Method for pre-treating inverted trough water of electroplating pre-treatment

A pre-treatment and pre-treatment technology for electroplating, applied in metallurgical wastewater treatment, chemical instruments and methods, water/sewage multi-stage treatment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

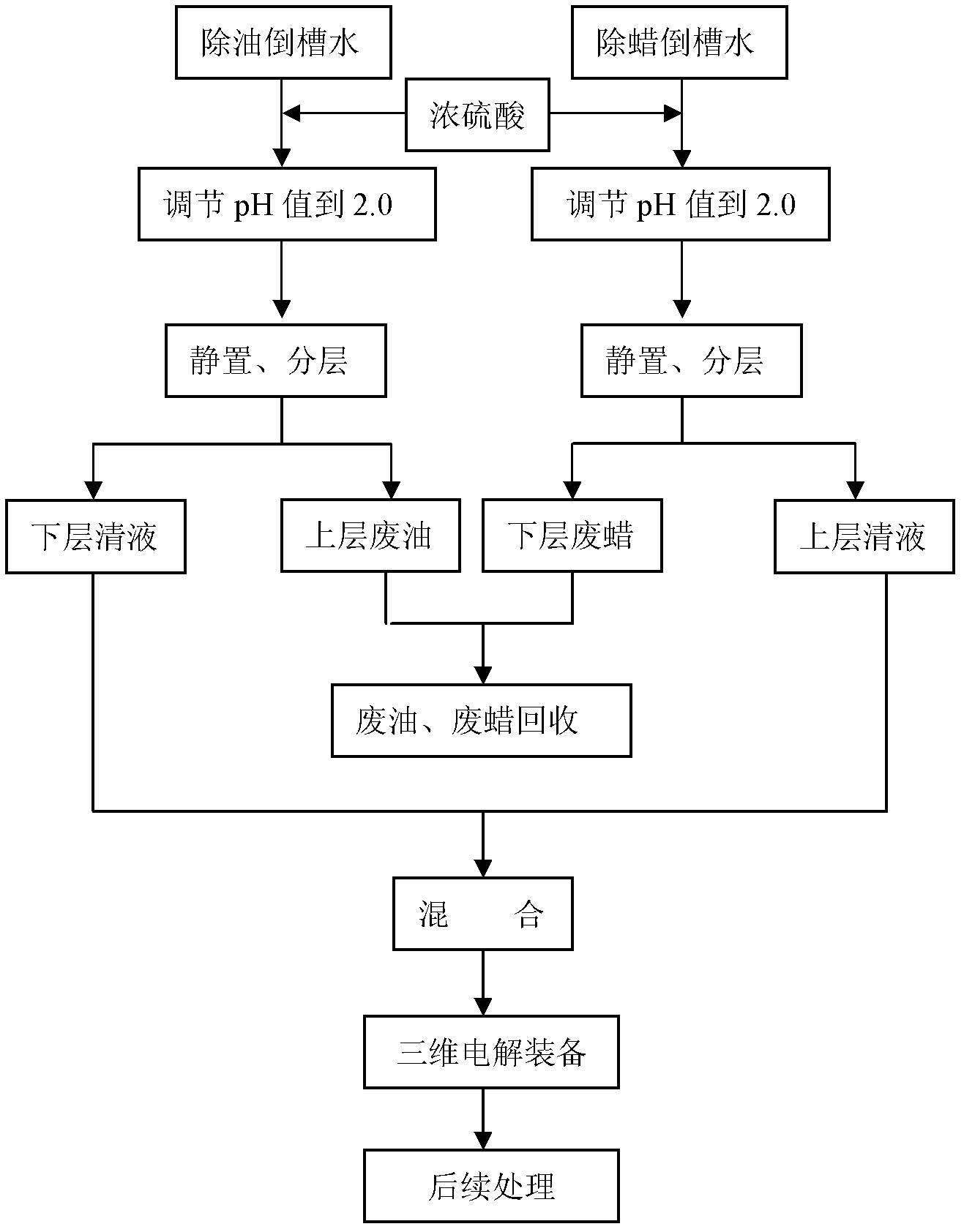

[0018] In this embodiment, the electroplating tank liquid with high organic pollution load and difficult treatment is selected as the processing object, and the acid analysis-three-dimensional electrolysis technology is used to pretreat the tank water. The specific process is called: see figure 1

[0019] (1) Processing object

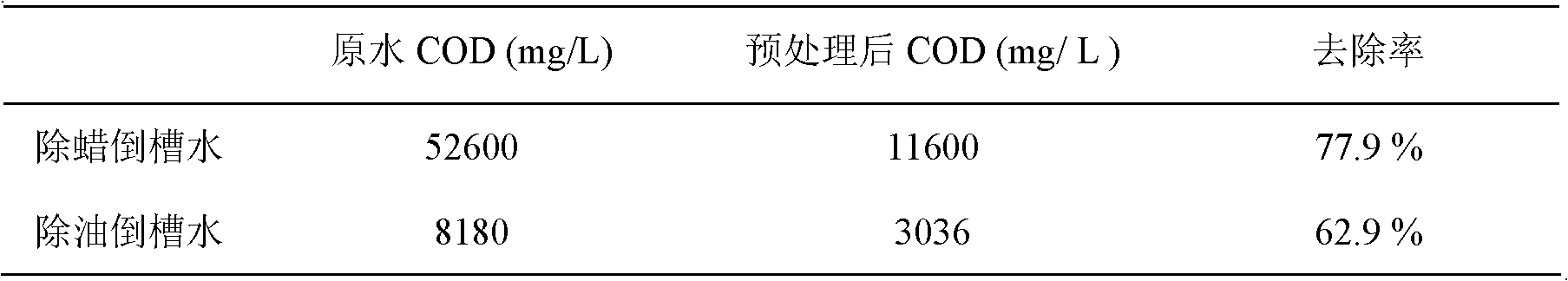

[0020] Degreasing tank water and wax removing tank water of an electroplating factory in Wenzhou, Zhejiang, among which degreasing tank water COD Cr =8180mg / L; COD of wax removal tank water Cr =52600mg / L; the pH value is around 10.

[0021] (2) Process flow

[0022] A: acid analysis process

[0023] Dewaxing and pouring tank water: Take the water sample in a red plastic bucket, add concentrated sulfuric acid while stirring, adjust the pH value to 2.0, stir for 5 minutes, let it stand, take the supernatant liquid, and the waste wax in the lower layer is processed by a professional oil company Recycle.

[0024] Degreasing and pouring tank water: Ta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com