Three-segment biological treatment process and device for sewage

A biological treatment and sewage technology, applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc. The effect of low nitrogen and low phosphorus and high requirements, reducing operating costs and reducing operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

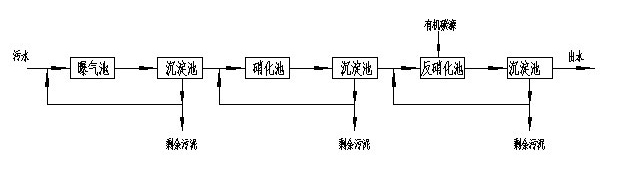

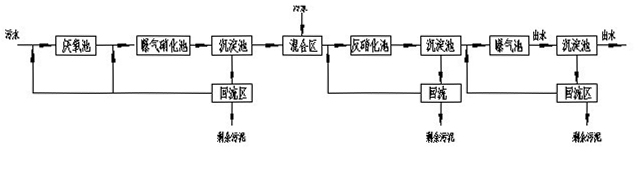

[0027] Embodiment 1: see figure 2 , the three-stage biological treatment process of the present invention has successively an anaerobic phosphorus release treatment unit independently connected in series, an organic matter oxidation and nitrification (aeration nitrification) treatment unit, a second influent mixing unit, a denitrification treatment unit, an organic matter oxidation (aeration nitrification) treatment unit, and an organic matter oxidation (aeration nitrification) treatment unit. Pool) treatment unit, each treatment unit has its own settling tank and self-reflux system, that is, the sedimentation sludge in each section is discharged into another sludge thickening tank except for part of it returning to the treatment unit in this section. Thus, a three-stage biological treatment process with three-stage treatment characteristics is formed.

[0028] Treatment process: Most of the sewage is treated and enters the anaerobic unit. Phosphorus release is completed in t...

Embodiment 2

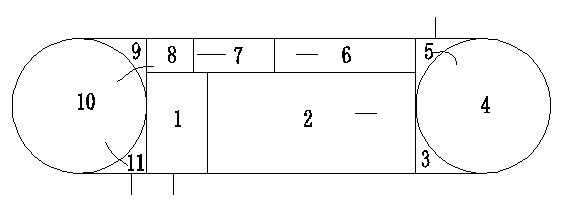

[0029] Example 2: see image 3 , the three-section biological treatment device for sewage of the present invention (described from the left end to the right end), separates the two ends of the width of the rectangular pool and connects two circular sedimentation areas 10 (aerobic sedimentation) and 4 (aerated nitrification sedimentation) smoothly respectively on both sides, in the middle The partitioned rectangular pool is axially separated by a partition (wall) offset to separate two rectangular areas with different widths (the ratio between the large rectangular area and the small rectangular area is 2-3:1). The large rectangular area is adjacently divided into a small anaerobic area 1 and a large aerated nitrification area 2 (the ratio of the two is 6-8:1); the small rectangular area is divided into adjacent aeration areas 8, sedimentation Zone 7 (anoxic precipitation), denitrification zone 6, in which inclined tubes or inclined plates are built in the precipitation zone 7 ...

Embodiment 3

[0031] Embodiment 3: As mentioned above, depending on the quality of treated water, the functions of some areas can also be changed to meet the requirements of sewage treatment to the greatest extent. For example, when treating sewage with high ammonia nitrogen and low phosphorus, the nitrification liquid in the aeration nitrification zone 2 can be returned to the anaerobic zone 1 by adding nitrification liquid backflow equipment, so that the anaerobic zone becomes an anoxic denitrification denitrification zone, so that the process has Secondary denitrification denitrification (zone 1 and zone 6) to improve the biological denitrification capacity; when the sewage is low in ammonia nitrogen and high in phosphorus, the denitrification zone 6 becomes an anaerobic zone by controlling the dissolved oxygen adjustment device in it. Anaerobic phosphorus release, and adding an aeration device in the denitrification precipitation zone 7, removing the original sedimentation sloping plate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com