Achromatic apparatus for achromatizing achromatic toner image formed on recording medium

A technology of toner image and recording medium, applied in the field of decolorization device, which can solve the problem of paper smoke, etc., and achieve the effect of avoiding discoloration and low power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056]

[0057] First, a method for producing a decolorizable toner used in the present invention will be described as Example 1. First, a cyanine-based near-infrared absorbing pigment "IRT" (manufactured by Showa Denko / cf. Figure 17A The structural formula) is 1.5 parts by mass, so that the organoboron compound "P3B" (manufactured by Showa Denko / refer to Figure 17B ) is 4 parts by mass, the polyester binder resin for toner (manufactured by Kao) is 90.5 parts by mass, the negative charge regulator "LR-147" (manufactured by CARLIT, Japan) is 1.5 parts by mass, and Palm WAX1 No. powder (produced by Kato Makoto Co., Ltd.) was 2.5 parts by mass, which were put into a Henschel mixer (manufactured by Mitsui Mining Co., Ltd.) and mixed.

[0058] Then, the above-mentioned mixture was melt-mixed by a twin-shaft stirrer. The thus obtained kneaded material was coarsely crushed by a ROTOPLEX granulator (manufactured by Hosokawa Micron Group) to obtain a coarsely crushed product. Th...

Embodiment 2

[0061]

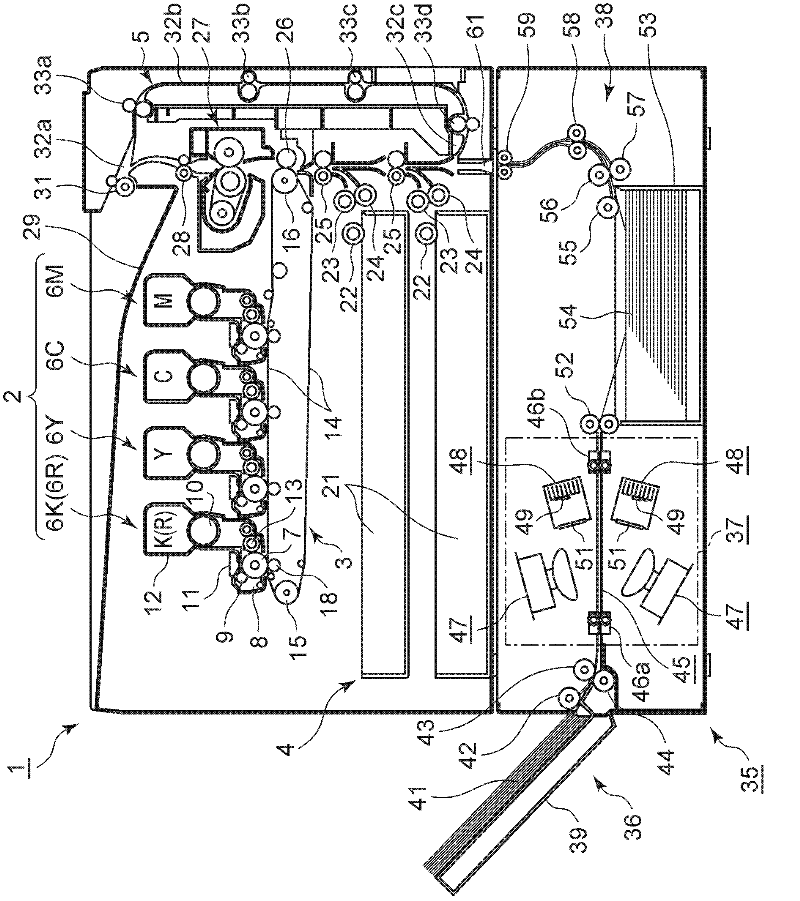

[0062] figure 1 It is a cross-sectional view schematically showing the internal structure of an image forming apparatus with a decolorizing function (hereinafter simply referred to as a printer) provided with decolorizing devices in series according to Embodiment 2 of the present invention. figure 1 The illustrated printer 1 is a tandem color image forming apparatus of an electronic phototype and a secondary transfer method, and an image forming unit 2 is composed of an intermediate transfer belt unit 3 , a paper feeding unit 4 , and a conveyance unit 5 for double-sided printing. .

[0063] The above-mentioned image forming unit 2 is configured by arranging four image forming units 6 (6M, 6C, 6Y, 6K (6R)) in parallel in multiple stages from the right side to the left side in the figure.

[0064]The image forming unit 6R is used for the decolorizable toner R obtained in Example 1, and can be replaced with the image forming unit 6K for the black toner K. The image f...

Embodiment 3

[0174] Figure 13 It is a cross-sectional view showing the structure of the decolorizing unit (decolorizing unit) 150 of the decolorizing device of the third embodiment. In addition, the overall structure of the decolorizing device is the same as figure 1 The structure in the shown decolorizing device 35 is the same, and the basic structure is the same as Figure 4 The decolorizing unit 37 shown is the same. Thus, in Figure 13 in, right with figure 1 , Figure 4 The same structural parts are denoted by the same reference numerals.

[0175] Such as Figure 13 As shown, in the decolorizing unit 150 of the decolorizing device of this embodiment, a large change is applied to the heat radiation heater unit. That is, the heat radiation heater part 151 (151a, 151b) of the decolorizing part 150 of this embodiment is equipped with the 1st heat insulating part 153 first, and this 1st heat insulating part 153 is exposed to the heat from the outside. Figure 4 The portion of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com