Bamboo handrail and production process thereof

A handrail and bamboo tube technology, applied in the field of building decoration materials, can solve problems such as health hazards and environmental pollution, and achieve the effects of adapting to bending and diameter changes, enhancing aesthetics, and short growth cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

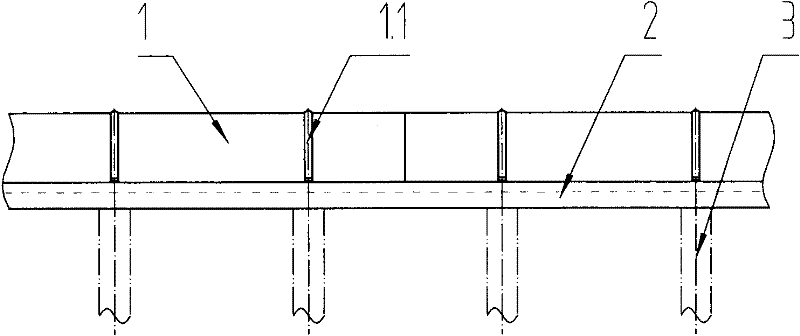

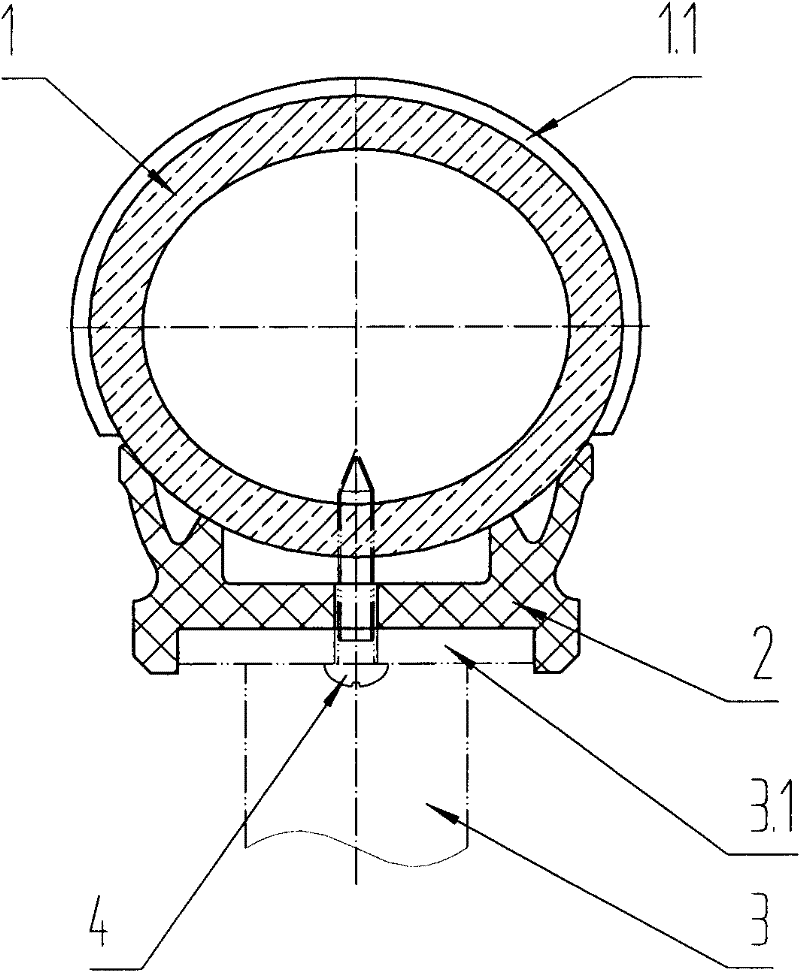

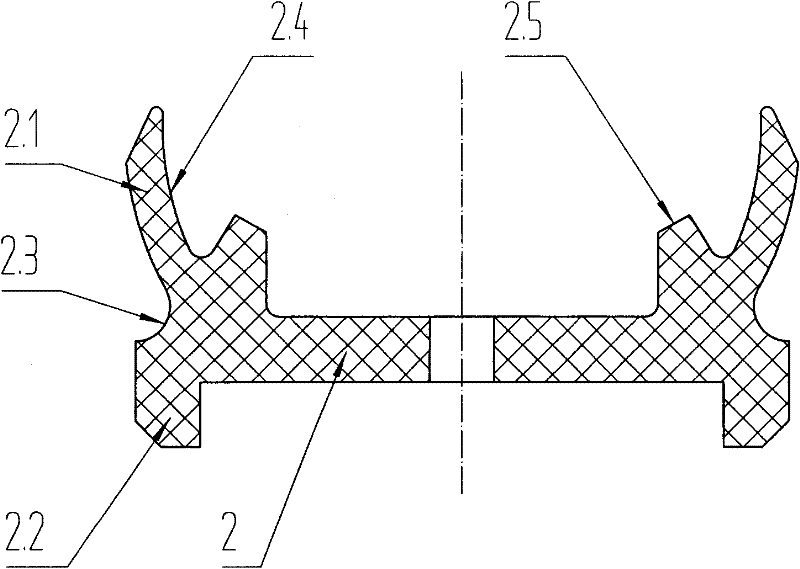

[0047] Such as Figure 1 to Figure 3 As shown, a saddle 2 is provided between the bamboo tube 1 and the railing 3. The saddle 2 is made of elastic materials such as polyurethane and rubber. The saddle 2 is provided with an upper lip 2.1, a lower lip 2.2 and a supporting boss 2.5. The deformability enables the upper lip 2.1 to closely adhere to the surface of the bamboo tube 1. The upper lip 2.1 is provided with an inner arc 2.4 on the inside and an outer arc 2.3 on the outside. In order to enhance the aesthetics and firmness of the fixation, the saddle 2 is provided with a lower lip 2.2. The groove formed by the two lower lips 2.2 is matched with the connecting flat steel 3.1 at the upper end of the railing 3. In order to fix the bamboo tube 1 firmly, there are two supporting bosses 2.5 between the upper lips 2.1 of the saddle 2; the bamboo tube 1 is placed between the two upper lips On the supporting boss 2.5, the connecting flat steel 3.1 is placed between the two lower lips ...

Embodiment 2

[0054] Such as Image 6 , The upper end of the railing 3 is provided with an arc-shaped tray 3.2 that matches the outer diameter of the bamboo tube 1. The bamboo tube 1 is placed on the tray 3.2, and the bamboo tube 1 and the tray 3.2 are fixed by a cable tie 5. The rest is the same as in Example 1.

Embodiment 3

[0056] Such as Figure 7 The upper end of the railing 3 is provided with an arc-shaped tray 3.2 that matches the outer diameter of the bamboo tube 1. The bamboo tube 1 is placed on the tray 3.2, and the bamboo tube 1 and the tray 3.2 are fixed by wood screws 4. The rest is the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com