Nuclear-grade large equipment damper

A large-scale equipment and damper technology, applied in the direction of mechanical equipment, shock absorbers, shock absorbers, etc., can solve the problems of unstable working performance, difficulty in adapting to harsh working environments, low radiation resistance, etc., to achieve simple structure, work Stable performance and good radiation resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

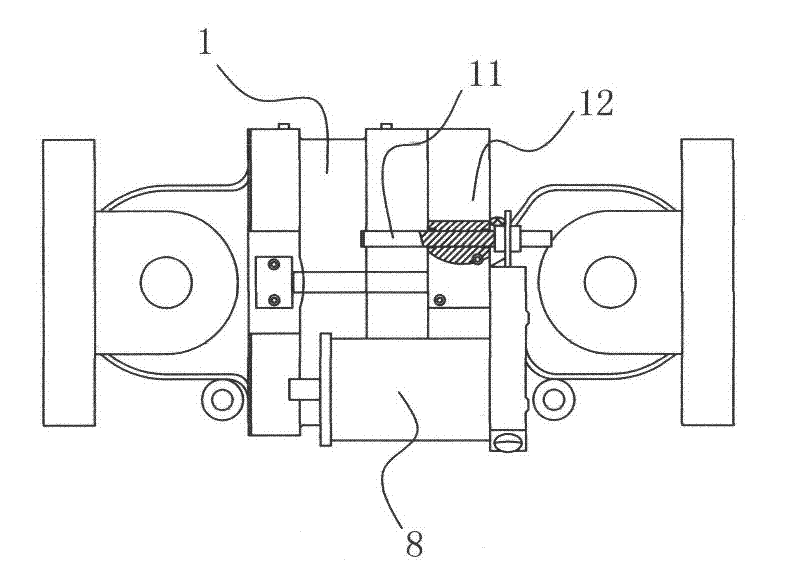

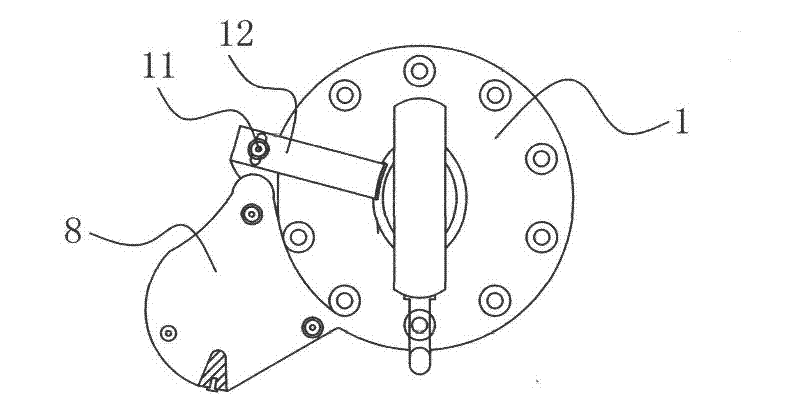

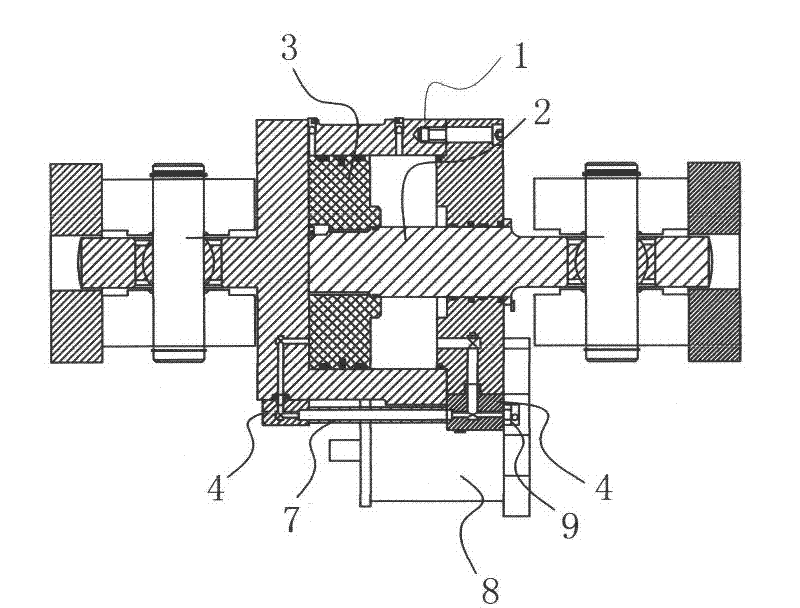

[0020] Such as Figure 1-3 As shown, this nuclear-level large-scale equipment damper includes a damping cylinder 1 equipped with hydraulic medium. A piston rod 2 is inserted in the damping cylinder 1, and the piston rod 2 is provided in the damping cylinder 1 and the damping cylinder 1 Piston 3 is divided into left and right chambers. The outer sides of the two ends of the damping cylinder 1 are respectively provided with valve seats 4, the two valve seats 4 are respectively connected with the oil through holes 10 at both ends of the damping cylinder 1, and the two through oil holes 10 are respectively connected to the left and right chambers of the damping cylinder 1 The chambers are connected, and a valve core 5 with a conical outer end is provided in the valve seat 4 respectively. Such as Figure 4 with 5 As shown, the valve core 5 is provided with a symmetrically distributed throttling structure, a spring 6 is provided between the valve core 5 and the valve seat 4 to press...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com