Method for detecting distribution uniformity of colloid in colloid battery

A technology of uniform distribution and colloidal batteries, which is applied in the detection field of colloidal distribution uniformity in colloidal batteries, can solve the problems of many influencing factors, cannot be used as a means of quality monitoring in the production process, and long cycle to achieve high sensitivity and fast detection speed , good reproducibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

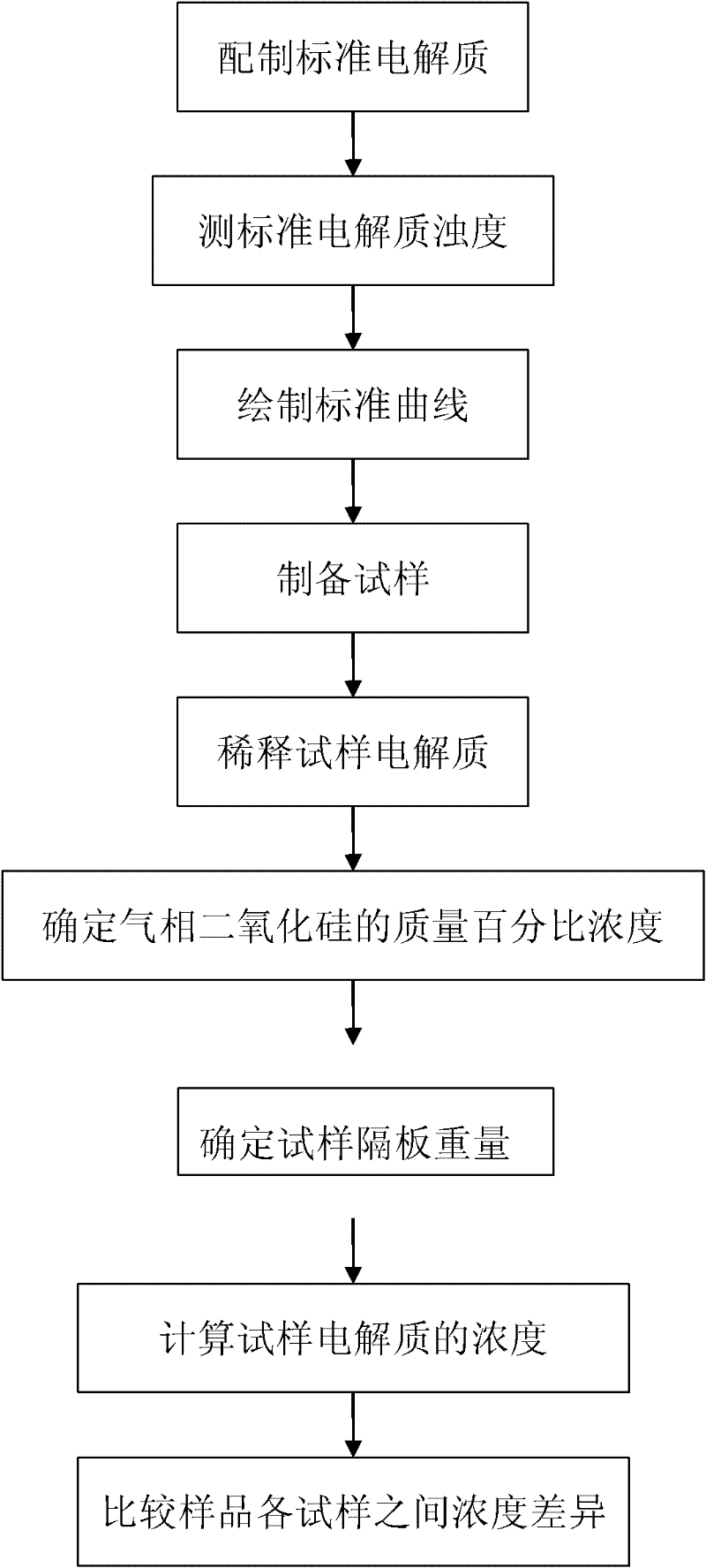

[0022] figure 1 Shown is the detection method of colloidal distribution uniformity in the colloidal battery of the present invention, comprises the following steps:

[0023] A. Prepare standard electrolyte. Prepare a solution with the same liquid composition as the system to be tested, divide it into 20 parts, add fumed silica to it, and prepare the solution with a mass percentage concentration of 0.05%, 0.10%, ..., 1% and a concentration gradient of 0.05%. Standard gel electrolyte.

[0024] B. Measure the standard electrolyte turbidity. Use a turbidimeter to measure the turbidity values of 20 standard electrolytes.

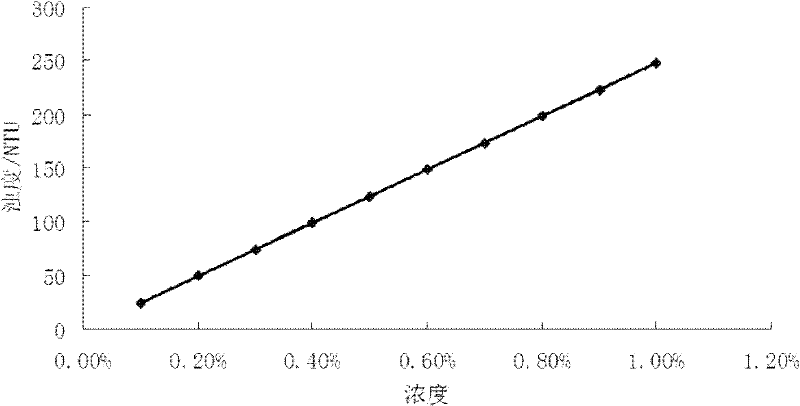

[0025] C. Draw a standard curve. According to the relationship between the turbidity value of the standard electrolyte and its fumed silica concentration, the standard curve of the turbidity changing with the concentrati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com