Liquid-state steel slag micronization recycling device

A recovery device and a technology for liquid steel slag, applied in the field of liquid steel slag micronization recovery device, can solve the problems of weak processing capacity of the micronization device, unsuitable for the field of waste slag recovery, low sensible heat resource recovery rate, etc. The effect of energy consumption and flight distance reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

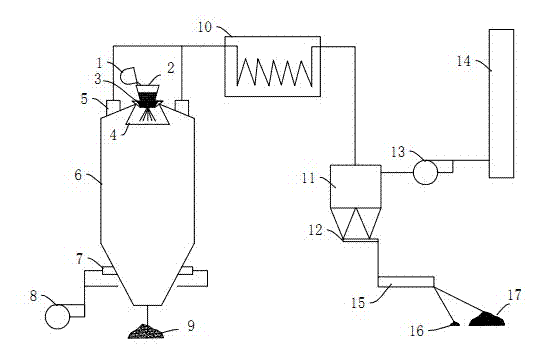

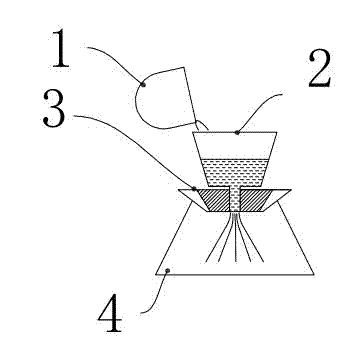

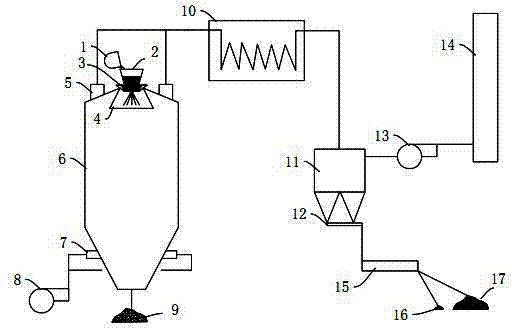

[0034] refer to figure 1 , liquid steel slag micronization recovery device, comprising a pulverization heat exchange chamber 6, a launder 2, an annular tapering nozzle 3, and a nozzle cover 4, the annular tapering nozzle 3 is arranged on the top of the pulverization heat exchange chamber 6, and the The launder 2 is arranged on the annular tapering nozzle 3, the nozzle cover 4 is arranged at the outlet of the annular tapering nozzle 3, the top of the pulverization heat exchange chamber 6 is provided with an air outlet 5, and the bottom of the pulverization heat exchange chamber 6 is Equipped with cold air inlet 7 and bottom slag outlet;

[0035]Also include blower 8, heat exchanger 10, dust remover 11, induced draft fan 13, chimney 14, described blower 8 is connected with cold air inlet 7, and described heat exchanger 10 is communicated with air outlet 5, dust remover; The induced draft fan 13 communicates with the dust collector 11 and the chimney 14. The dust collector 11 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com