Self-locking fuel cell sealing assembly structure

A technology for fuel cells and sealing components, which is applied to battery pack parts, electrical components, structural parts, etc., can solve problems such as auxiliary sealing methods that are not considered, achieve easy processing technology, realize processing technology, and improve stability and safety sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

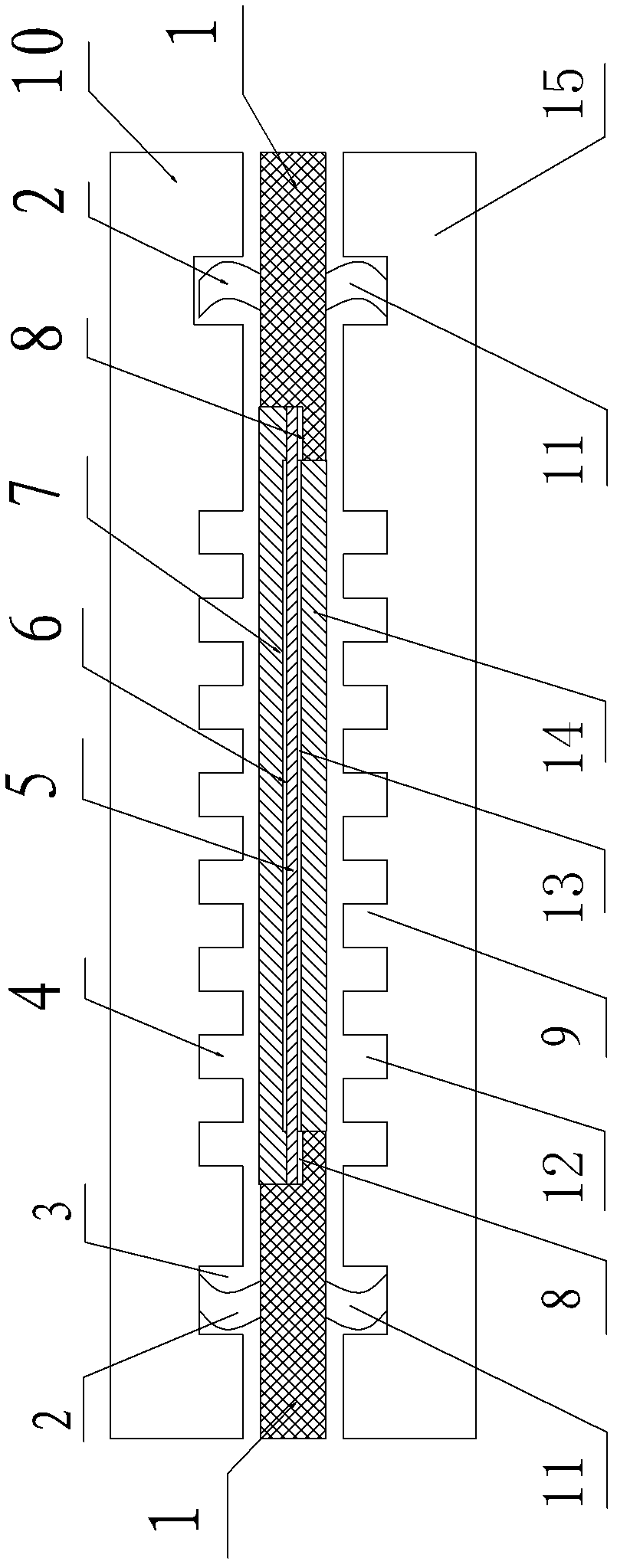

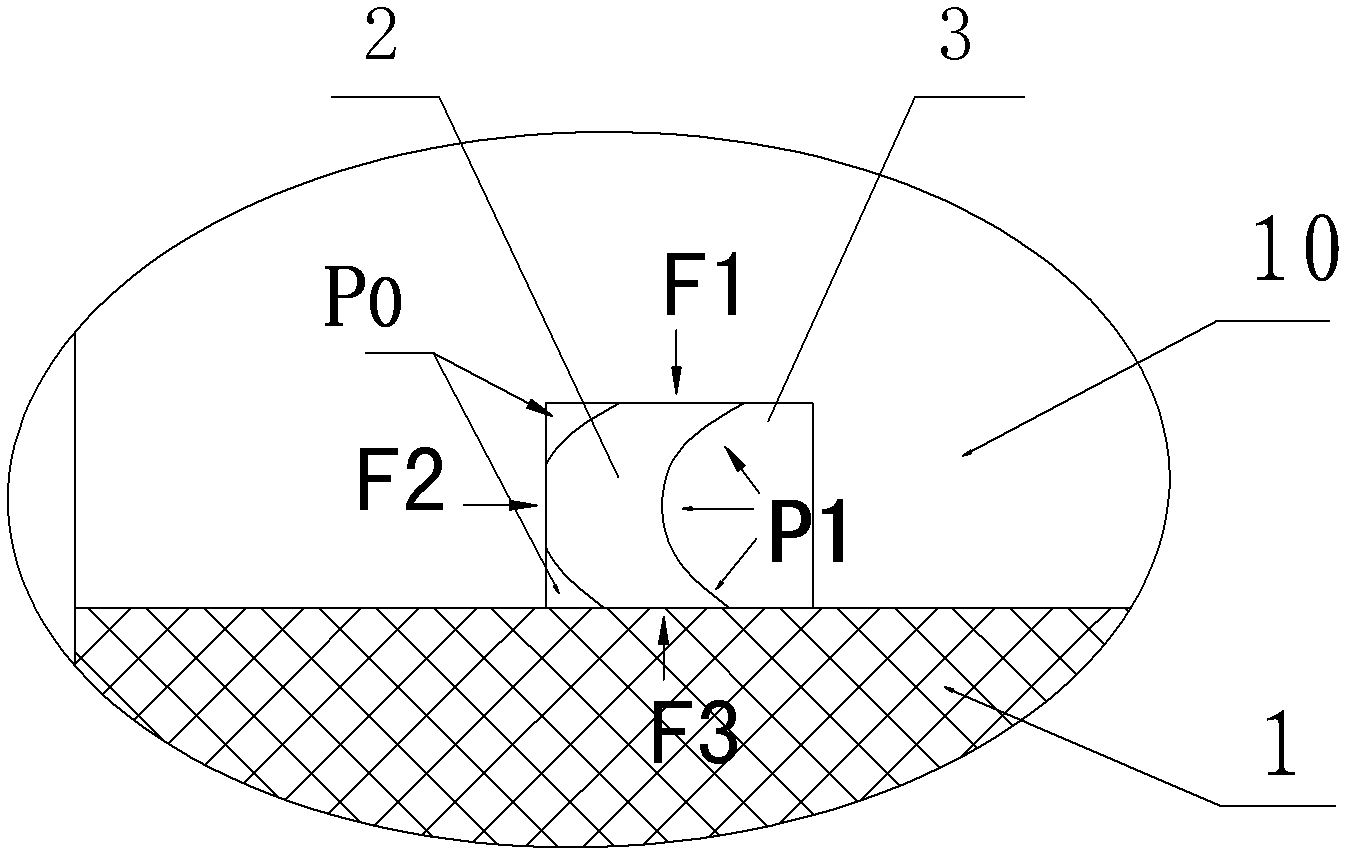

[0039] Such as Figure 1-5 As shown, a self-locking fuel cell sealing assembly structure, which involves a fuel cell cell, the fuel cell cell includes a bipolar plate and a membrane electrode assembly; the bipolar plate is composed of an upper unipolar plate 10 and a lower unipolar plate 15 , the upper unipolar plate 10 is provided with an upper flow channel 4 and an upper sealing channel 3, the upper channel 4 is located inside the annular upper sealing channel 3, an upper sealing ring 2 is provided in the upper sealing channel 3, and the lower unipolar The plate 15 is provided with a lower flow channel 12 and a lower sealing channel 16, the lower flow channel 12 is located inside the annular lower sealing channel 16, the lower sealing channel 16 is provided with a lower sealing ring 11, and the membrane electrode assembly is located in the upper unipolar Between the plate 10 and the lower unipolar plate 15, the upper channel 4 and the lower channel 12 are located at the memb...

Embodiment 2

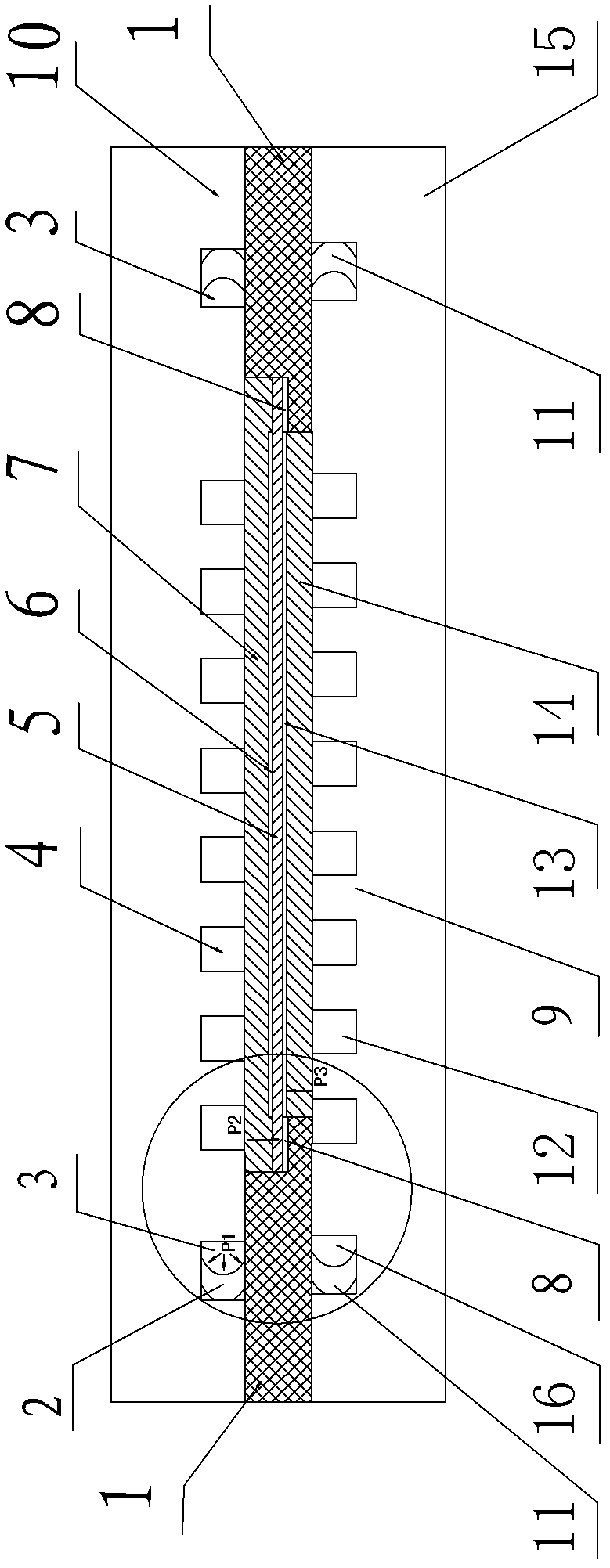

[0047] Such as Figure 6 Shown, a kind of self-locking fuel cell sealing assembly structure (another scheme), it relates to fuel cell monomer, and fuel cell monomer comprises bipolar plate, membrane electrode assembly; Bipolar plate is made up of upper unipolar plate 10 and lower Composed of unipolar plates 15, the upper unipolar plate 10 is provided with an upper flow channel 4, and the upper unipolar plate 15 is provided with a lower flow channel 12; the membrane electrode assembly is located between the upper unipolar plate 10 and the lower unipolar plate 15; The membrane electrode assembly includes a membrane electrode support part 1, a proton exchange membrane 5, an upper catalyst layer 6, an upper gas diffusion layer 7, a lower catalyst layer 13, and a lower gas diffusion layer 15. The membrane electrode support part 1 has a ring structure, and the membrane electrode support part 1 is provided with an annular support step on the inner wall of the annular chamber, the edg...

Embodiment 3

[0055] It is basically the same as Embodiment 2, the difference is that: the lower unipolar plate 15 is provided with a lower sealing channel 16 (the upper unipolar plate 10 is not provided with an upper sealing channel 3), and the lower flow channel 12 is located at the bottom of the ring. The inner side of the sealing channel 16, the lower sealing channel 16 is provided with a lower sealing ring 11, the cross-sectional shape of the lower sealing ring 11 is concave, the concave part of the lower sealing ring 11 faces the gas flow field area, and the lower flow channel 12 is located at At the membrane electrode supporting part 1 of the membrane electrode assembly, the upper unipolar plate 10 and the membrane electrode supporting part 1 of the membrane electrode assembly are bonded and fixed by the second sealing adhesive layer 17 .

[0056] The cross-sectional shape of the lower sealing ring 11 is V-shaped, C-shaped or U-shaped.

[0057] The number of the lower sealing grooves...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com