Non-rotary sinking roller for hot-dip galvanization

A sinking roll and hot-dip galvanizing technology, which is applied in hot-dip galvanizing process, coating, metal material coating process, etc., can solve the problem of not fully considering the dynamic changes of the incoming steel strip, the inability to significantly increase the running speed of the steel strip, and the use of Narrow occasions and other issues, to achieve the effect of eliminating contact friction, improving surface quality, and improving overall productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

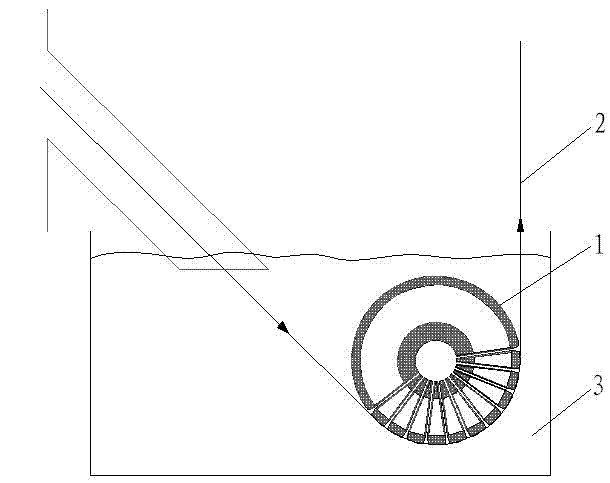

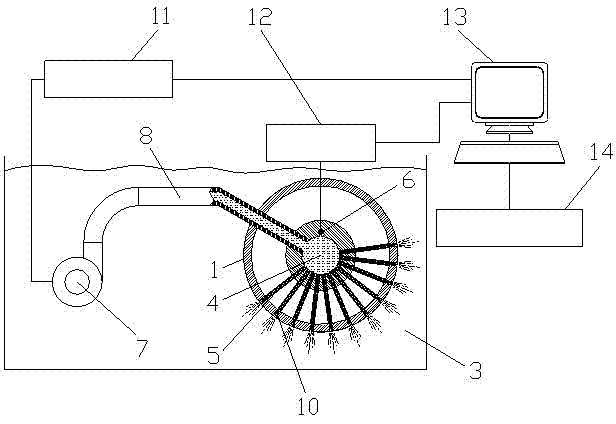

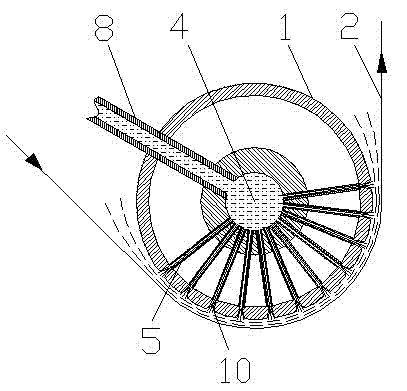

[0020] Such as figure 1 , 2 , 3, and 4, a non-rotating hot-dip galvanized sinking roll, including a fixed sinking roll body 1, an ultra-high temperature pressure gauge 6, a high-temperature zinc pump 7, a guide tube 8, a zinc pump control system 11, a pressure signal The acquisition system 12 and the automatic control system 13, the fixed sinking roller body 1 is fixed and suspended in the zinc pool 3 through the support arms 9 at both ends; the outer surface of the fixed sinking roller body 1 is provided with a matrix of injection ports 10, so The spray port matrix 10 is composed of several spray port arrangements, and the area covered by the spray ports corresponds to the steel strip 2. In this embodiment, the spray angle range of the spray port matrix 10 enters the zinc pool according to the steel strip 2 at the exit of the continuous annealing furnace. The inclination angle at 3 o'clock and the angle between the time when the steel strip 2 leaves the zinc pool 3 are set t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com