Method and apparatus for depositing film in fiber by using atmospheric pressure glow discharge

A technology of glow discharge and atmospheric pressure, applied in the field of plasma, can solve the problems of difficulty in depositing thin films of optical fibers and high vacuum cost, and achieve the effects of improving transmission efficiency, low equipment cost, and low gas flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with drawings and embodiments.

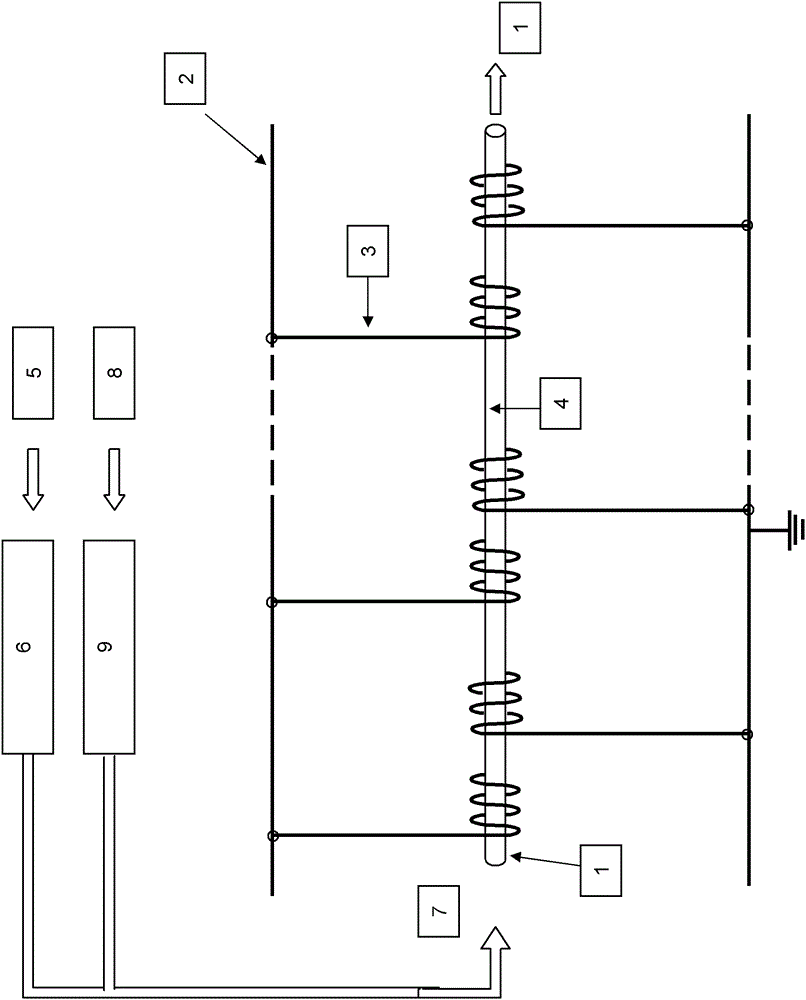

[0023] Devices for depositing thin films in optical fibers using atmospheric pressure glow discharge, such as figure 1 As shown, the discharge plasma chamber, that is, the inside of the optical fiber 1 is under atmospheric pressure conditions. The AC sine wave high-voltage power supply 2 used to generate plasma is connected to the high-voltage electrode 3 , the peak-to-peak voltage reaches over 20KV, and the frequency ranges from 5KHZ to 15KHZ. After high-voltage discharge, plasma 4 is generated in the fiber tube. The distance between the high-voltage electrode and the low-voltage electrode is adjusted between 3 and 5 cm. The optical fiber tube is used as the deposition substrate, and the active material generated by the plasma is deposited on the inner wall of the optical fiber to change the optical density of the optical fiber. Before deposition, use helium 5 as the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com