Rapid and efficient fabric sample cutting device

A cutting device and fabric technology, applied in textiles and papermaking, preparation of test samples, cutting of textile materials, etc., can solve the problems of incompatibility with the requirements of preparation efficiency, high labor intensity, low production efficiency, etc., and achieve fast and efficient Structural conception, easy operation, reasonable structure effect

Active Publication Date: 2012-02-08

中纺标检验认证股份有限公司

View PDF4 Cites 4 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] At present, the above-mentioned textile fabrics with a size no larger than 5mm×5mm are cut by manual scissors, which has low production efficiency and high labor intensity, and does not meet the requirements of sample preparation efficiency in the field of textile testing.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

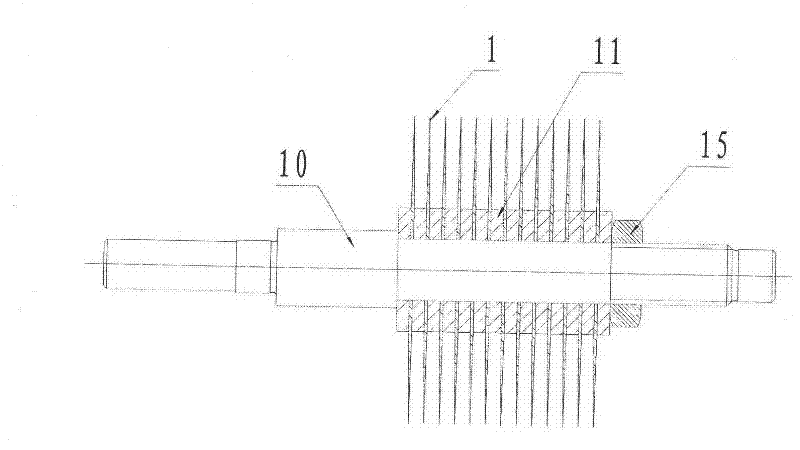

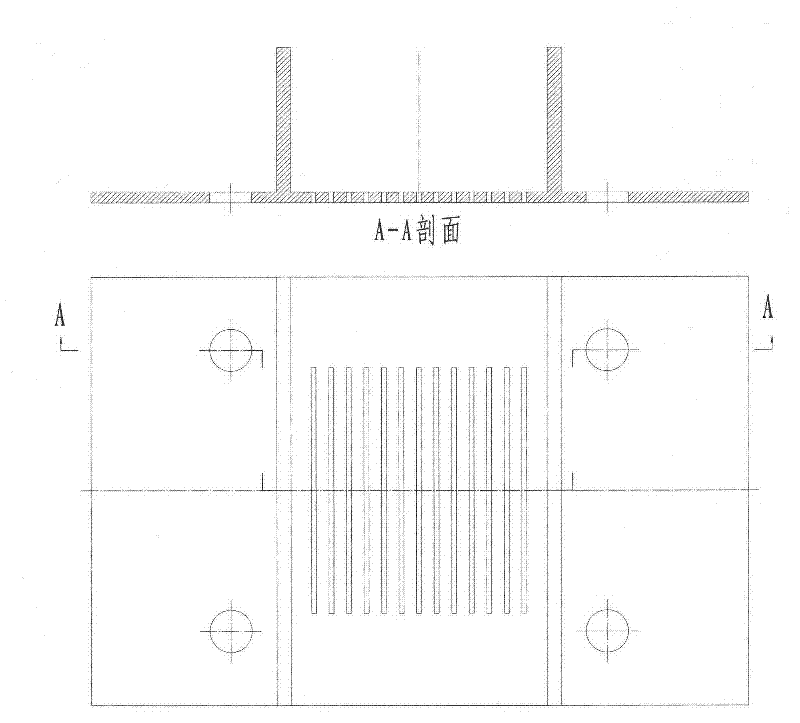

[0041] There are 13 single knives for taking out row knives. The single knives are made of special alloy. The outer dimension width of the support and collection assembly is 80mm, and the inner dimension of the seam row support and collection assembly insert is 80mm.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

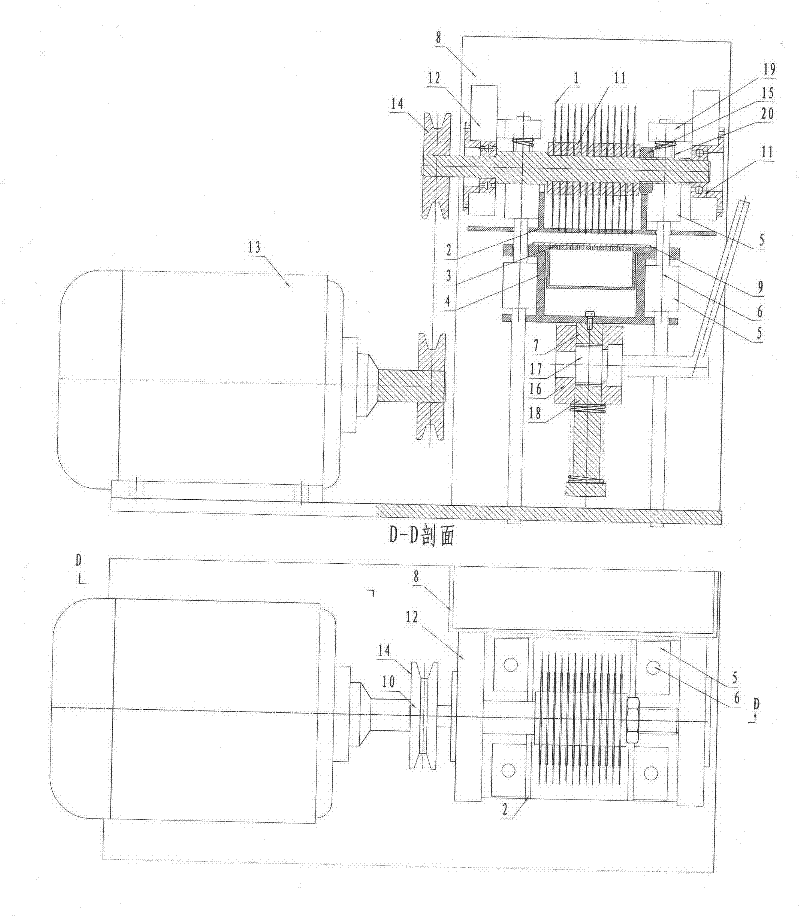

The invention relates to a rapid and efficient fabric sample cutting device, comprising a gang tool, a slot row holddown assembly, a slot row support and collection assembly, a slot row support and collection assembly embedder, a linear motion bearing, an elevating guide rail shaft, and a manual elevating system. Through organic combination of the above assemblies, the device of the invention realizes rapid, efficient and anti-batch mixing effects in fabric sample cutting. And the problems of labor intensive and low efficiency in manual scissor cutting are overcome.

Description

Technical field: [0001] The invention relates to the field of textile testing, especially the testing of formaldehyde content, carcinogenic aromatic amine dyes, heavy metals, pesticide residues and the like of textiles, and is suitable for sample preparation before textile testing. Background technique: [0002] The national standard "GB18401 National Basic Safety Technical Specifications for Textile Products" is a mandatory standard, which stipulates that harmful substances in textiles must be tested, including formaldehyde content, carcinogenic aromatic amine dyes, heavy metals, and pesticide residues. These detection methods require that the size of the sample is not greater than 5mm×5mm, and the textile testing department hopes to have a fast textile fabric cutting device. [0003] At present, the above-mentioned textile fabrics whose size is not larger than 5mm×5mm are all cut by manual scissors, which has low production efficiency and high labor intensity, and does not...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): G01N1/28D06H7/00

Inventor 霍书怀方锡江李璐康司崇泽王秋元

Owner 中纺标检验认证股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com