Wireless-type transient-strain storage-testing system

A test system and transient technology, applied in signal transmission system, electric/magnetic solid deformation measurement, electromagnetic measurement device, etc., can solve problems such as high requirements for on-site fixation and protection, inconvenient on-site layout, complex system calibration and calibration, etc. , so as to reduce the interference of shock wave and ionization field on the lead wire, the strain data acquisition is convenient, fast and reliable, and the effect of improving the reliability of the test is achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

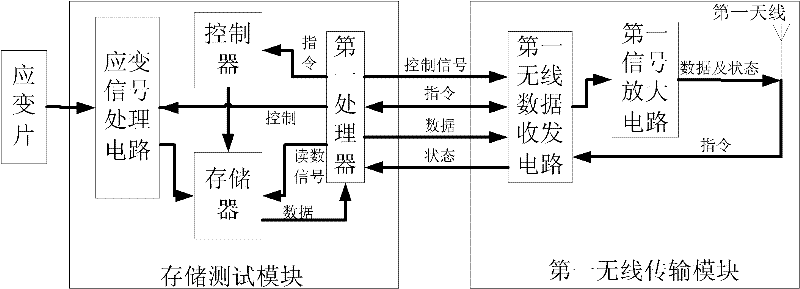

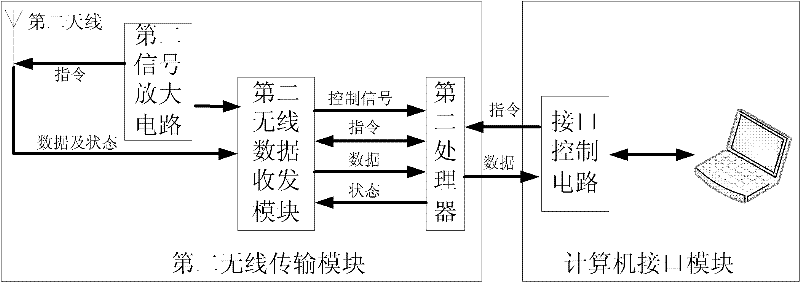

[0029] A wireless transient strain storage test system for field explosion impact test, including control center node and 5 test nodes, such as figure 1 As shown, each test node is composed of a strain gauge, a storage test module and a first wireless transmission module, wherein the storage test module includes a strain signal processing circuit, a controller, a memory and a first processor, and the first wireless transmission module includes a first A wireless data transceiver circuit, a first signal amplifying circuit and a first antenna; such as figure 2 As shown, the control center node is composed of a second wireless transmission module and a computer interface module, wherein the second wireless transmission module includes a second antenna, a second wireless data transceiver circuit and a second processor, and the computer interface module includes an interface control circuit and a computer ;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com