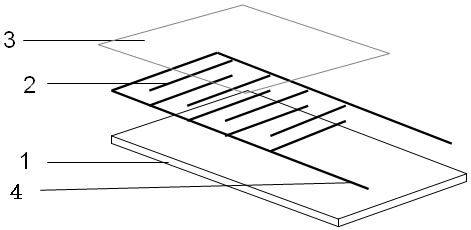

[0024] 1) Clean the surface photolithography and evaporate the ceramic substrate with interdigitated gold electrodes, and dry it for later use;

[0025] 2) Dilute 5 g of 25%wt PDDA solution with 5 ml of deionized water;

[0026] 3) Add 5 mg of graphene oxide to 5 ml of water, ultrasonically oscillate for 15 minutes, then add dropwise to the PDDA solution prepared in step 2), continue ultrasonically oscillating for 15 minutes, then add 0.1 ml of 85% Hydrazine hydrate, heated at 65°C for 5 hours to obtain a precursor solution;

[0027] 4) Immerse the ceramic interdigitated gold electrode in step 1) in the precursor solution prepared in step 3) for 0.5 minutes, pull it out, and heat it at 60°C for 1 hour to obtain a composite moisture-sensitive electrode covered with polyelectrolyte and graphene. Thin film resistive humidity sensor.

Embodiment 2

[0029] 1) Clean the surface photolithography and evaporate the ceramic substrate with interdigitated gold electrodes, and dry it for later use;

[0030] 2) Dilute 3 g of 25%wt PDDA solution with 7 ml of deionized water;

[0031] 3) Add 7 mg of graphene oxide to 7 ml of water, ultrasonically oscillate for 20 minutes, then add dropwise to the PDDA solution prepared in step 2), continue ultrasonically oscillating for 20 minutes, then add 0.2 ml of 85% Hydrazine hydrate, heated at 125°C for 7 hours to obtain a precursor solution;

[0032] 4) Immerse the ceramic interdigitated gold electrode in step 1) in the precursor solution prepared in step 3) for 0.8 minutes, pull it out, and heat it at 70°C for 2 hours to obtain a composite moisture-sensitive electrode covered with polyelectrolyte and graphene. Thin film resistive humidity sensor.

Embodiment 3

[0034] 1) Clean the surface photolithography and evaporate the ceramic substrate with interdigitated gold electrodes, and dry it for later use;

[0035] 2) Dilute 1 g of 25%wt PDDA solution with 10 ml of deionized water;

[0036] 3) Add 15 mg of graphene oxide to 10 ml of water, ultrasonically oscillate for 30 minutes, then add dropwise to the PDDA solution prepared in step 2), continue ultrasonically oscillating for 30 minutes, then add 0.4 ml of 85% Hydrazine hydrate, heated at 80°C for 10 hours to obtain a precursor solution;

[0037] 4) Immerse the ceramic interdigitated gold electrode in step 1) in the precursor solution prepared in step 3) for 1.5 minutes, pull it out, and heat it at 90°C for 5 hours to obtain a composite moisture-sensitive electrode covered with polyelectrolyte and graphene. Thin film resistive humidity sensor.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com