Polyolefin wood-plastic composite with low rate of water absorption

A technology of wood-plastic composite materials and polyolefin, which is applied in the field of polyolefin wood-plastic composite materials, can solve the problems of wood-plastic composite materials with poor woody appearance, easy mold of wood powder, low content of plant fiber powder, etc., and achieve appearance simulation Good wood effect, high content of plant fiber powder, and improved freeze-thaw resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] 1. Preparation of modified plant fiber

[0059] The quality formula of plant fiber modification is as follows:

[0060] 100 parts of dry plant fiber powder (fir powder, 80 mesh)

[0061] 4 parts flax oil

[0062] The preparation process of modified plant fiber is as follows:

[0063] Drying the plant fiber powder with an airflow cyclone dryer or other drying equipment until the water content is lower than 2%, to obtain a dry plant fiber powder;

[0064] Weigh the plant fiber powder according to the formula and add it to the high-speed mixer, slowly add the metered dry oil while stirring at high speed, stir well and gradually heat up to 100°C, discharge the material, let it stand until the dry oil solidifies, and obtain the modified Vegetable fiber powder.

[0065] 2. Preparation of modified plastics

[0066] The plastic modified quality formula is as follows:

[0067] Recycle 100 copies of waste PE

[0068] 3 parts maleic anhydride

[0069] Styrene 1.5 parts

...

Embodiment 2~5

[0091] The preparation process of Examples 2-5 is the same as that of Example 1, except that the formula is different. The formulations of Examples 2-5 are shown in Table 2 to Table 4.

[0092] Table 2: Preparation formula of modified plant fiber powder

[0093] Example

[0094] Table 3: Preparation formula of modified plastics

[0095] Example

[0096] Table 4: Preparation formula of wood-plastic composites

[0097]

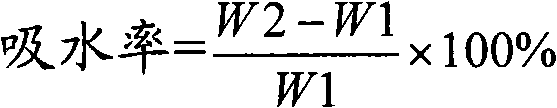

[0098] After testing, the wood-plastic composite materials prepared according to the above formula all have low water absorption (the absorption rate is lower than 3% after soaking in water for 2 months), and have good tensile strength, bending strength and impact strength.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com