Bone graft capable of being directly implanted into intervertenral space and production tool thereof

A technology for making tools and intervertebral, which is applied in the field of forming molds for intervertebral bone grafting. It can solve the problems of inability to effectively support and maintain intervertebral height, loss of height of grafted bone blocks, and failure of fusion, so as to achieve good bone fusion and good bone quality. Conductivity, simple and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

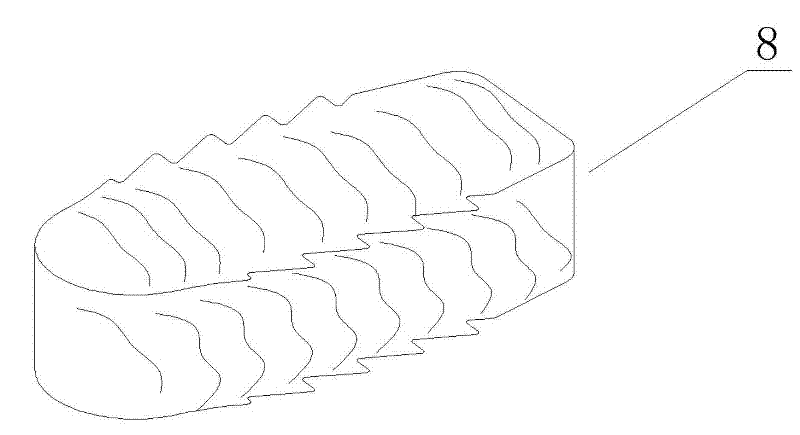

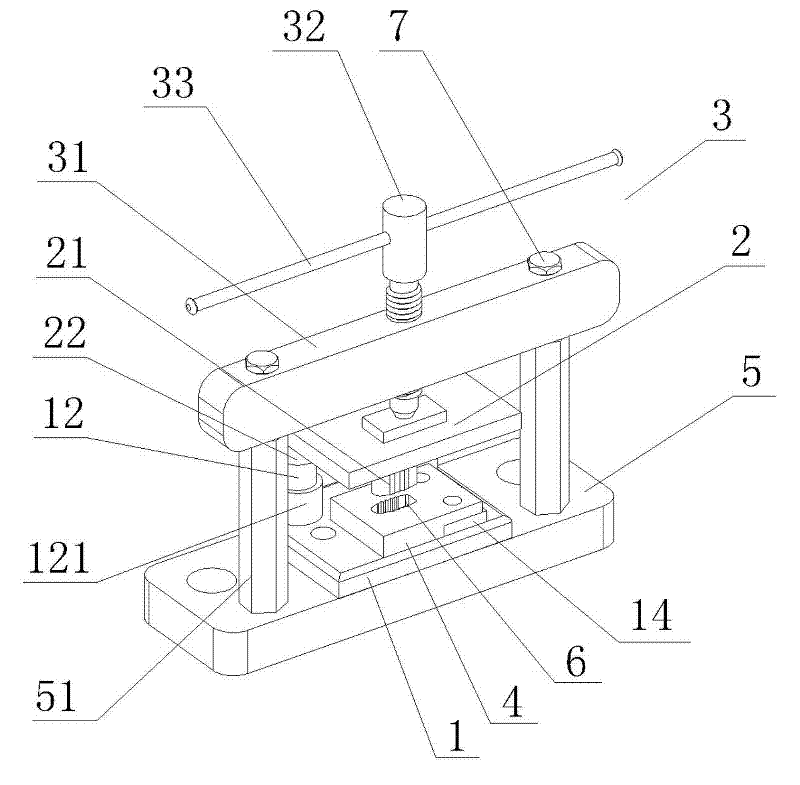

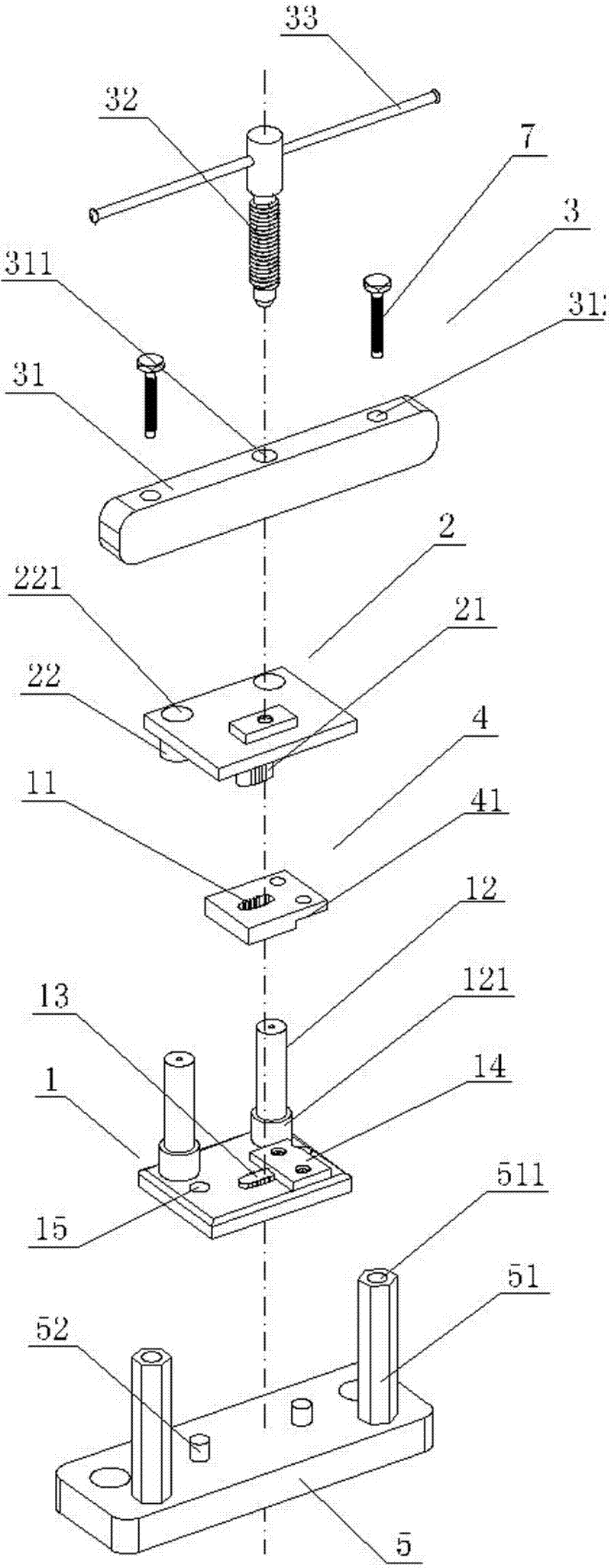

[0017] Such as figure 1 As shown, a bone graft block that can be directly implanted between the vertebrae, the bone graft block 8 is compacted into the required shape from the bone fragments obtained from intraoperative decompression by corresponding production tools. The bone fragments obtained by the decompression are compacted into the bone graft block 8 of the required shape by the corresponding production tools, and the bone graft block 8 can be directly implanted in the intervertebral space. The compressed bone graft block 8 is biomechanically determined It has a certain degree of resistance to pressure, can effectively support and maintain the height of the intervertebral, and is not easy to break, and has high safety. Moreover, the bone graft block 8 is autologous bone, so it has good osteoconductivity and osteoinductivity. After implantation in the intervertebral space The fusion time is short, the healing rate is high, and there is no rejection reaction. There is no ne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com