Production method of cashmere and woolen sweater thermal underwear

A technology for thermal underwear and a production method, which is applied in the production of woolen sweater thermal underwear and cashmere in the field of clothing, which can solve the problems of low entry threshold, backward technical content, twisted legs and sleeves of clothes, etc., to prevent water deformation, Comfortable and warm

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

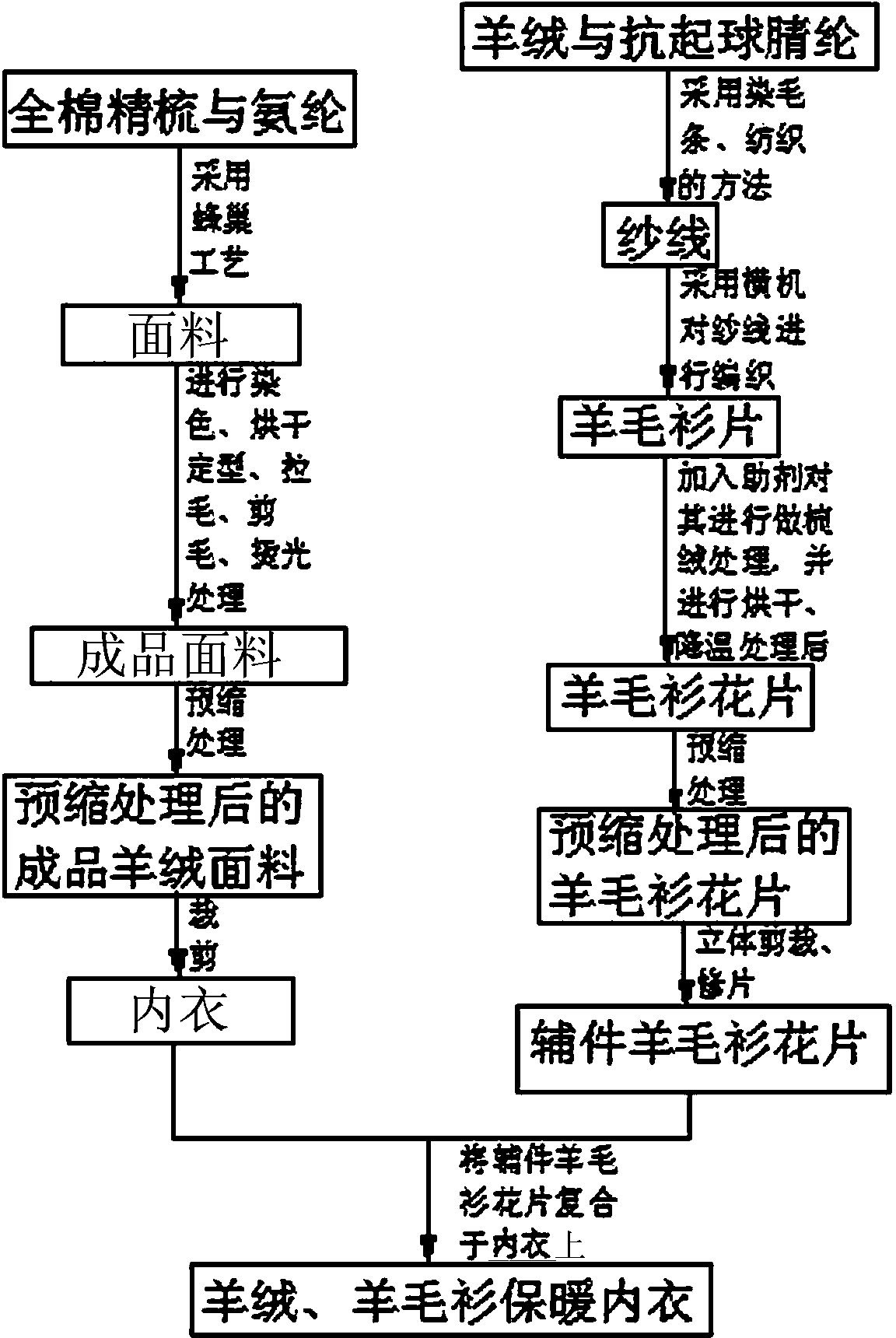

[0025] Such as figure 1 Shown, a kind of method for making cashmere, woolen sweater thermal underwear, comprises following sequential steps:

[0026] 1. Weaving with honeycomb technology to make the fabric of honeycomb tissue;

[0027] 2. Dyeing, drying, setting, napping, shearing and ironing of the fabric to obtain the finished fabric;

[0028] 3. For cashmere and anti-pilling acrylic fibers, yarns are obtained by first dyeing wool tops and then weaving, and then weaving yarns with flat knitting machines to obtain woolen sweaters;

[0029] 4. Carding the woolen sweater piece with additives, drying and cooling to obtain the woolen sweater flower piece;

[0030] 5. Carry out pre-shrinking treatment on the cardigans and fabrics respectively;

[0031] 6. Carry out light embryo inspection on the finished fabrics after pre-shrinking treatment, cut them into underwear, carry out three-dimensional cutting and trimming on the pre-shrinking woolen sweater pieces, make auxiliary woo...

Embodiment 2

[0033] Use different proportions of wool or cashmere and imported anti-pilling acrylic fibers to dye the tops first, and then use worsted spinning or siro spinning to spin them into wool yarns of various specifications from 21 to 56 pounds, and then use imported The flat knitting machine enters into the weaving work of woolen sweater pieces according to the requirements of the process sheet, and then produces the hem of the back piece, cuffs, neckline and other auxiliary parts. After the jacquard pieces of wool and cashmere sweater are completed, different ingredients are added The auxiliary agent is used for carding treatment. Before the fabric is combined with the circular knitting machine, the shrinkage of the fabric produced by the two different equipments will be inconsistent, which will cause the product to be unqualified. This is the most important product in this series. One of the most core technologies, in order to solve this problem, after the two kinds of fabrics ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com