Stressed liquid crystal transparent projection screen as well as preparation method and application thereof

A projection screen, strained liquid crystal technology, applied in optics, instruments, nonlinear optics, etc., can solve the problem that the shearing effect of polymer dispersed liquid crystal has not been widely developed, and achieve price advantages, energy saving advantages, good imaging effects, and transparency. good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

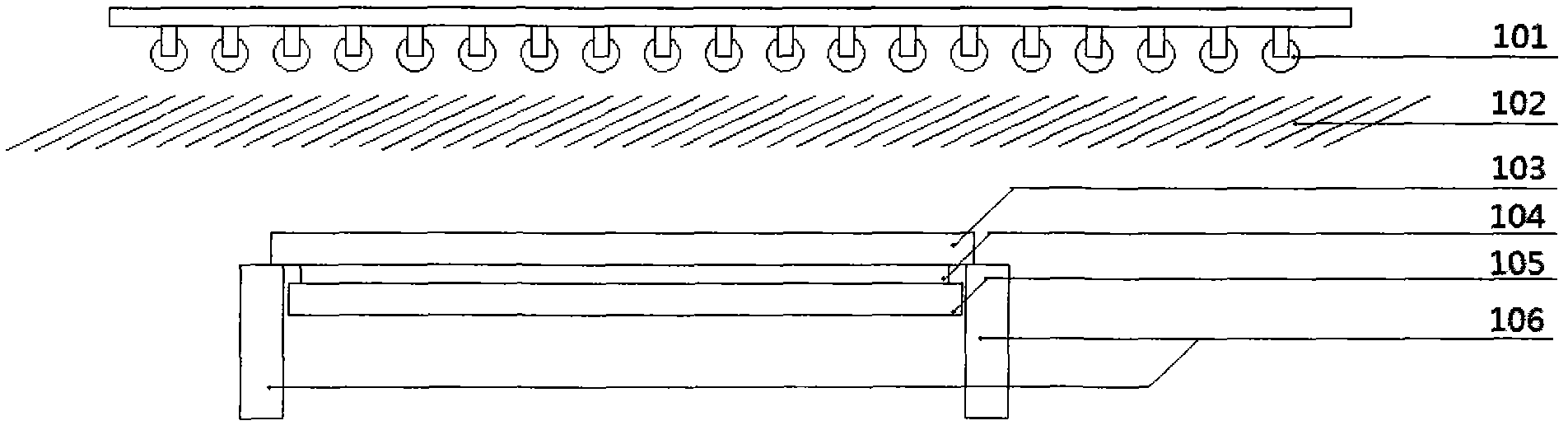

[0029] Example 1, glass substrate strained liquid crystal transparent projection screen

[0030] The first step is to prepare liquid crystal glue

[0031] With 30% epoxy resin DCL3000, 60% polyester acrylate MR100, 4% chain transfer agent and 4% photoinitiator TPO, 2% sulfonium salt is formulated into prepolymer, the prepolymer, nematic The phase liquid crystal material is stirred and mixed evenly at a ratio of 1:1 to prepare a liquid crystal glue mixed material, and the ratios are all percentages by mass;

[0032] The second step is to clean the substrate

[0033] Clean the flat glass substrate in the sink, and wipe the cleaned glass with a clean cloth to ensure that there are no stains and water spots on the glass. The lower glass substrate is 8cm wider than the upper glass substrate;

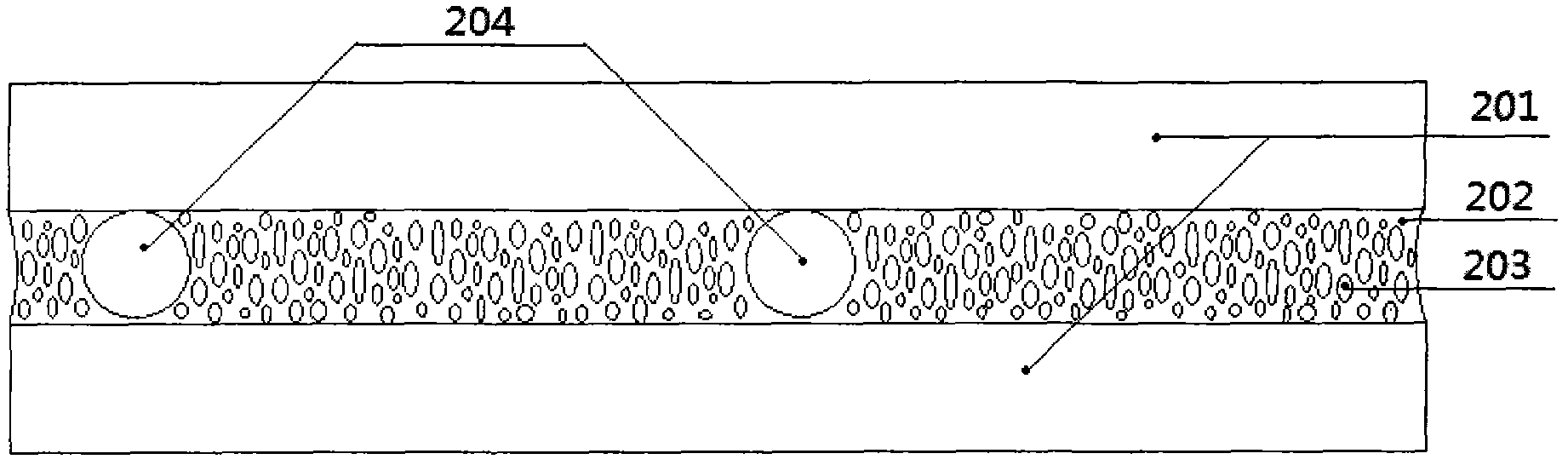

[0034] The third step is to spread the microspheres

[0035] Install a solvent volatile glue (such as butyl acetate) added with plastic microspheres in the sprayer, and spray evenly on a g...

Embodiment 2

[0046] Example 2, acrylic substrate strained liquid crystal transparent projection screen

[0047] The first step is to prepare the liquid crystal glue mixed material

[0048] With 30% epoxy resin DCL3000, 60% polyester acrylate MR100, 4% chain transfer agent and 4% photoinitiator TPO, 2% sulfonium salt is formulated into prepolymer, the prepolymer, nematic The phase liquid crystal material is stirred and mixed evenly at a ratio of 1:1 to prepare a liquid crystal glue mixed solution, and the ratios are all mass percentages;

[0049] The second step is to clean the substrate

[0050] Clean the acrylic substrate in the sink. Wipe the cleaned acrylic substrate with a clean cloth to ensure that there are no stains and water spots on the acrylic substrate. The lower acrylic substrate is 6cm wider than the upper acrylic substrate;

[0051] The third step is to spread the microspheres

[0052] Install a solvent volatile adhesive (such as butyl acetate) with plastic microspheres in...

Embodiment 3

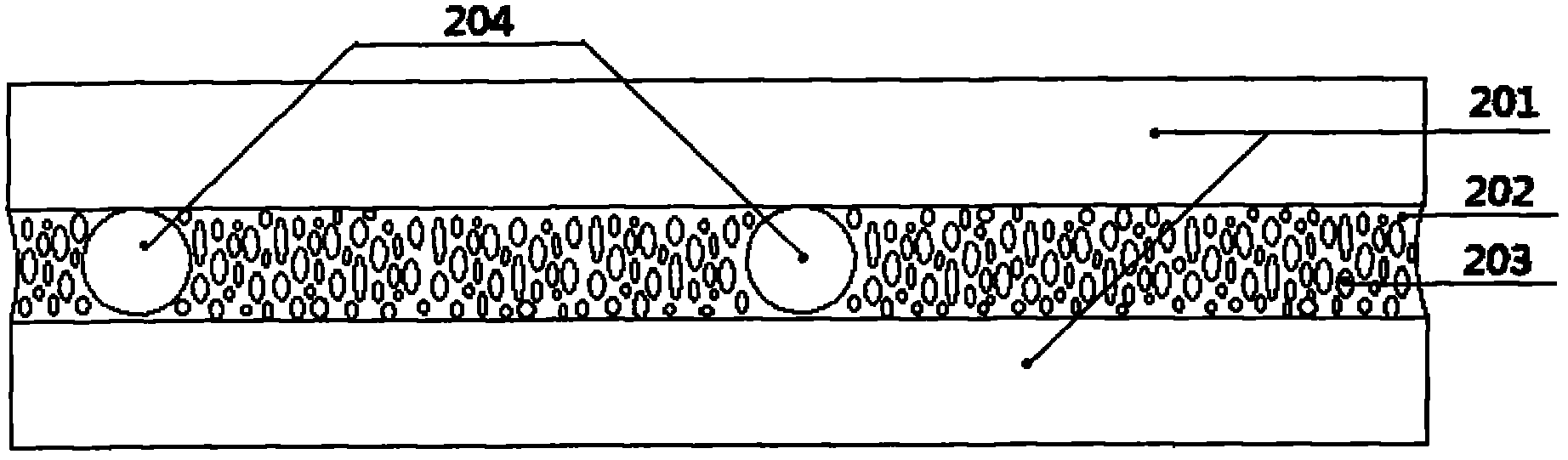

[0062] Cut off the excess part of the wide piece of acrylic to make the upper and lower acrylic substrates neat, and polish the corners of the acrylic. Embodiment 3, film substrate strained liquid crystal transparent projection screen

[0063] The first step is to prepare the liquid crystal glue mixed material

[0064] With 30% epoxy resin DCL3000, 60% polyester acrylate MR100, 4% chain transfer agent and 4% photoinitiator TPO, 2% sulfonium salt is formulated into prepolymer, the prepolymer, nematic The phase liquid crystal material is stirred and mixed evenly in a ratio of 1:1, and is prepared into a liquid crystal glue mixed material, and the percentages are all mass percentages;

[0065] The second step is to clean the substrate

[0066] Clean the film substrate in the sink, and wipe the cleaned film with a clean cloth to ensure that there are no stains and water stains on the film; the upper and lower film substrates have the same size;

[0067] The third step is to spr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com