Construction method of separation wall for carrying out in situ separation repair on pollution site

A construction method and separation wall technology, applied in artificial islands, water conservancy projects, infrastructure engineering, etc., can solve the problems of aggravated wall damage, low wall resistance to corrosion damage, workability increases with age, etc., to achieve The construction method is simple, the wall integrity is avoided, and the effect of shortening the effective time of isolation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

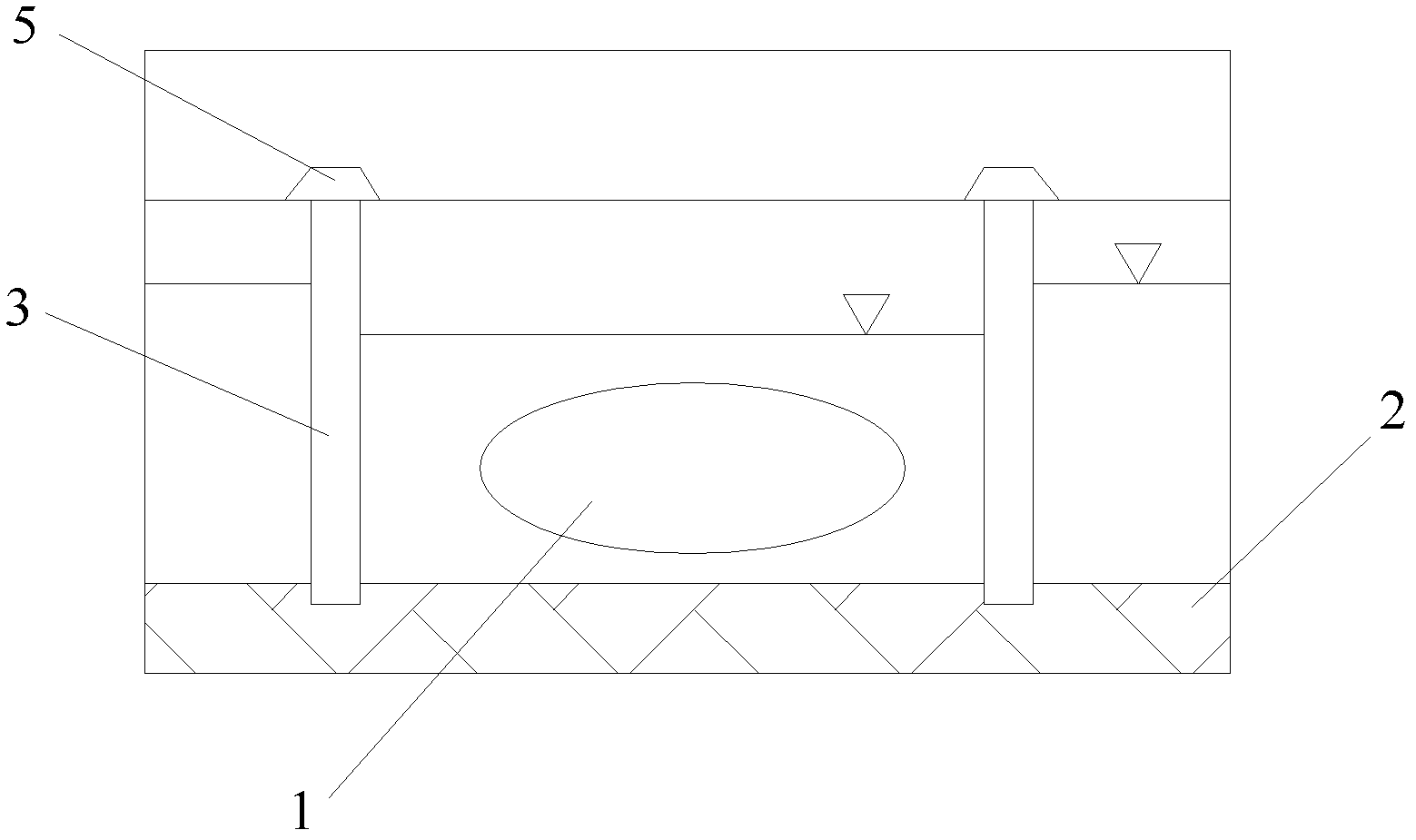

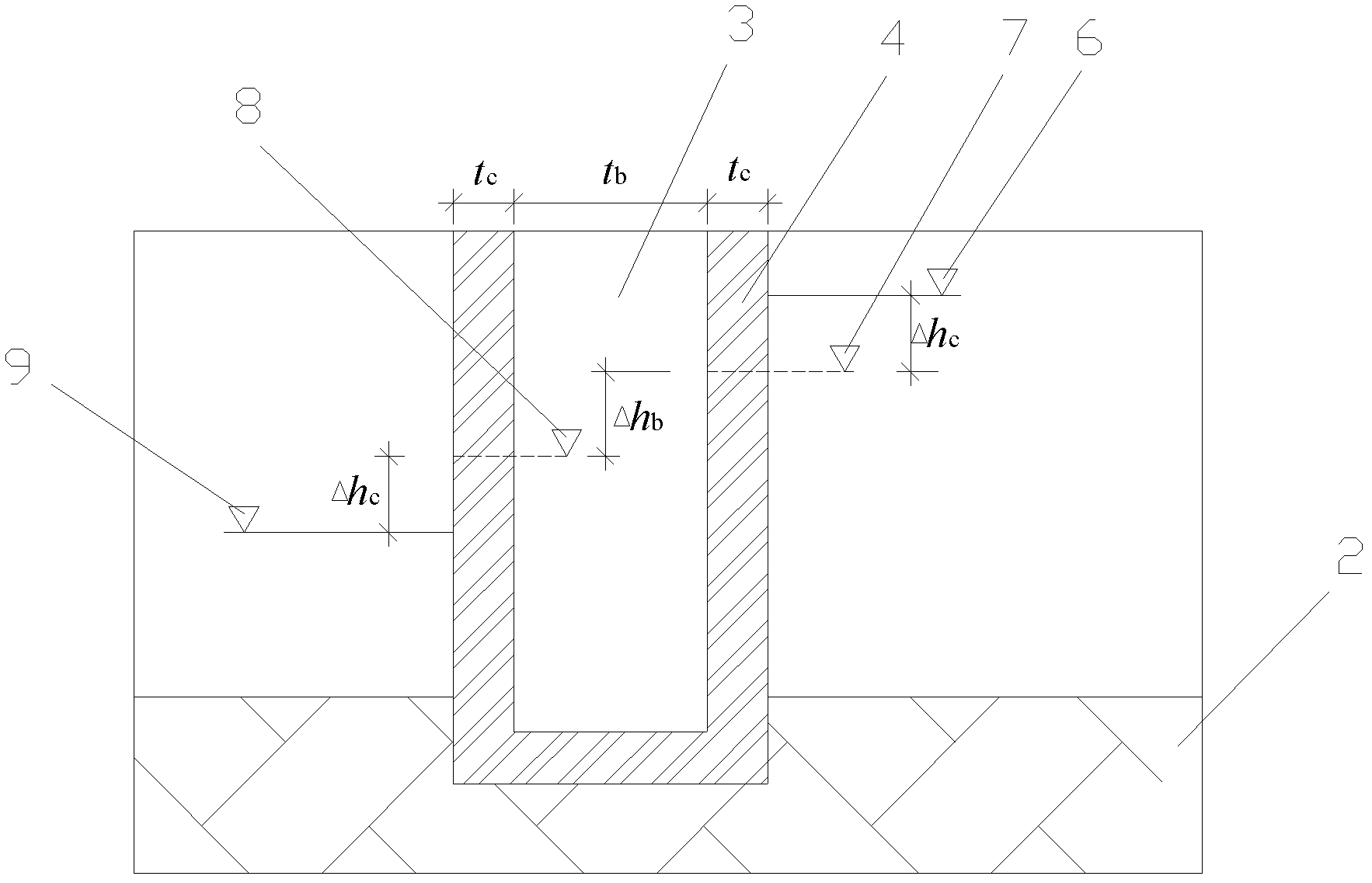

[0022] The technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0023] A separation wall for in-situ isolation and repair of polluted sites according to the present invention, the separation wall 3 is composed of uncontaminated in-situ soil and bentonite, wherein the mass ratio of uncontaminated in-situ soil and bentonite is 95:5 to 85:15.

[0024] The separation wall 3 in the present invention does not use cement material, but uses bentonite instead of cement, and its impermeability can reach or even exceed the original separation measures using cement as material.

[0025] Further, the top of the separation wall 3 is provided with a geomembrane 5 , and the width of the bottom surface of the geomembrane 5 is greater than the width of the top surface of the separation wall 3 . Adding the geomembrane 5 is mainly to reduce the cracking at the top of the separation wall 3 due to the dry-wet cycle.

[002...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com