High notched impact PA/ASA alloy material and its preparation method

A technology of notched impact and alloy materials, which is applied in the field of high notched impact PA/ASA alloy materials and its preparation, which can solve the problems of different synthesis and achieve the effects of improved weather resistance, outstanding notched impact performance, and excellent processing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-3

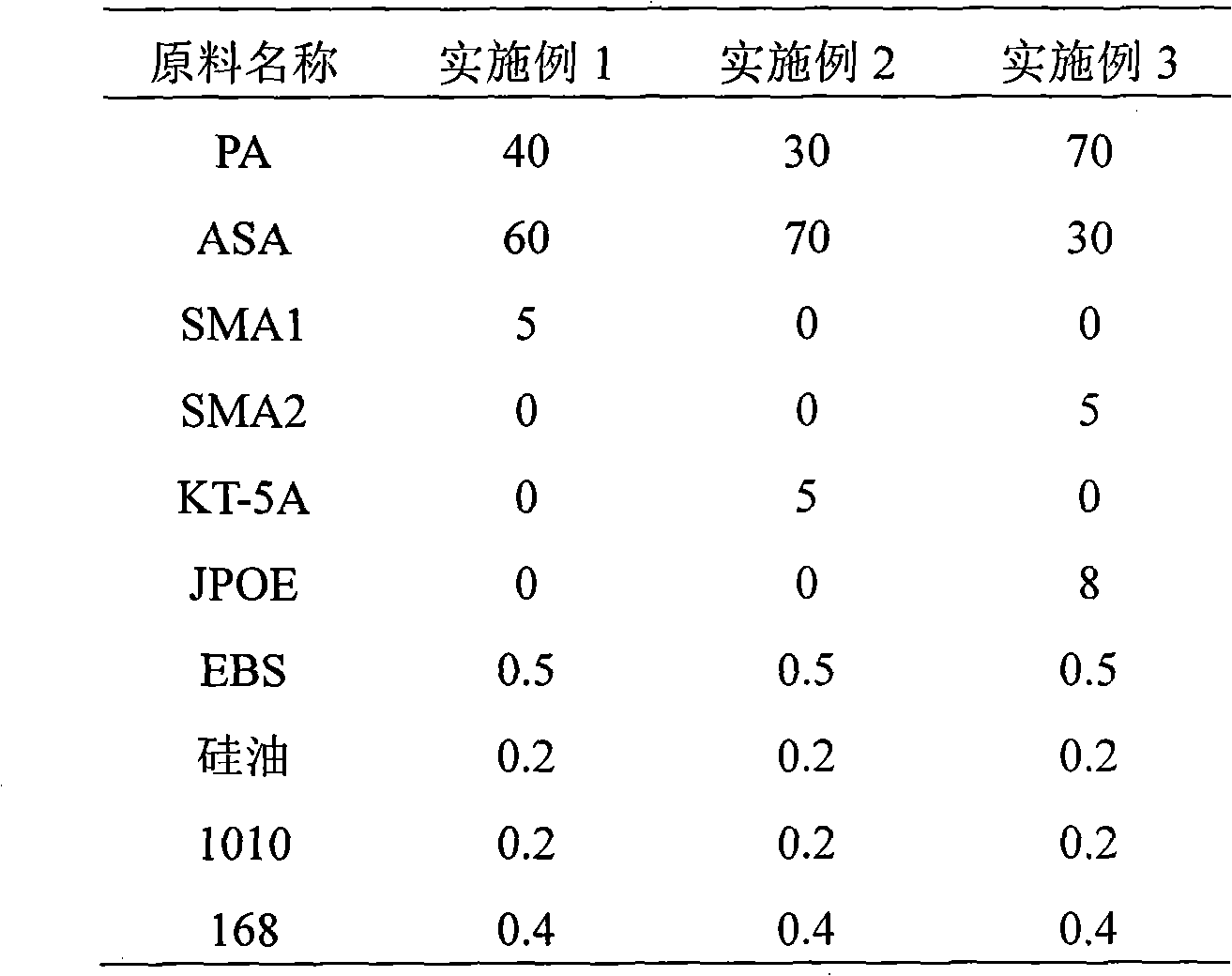

[0034] The formula of embodiment 1-3 is shown in table 1.

[0035] Table 1

[0036]

[0037] All the components of Examples 1-3 in the above table were added in proportion to the high-speed mixer and then discharged after stirring for 3 minutes, and then pelletized with a twin-screw extruder. The screw speed of the extruder was 150-900 rpm. min, the processing temperature is 210-280°C.

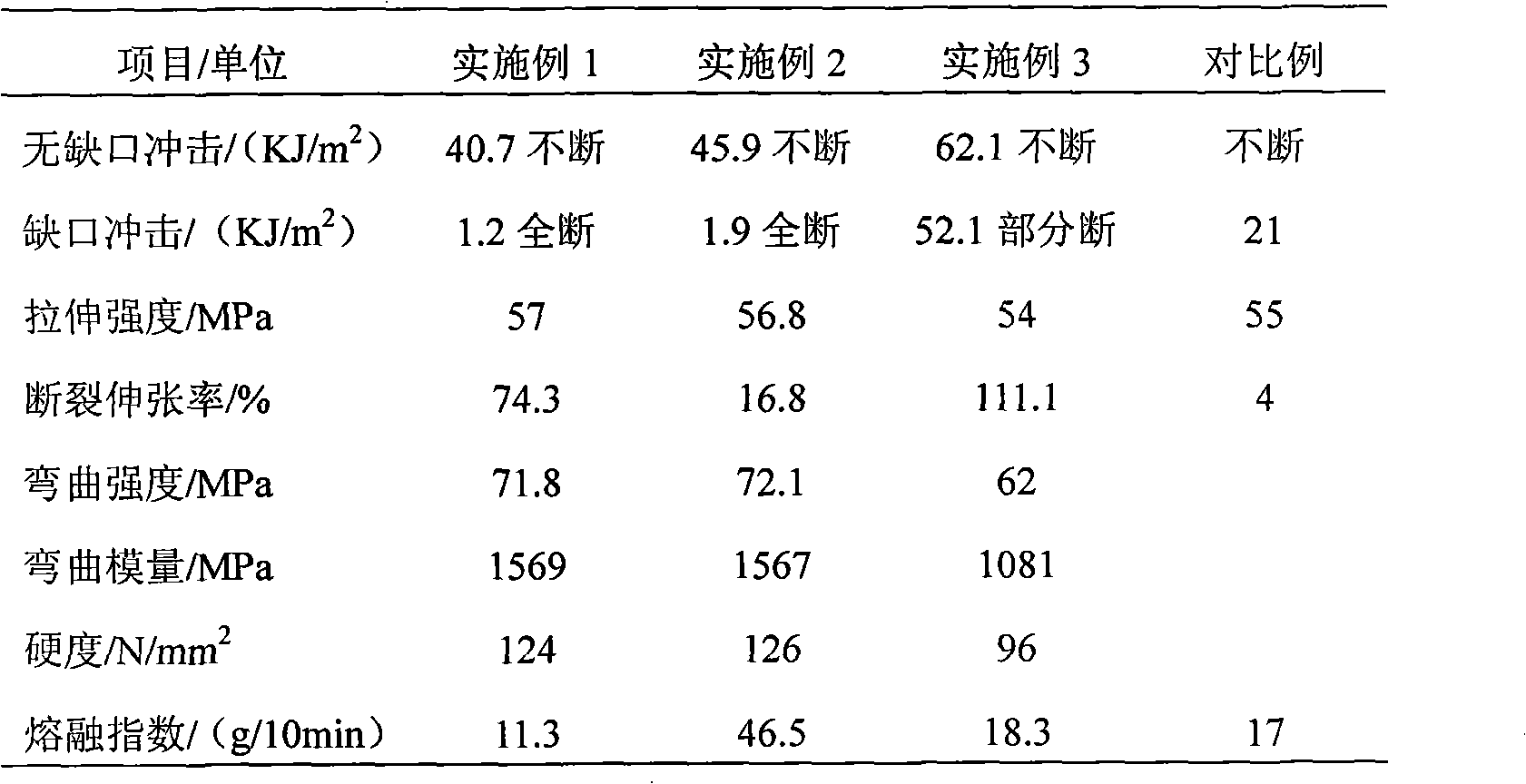

[0038] The above products were prepared according to Examples 1-3, and test samples were prepared according to the same injection molding conditions. The specific injection molding conditions were: injection molding temperature: 220-270° C., injection molding pressure: 40-60 MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com