Transplanter boat deck assembly

A technology of boat plate and assembly of rice transplanter, which is applied in the direction of transplanting machinery, application, agriculture, etc. It can solve the problems of increasing the resistance of rice transplanter, small buoyancy, and large moving resistance, so as to reduce the friction area, improve the bearing capacity, The effect of reducing the contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

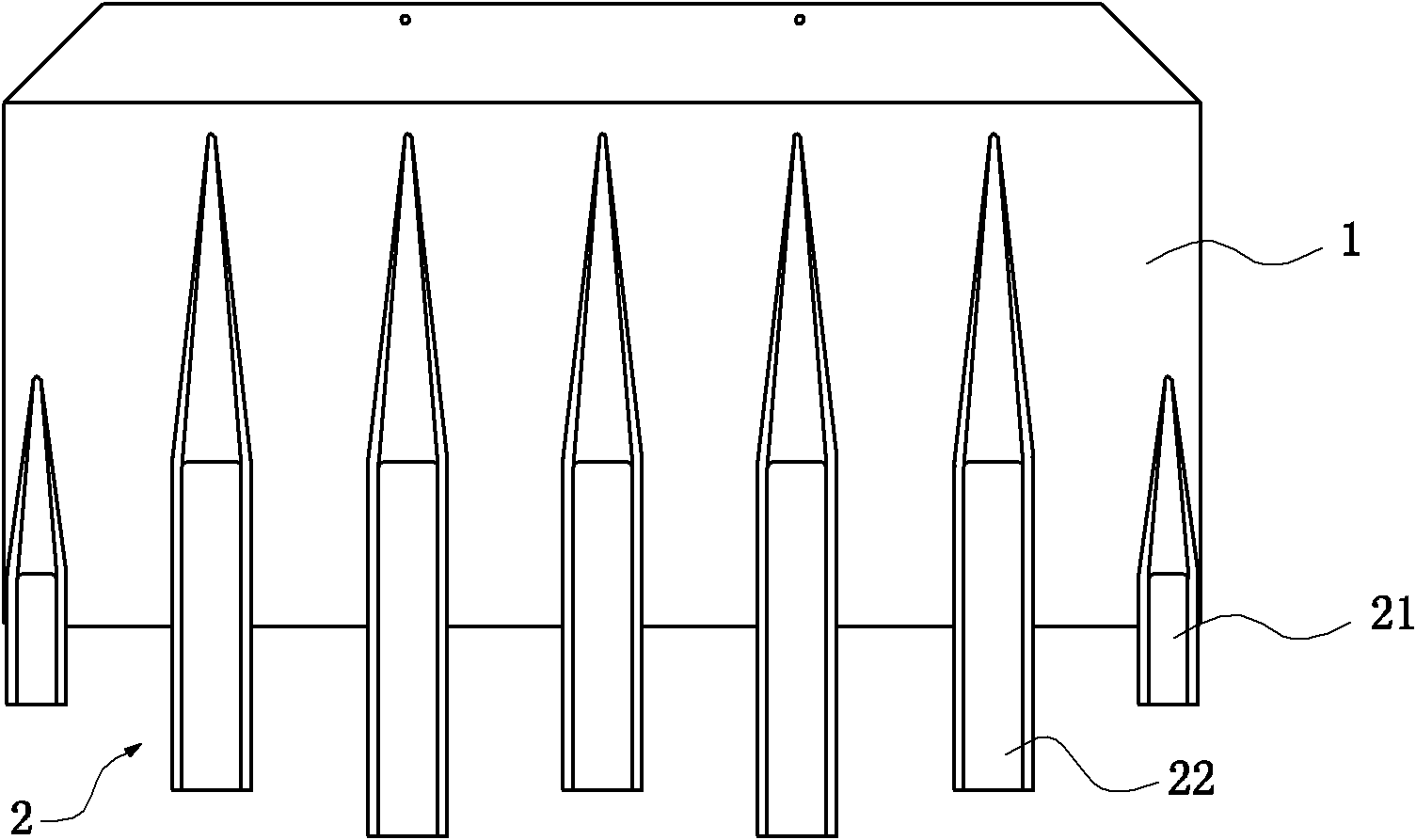

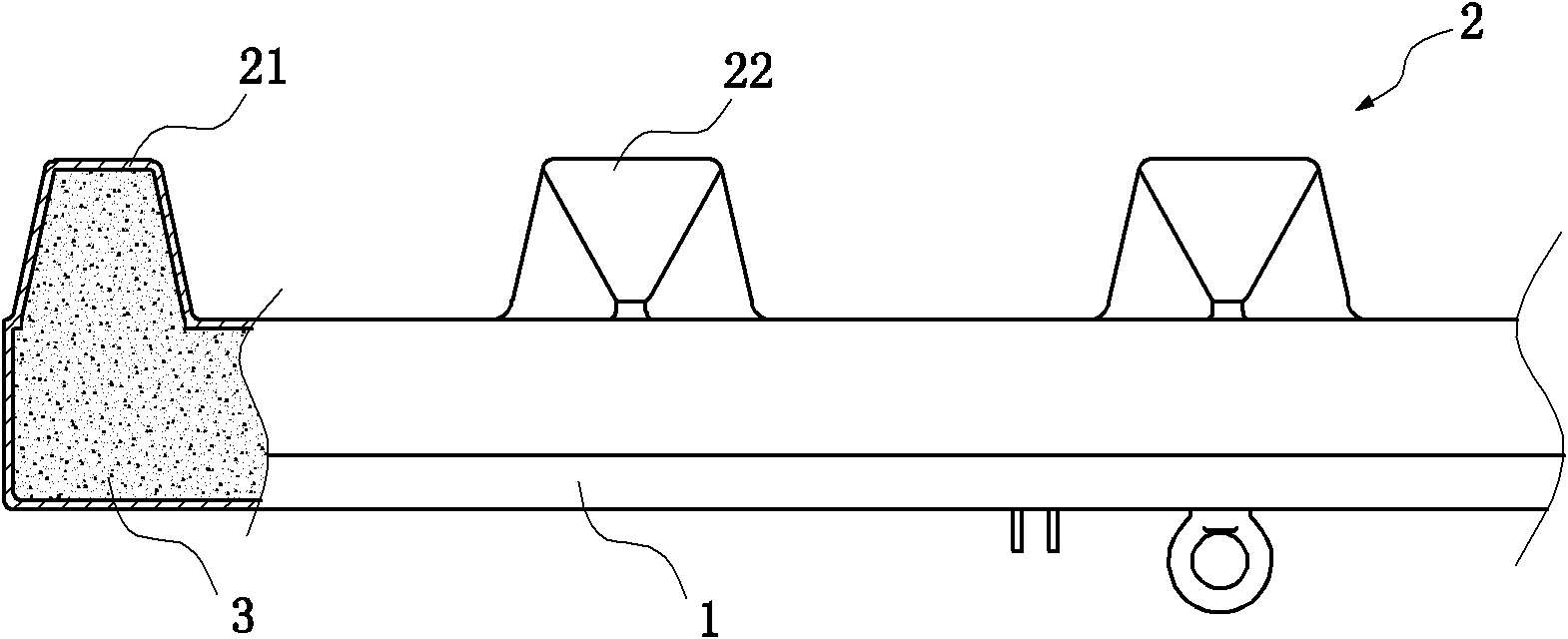

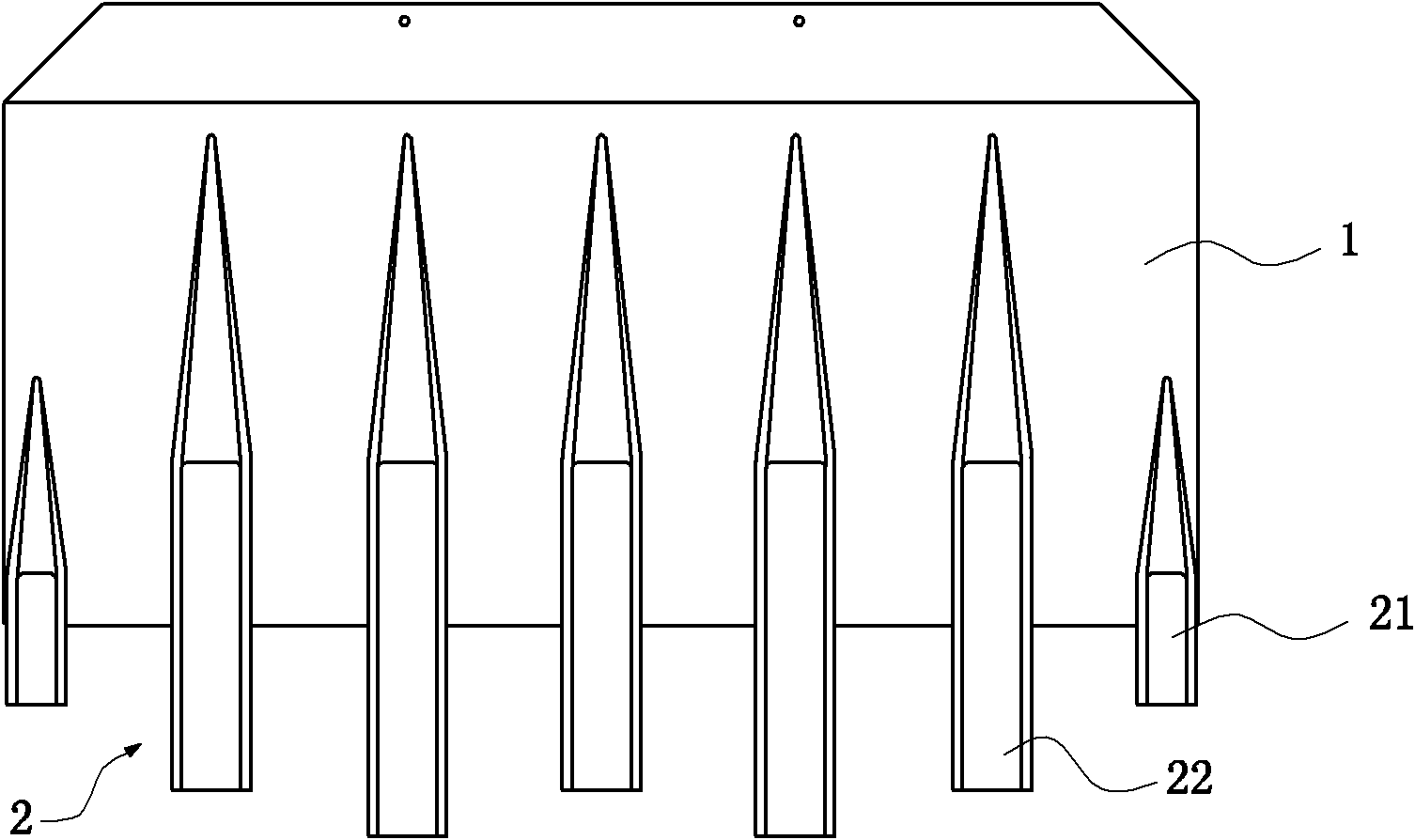

[0029] like figure 1 and figure 2 As shown, the boat deck assembly of the rice transplanter includes a boat deck body 1 and a ridger body 2 located at the bottom of the boat deck body 1 . They are all cavities, and the cavities are filled with lightweight water-blocking material fillers. In this embodiment, the lightweight water-blocking material fillers are polyurethane foam fillers 3. This structure makes the rice transplanter work normally. At this time, the load-bearing work can be completed by relying on the buoyancy generated by the ridging device body 2, which reduces the contact area between the ship deck assembly and the paddy field, reduces the friction area, prevents the ship deck body 1 from dragging the silt, reduces the resistanc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com