Method for drying irregular ceramic plates and rods

A drying method and technology of ceramic plates, which are applied in the direction of static material dryers, partial agitation dryers, drying, etc., can solve the problems of restricting the drying of special-shaped ceramic plates and pottery sticks, affecting the surface quality, and rubbing of rollers, etc., so as to reduce Effects of drying and cracking, solving deformation and cracking, and improving pass rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

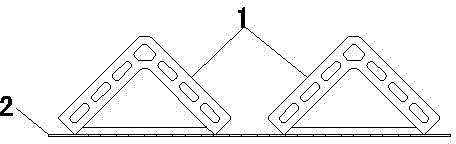

[0018] Embodiment 1: see figure 1 , place the corner ceramic plate 1 with an extruded moisture content of 15wt% (the product specification is 900*150*150mm), place it on the epoxy resin plate 2 with holes in an inverted "V" shape (triangle) according to the figure, and put it into the closed In the box-type drying room, dry for 48 hours according to the temperature, humidity, and time curves in Table 1. During the low-temperature and high-humidity drying period, the initial temperature and high-humidity drying time is 3-3.5 times the subsequent drying time; the high-temperature and high-humidity drying period, the final high temperature The low humidity drying time is 2.5-3.0 times of the previous drying time.

Embodiment 2

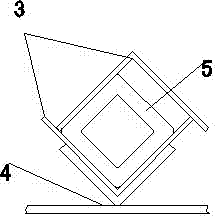

[0019] Example 2: see figure 2 Put the extruded cubic pottery 5 with a moisture content of 15wt% (the product specification is 1500*50*50mm), put it in a movable frame composed of two right-angled aluminum alloys (or stainless steel and other non-rusting metals) 3, and place the whole on Put it on the "v" shaped bracket 4 with plane support, put it into a closed box-type drying room, and dry it for 18 hours according to the temperature, humidity, and time curves in Table 1. 3-3.5 times the drying time; during the high-temperature and high-humidity drying period, the final high-temperature and low-humidity drying time is 2.5-3.0 times the previous drying time.

Embodiment 3

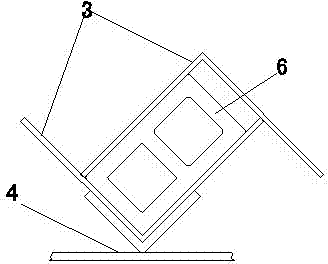

[0020] Embodiment 3: see image 3 Put the extruded shuttle-shaped louver pottery 6 with a moisture content of 15wt% (the product specification is 1200*90*50mm), put it in the movable frame of two right-angled aluminum alloys 3, and put it on the "v" with plane support as a whole. "shaped bracket 4, put it in a closed box-type drying room, and dry it for 30 hours according to the temperature, humidity, and time curves in Table 1. During the low-temperature and high-humidity drying period, the initial temperature and high-humidity drying time is 3-3.5 times the subsequent drying time. times; during the high temperature and high humidity drying period, the final high temperature and low humidity drying time is 2.5-3.0 times the previous drying time.

[0021] See Table 2 for comparison between drying by the method of the present invention and drying in the prior art.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com