Structural color contact lens based on coffee ring effect and preparation method thereof

A contact lens and coffee ring technology, which is applied in glasses/goggles, applications, and other household appliances, can solve the problems of low reliability and insufficient wearing of glasses, and achieve simple process, low preparation cost, and good practicability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] The preparation of embodiment 1PHEMA structural color contact lens

[0038] 1. Preparation of colloidal solution:

[0039] Add the monodisperse dry powder of silica colloidal nanoparticles with methyl groups on the surface to absolute ethanol solution, adjust the colloidal particle concentration to 0.015g / ml, and ultrasonically disperse to obtain a uniform silica colloidal particle solution;

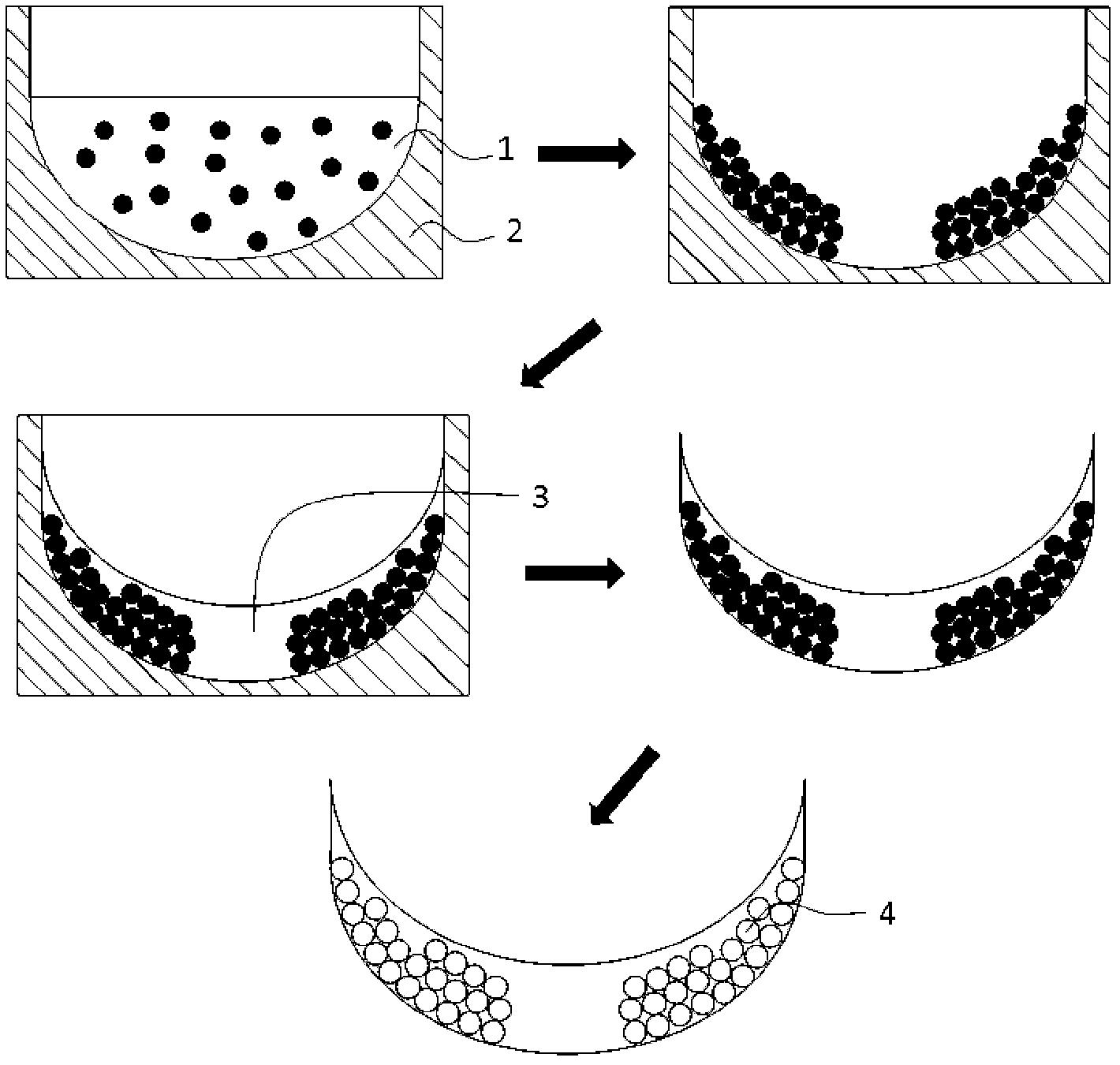

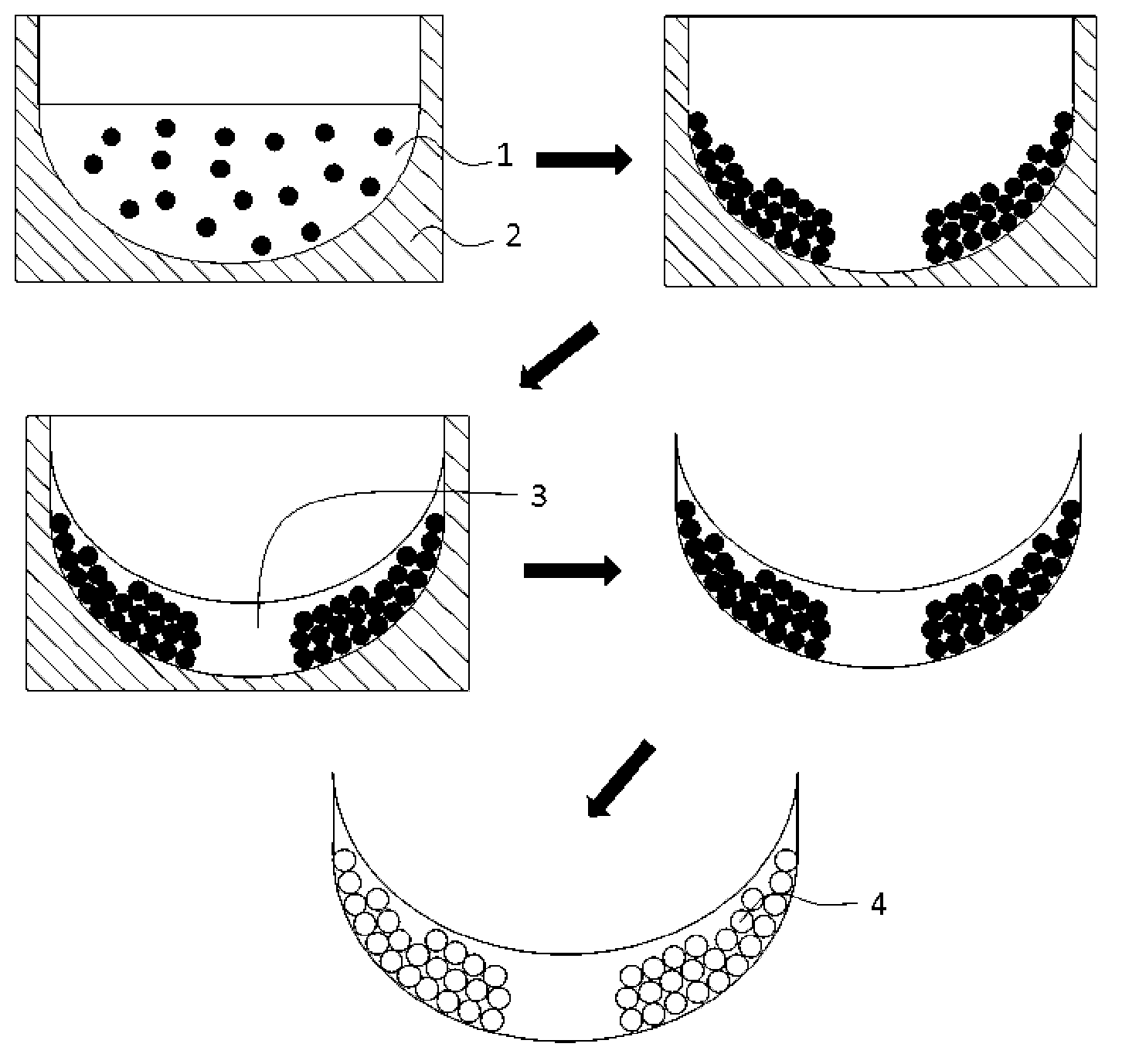

[0040] 2. Assembly of colloidal particles on the inner wall of the mold:

[0041] Add 200 microliters of ethanol solution (0.015g / ml) of silicon dioxide colloidal particles into the mold used for contact lens preparation, place it in an oven at 100°C and keep it for 15 minutes, and the colloidal particles will be assembled in the mold as the ethanol volatilizes. A ring-shaped uniform and orderly close-packed colloidal crystal film, leaving a circular blank area with a diameter of 0.45 cm in the center of the bottom;

[0042] 3. Curing and hydration treatment of structural colore...

Embodiment 2

[0044] Embodiment 2 The adjustment of the size of the pupil region of the contact lens

[0045] Step 3 is the same as Example 1, and the size of the pupil area can be adjusted by adjusting the concentration of silicon dioxide particles and the volume added to the mold. In step 1, when changing the concentration of silica particles to 0.005, 0.01, 0.015, and 0.02 g / ml respectively, the size of the pupil area of the contact lens obtained is 0.58, 0.55, 0.45, and 0.35 cm; in step 2, when changing When the volume of the silicon dioxide particle solution added is 150, 200, 250, 300 ul respectively, the size of the pupil area of the obtained contact lens is 0.49, 0.45, 0.43, 0.38 cm.

Embodiment 3

[0046] The color adjustment of embodiment 3 contact lenses

[0047] Steps 2 and 3 are the same as in example 1. In step 1, structural color hydrogel contact lenses with main colors of different reflection colors can be prepared by adjusting the diameter of silica particles.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com