Valve actuating mechanism on engine

A valve train and engine technology, applied in mechanical equipment, engine components, machines/engines, etc., can solve the problems of complex gear meshing and transmission, and achieve the effect of full inflation, large power and weight, and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to describe the technical content, structural features, achieved goals and effects of the present invention in detail, the following will be described in detail in conjunction with the embodiments and accompanying drawings.

[0021] By common knowledge, we can know: engine engine can be divided into two-stroke engine and four-stroke engine, and two-stroke engine refers to the engine that piston moves two strokes and crankshaft completes one working cycle in the cylinder. A four-stroke engine refers to an engine in which the piston moves four strokes or the crankshaft turns two cylinders to complete one working cycle. Both of these engines can be driven by various materials.

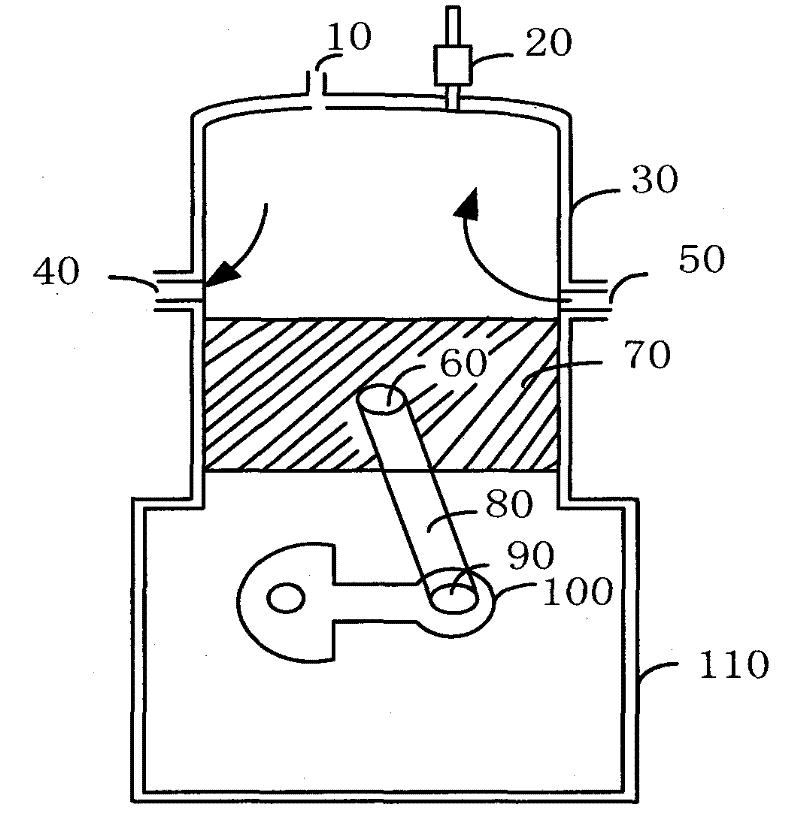

[0022] see figure 1 , in the prior art of the present invention, a structural schematic diagram of an engine, including:

[0023] Oil inlet 10, spark plug 20, cylinder 30, air outlet 40, air inlet 50, tip 60, piston 70, connecting rod 80, crank journal 90, crankshaft 100, crankcase 110. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com