Laser radar optical system with optical axis calibrating function and optical axis calibrating method

A laser radar and optical system technology, applied in radio wave measurement systems, instruments, etc., can solve the problems of complex operation and external auxiliary devices, and achieve the effects of simple operation, high optical axis calibration accuracy, and convenient use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

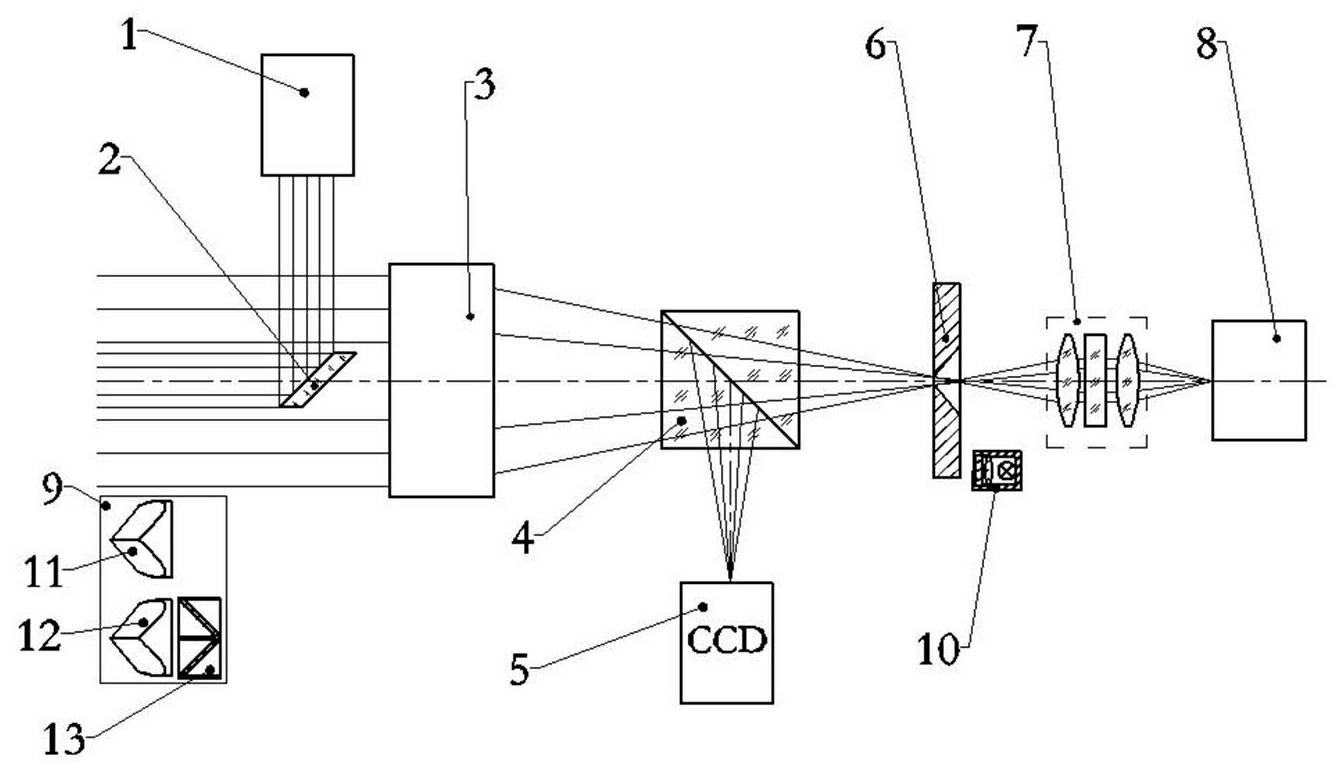

[0026] figure 1 It is a schematic structural diagram of the laser radar optical system with optical axis calibration function of the present invention.

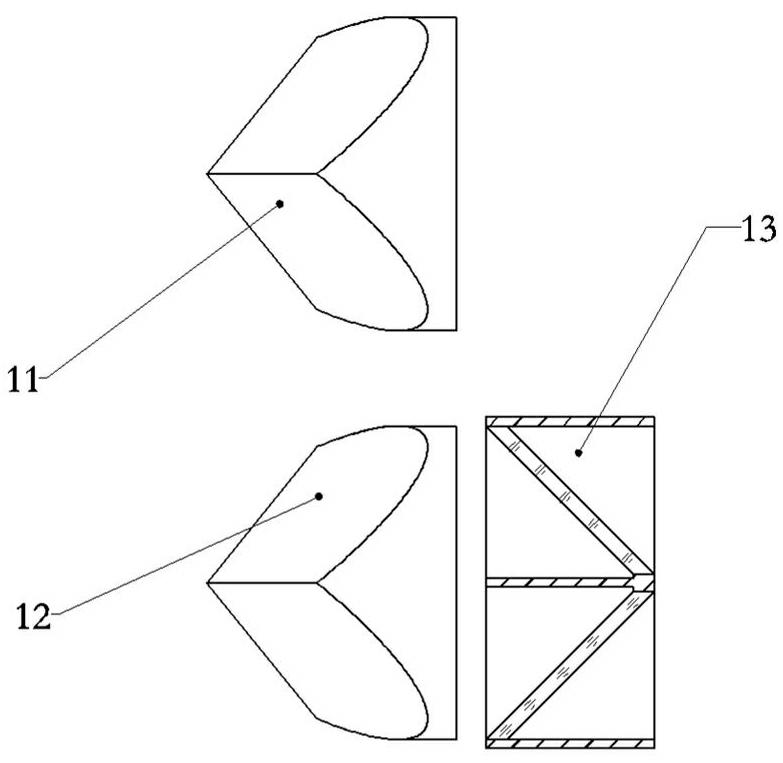

[0027] figure 2 It is a schematic diagram of the structure of the retro-reflecting mirror group in the laser radar optical system with the optical axis calibration function of the present invention.

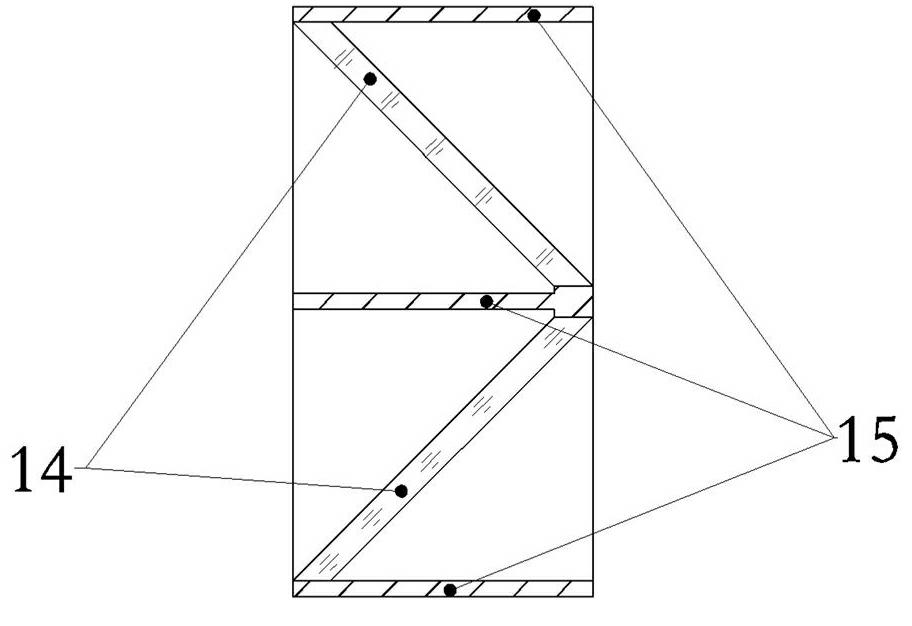

[0028] image 3 It is a schematic structural diagram of the laser attenuator in the laser radar optical system with the optical axis calibration function of the present invention.

[0029] Figure 4 It is a schematic structural diagram of the illumination light source in the laser radar optical system with the optical axis calibration function of the present invention.

[0030] exist Figures 1~4 Among them, the laser radar optical system with optical axis calibration function of the present invention includes a laser 1, a laser emitting mirror 2, a signal receiving optical element 3, a beam splitter 4, a CCD camera 5, a f...

Embodiment 2

[0042] The basic structure of this embodiment is the same as that of Embodiment 1, except that the light absorption plate 15 set in the laser attenuator 13 is made of graphite material.

Embodiment 3

[0044] The basic structure of this embodiment is the same as that of Embodiment 1, the difference is that the light absorption plate 15 set in the laser attenuator 13 is made of ceramic material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com