Electrodeposition electrolytic nickel negative plate

A cathode plate, electrolytic nickel technology, applied in the direction of electrodes, electrolysis process, electrolysis components, etc., can solve the problems of cumbersome production process of starting pole pieces, large investment in personnel and equipment, and high labor production intensity, so as to improve product quality and optimize Production process, the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

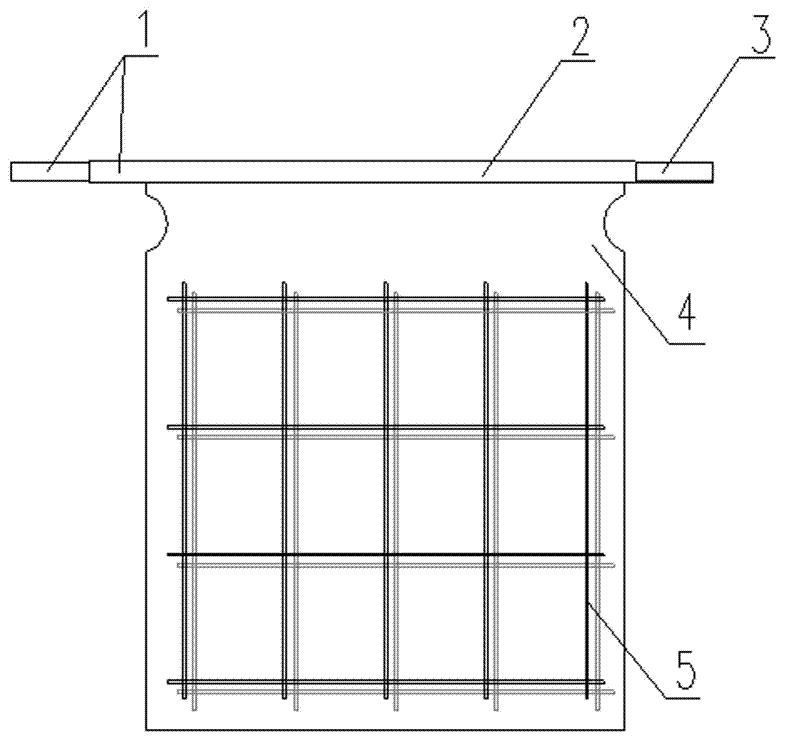

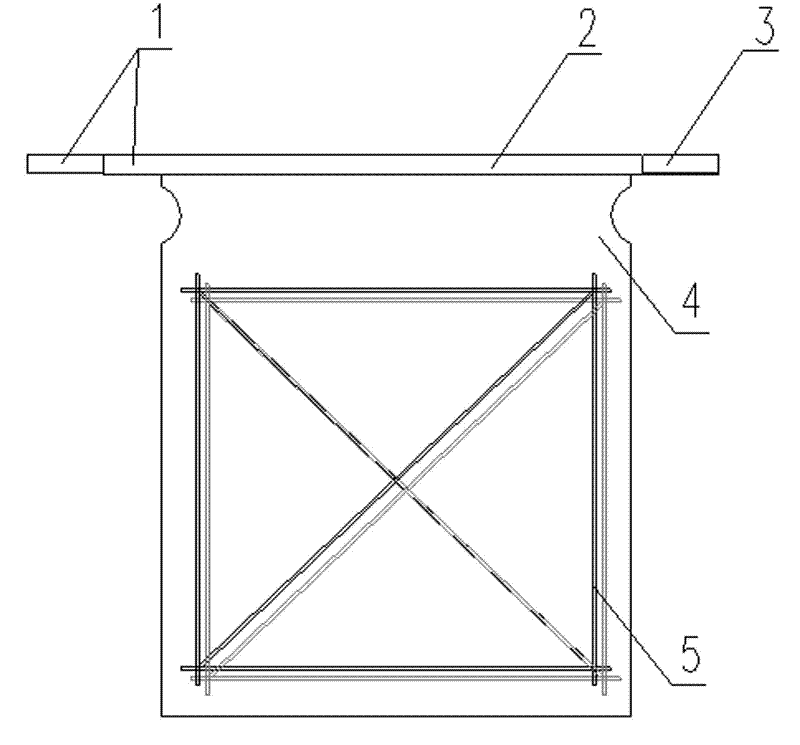

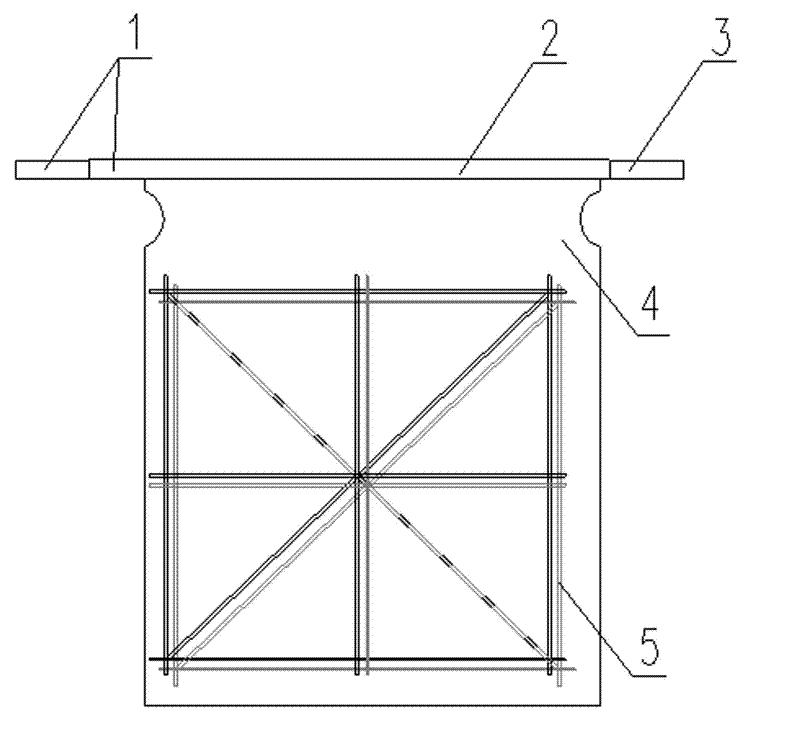

[0023] like figure 1 A cathode plate for electrowinning and electrolytic nickel is shown, comprising a conductive beam 1 and a cathode plate 4, the conductive beam 1 is welded to the cathode plate 4, the conductive beam 1 is a core-clad structure in which a stainless steel 2 wraps a copper rod 3, and the conductive beam 1 is two Remove the stainless steel 2 at the end to expose the copper rod 3, the cathode plate 4 is a stainless steel cathode plate, the bottom of the cathode plate 4 has a split angle 7 with an angle of 50°, the thickness of the cathode plate 4 is 3 mm, and the surface roughness is 6 μm, the cathode plate 4 The surface is processed with attachment grooves 5 with a width of 5.8mm and a depth of 0.35mm, and the attachment grooves 5 form a network structure.

[0024] According to the different grades of nickel products produced, the thickness of the cathode plate in the above embodiment can be adjusted within the range of 2-5 mm, the split angle at the bottom of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com