Method for preparing isobutylene by etherification

A technology of isobutylene and etherification, applied in the direction of producing hydrocarbons from oxygen-containing organic compounds, etc., can solve the problems of high energy consumption, high reaction temperature, single product, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] The separation of isobutene in the C4 fraction by etherification is divided into two steps:

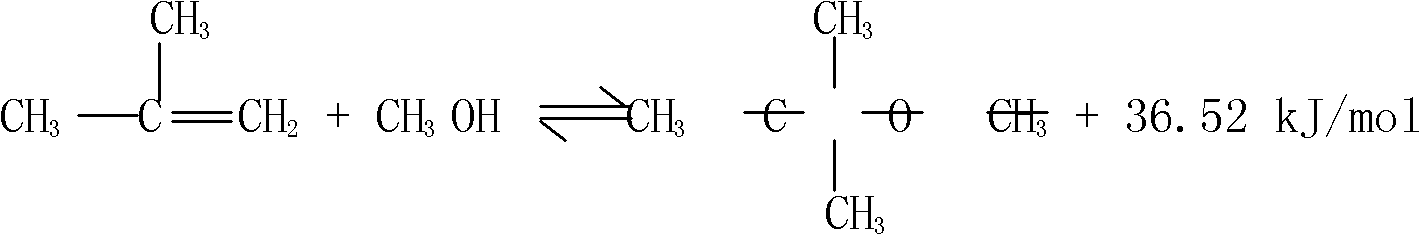

[0037] The first step is the reaction of isobutylene and methanol in the C4 fraction to generate methyl tert-butyl ether (MTBE) under the catalysis of strongly acidic cation exchange resin;

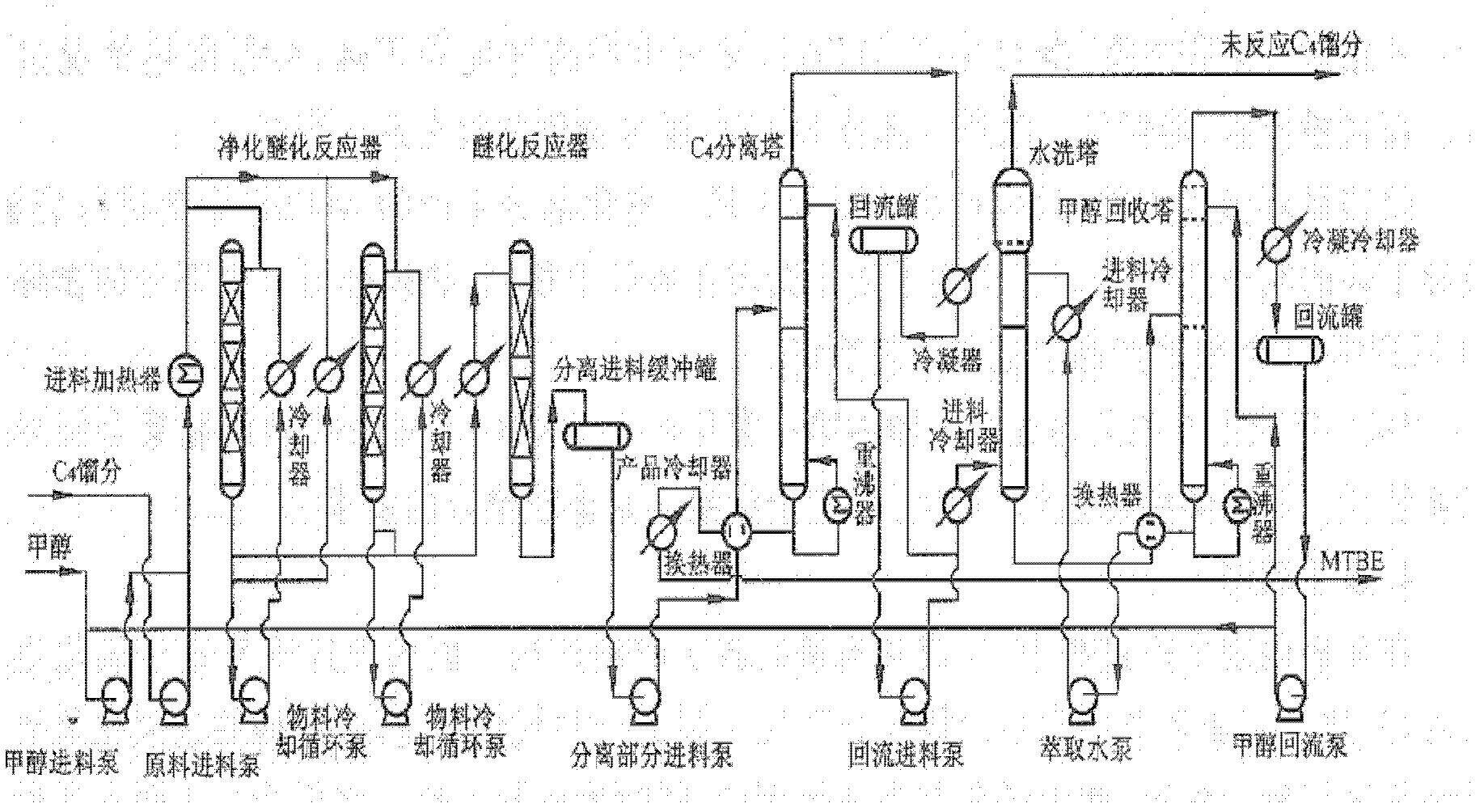

[0038] The second step is to crack MTBE. The reaction of isobutene and methanol etherification into MTBE is reversible, so under appropriate conditions, MTBE can be decomposed into high-purity isobutene and methanol in contact with acidic catalysts. There are four types of acidic catalysts: supported sulfate catalysts, solid phosphoric acid catalysts Or ion exchange resin catalyst, see process for details figure 1 .

Embodiment 2

[0040] The separation of isobutene in the C4 fraction by etherification is divided into two steps:

[0041] The first step is the reaction of isobutylene and methanol in the C4 fraction to generate methyl tert-butyl ether (MTBE) under the catalysis of strongly acidic cation exchange resin;

[0042] The second step is to crack MTBE. The reaction of isobutene and methanol etherification into MTBE is reversible, so under appropriate conditions, MTBE can be decomposed into high-purity isobutene and methanol in contact with acidic catalysts. Among them, there are four types of acidic catalysts: supported sulfate catalysts, solid phosphoric acid catalysts or Ion exchange resin catalyst, see process for details figure 1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com