Oil-in-water emulsion containing lactic acid fermentation emulsion

A technology of oil-in-water emulsion and lactic acid fermentation, which is applied in the production/processing of edible oil/fat, edible oil/fat phase, and edible oil/fat, and can solve resource constraints, cost usage restrictions, and complicated steps, etc. problem, to achieve the effect of rich milk flavor and mellow taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

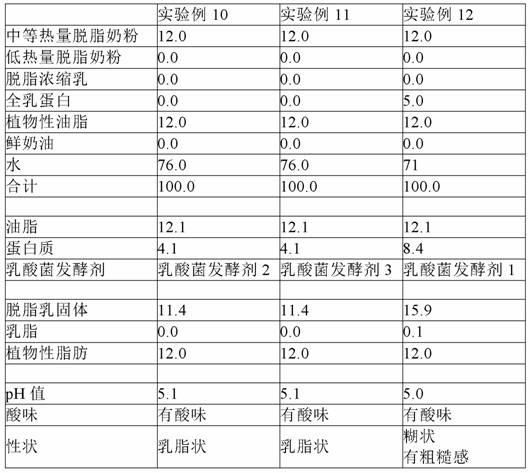

[0055] Hereinafter, the present invention will be described in more detail through the examples of the present invention, but the gist of the present invention is not limited by the following examples. In addition, in the Example, "%" and "part" both represent a weight basis.

[0056] Evaluation method for oil-in-water emulsions.

[0057] The viscosity of the oil-in-water emulsion and the plasticization test (stability of the oil-in-water emulsion) were evaluated.

[0058] Viscosity: The viscosity of the oil-in-water emulsion was measured using a Brookfield viscometer (manufactured by Tokyo Keiki Co., Ltd.) using a No. 2 rotor under the condition of 60 rpm.

[0059] Plasticization test: 50 g of the oil-in-water emulsion was placed in a 100-ml volume beaker, kept at 20° C. for 2 hours, and then stirred for 5 minutes to confirm whether or not plasticization occurred.

[0060] Evaluation method when oil-in-water emulsion is foamed

[0061] (1) whipping time: whipping 1 kg of t...

experiment example 1

[0081] 12.0 parts of medium heat skimmed milk powder (manufactured by YOTSUBA Co., Ltd.) was mixed with 76.0 parts of water at 40°C, and then 12.0 parts of hardened rapeseed oil was added, and heated while stirring with a homomixer, and carried out at 70°C for 30 It was pre-emulsified in 10 minutes, then homogenized with a homogenizer under a pressure of 10 MPa, and rapidly cooled to 20° C. to prepare an oil-in-water emulsion. The composition of this emulsion was 12.1 wt% oil, 4.1 wt% milk protein, and 76.6 wt% water. To 100 parts of the emulsion thus obtained, 1 part of a lactic acid bacteria starter (mixed bacteria of Streptococcus salivarius subsp. thermophilus and Lactobacillus delbrueckii subsp. bulgaricus) manufactured by Christian Hansen was added, and the fermentation was carried out at 40°C. The time point at 4.4 was rapidly cooled to 5°C to stop fermentation. Next, this fermentation product was immediately heat-sterilized at 80° C. for 10 minutes, and then rapidly c...

experiment example 2

[0083] The method of Experimental Example 1 was carried out except that 12.0 parts of medium-calorie skim milk powder (manufactured by YOTSUBA Co., Ltd.) was changed to 12.0 parts of low-calorie skim milk powder (manufactured by YOTSUBA Co., Ltd.), and the method of Experimental Example 2 was obtained. "Lactic acid fermentation emulsion 2". This "lactic acid fermentation emulsion 2" had a pH value of 4.5 after sterilization and cooling.

[0084] The formulations and results are summarized in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com