Large tank rice wine aging system design method

A system design, rice wine technology, applied in the preparation of alcoholic beverages, etc., can solve the problems of high labor intensity, high cost, large wine loss, etc., and achieve the effect of solving the shortage of storage and improving food safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

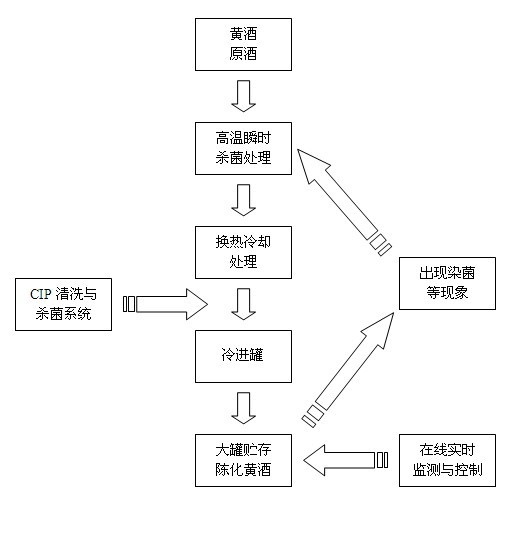

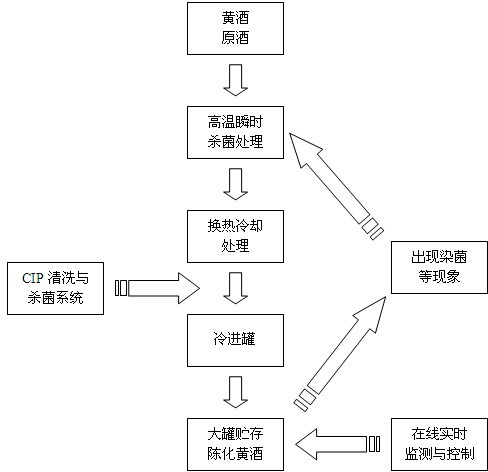

Method used

Image

Examples

Embodiment 1

[0021] The raw rice wine produced in 2009 was sterilized by a tube-plate combined ultra-high temperature instant sterilizer (model: PT-20C-R), and then tested. Embodiment 1 includes the following:

[0022] 1. Sample: rice wine produced in 2009;

[0023] 2. Treatment temperature: 95°C, 121°C, 130°C.

[0024] 3. Processing time: 5 s.

[0025] 4. The results of rice wine sample processing:

[0026] (1) Total sugar:

[0027] After high temperature treatment at 95, 121, and 130°C, the total sugar content in rice wine samples changed little, without great loss. As shown in Table 1.

[0028] Table 1

[0029] Processing temperature / ℃ Total sugar content / (g / L) 95 25.33±0.15 121 25.07±0.06 130 24.62±0.25

[0030] (2) Free amino acids:

[0031] The content of free amino acids does not decrease with the increase of temperature, but also increases at high temperature, so high temperature does not cause a large loss of amino acids in rice wine, and doe...

Embodiment 2

[0039] Utilize the tube-plate combined ultra-high temperature instant sterilizer (model: PT-20C-R) to sterilize the raw rice wine produced in 2009, and then carry out the detection of indicators such as alcohol content, total sugar, pH, amino acid, color, etc. All indicators of rice wine after high-temperature instant sterilization were in line with production requirements. Embodiment 2 includes the following:

[0040] 1. Sample: rice wine produced in 2009;

[0041] 2. Processing temperature: 90°C, 100°C, 110°C, 120°C, 130°C, 140°C;

[0042] 3. Processing time: 5 s;

[0043] 4. The results of rice wine sample processing:

[0044] (1) Alcohol level:

[0045]Table 4

[0046] Processing temperature 90℃ 100℃ 110℃ 120℃ 130℃ 140℃ Alcohol content 18.43±0.57 17.43±1.15 17.10±1.23 18.55±0.69 17.60±1.48 18.87±0.55

[0047] After the data were analyzed significantly, there was no significant difference among the groups. From the perspective of alcoho...

Embodiment 3

[0064] Utilize the tube-plate combined ultra-high temperature instant sterilizer (model: PT-20C-R) to sterilize the raw rice wine produced in 2005, and then carry out the detection of indicators such as alcohol content, total sugar, pH, amino acid, color, etc. All indicators of rice wine after high-temperature instant sterilization were in line with production requirements. Example 3 includes the following:

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com