LTCC (Low Temperature Co-fired Ceramic) lowpass filter

A low-pass filter and parallel technology, applied in the field of electronics, can solve the problems of not finding and reducing the size and area of the device, and achieve the effects of low cost, reduced insertion loss, and good frequency selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

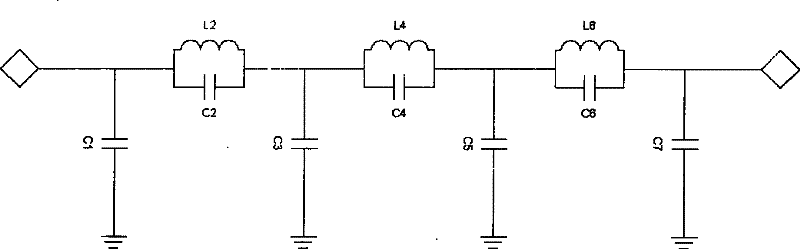

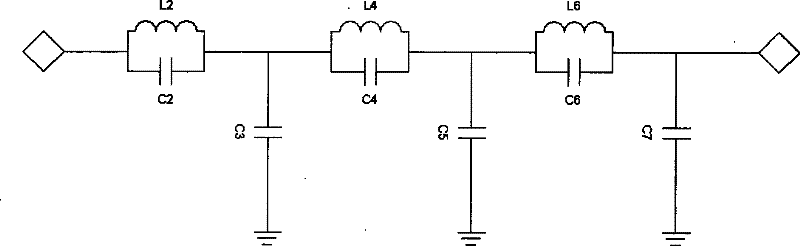

[0029] Such as figure 1 and figure 2 As shown, the present invention is an elliptic low-pass filter with three transmission zeros, which is not removed when the equivalent circuit affected by the packaging structure is not considered figure 1 C1, but if considering the impact of the package structure on this low-pass filter, C1 must be removed to achieve three transmission zeros, and the out-of-band rejection can meet the requirements. The specific connection method has been described in detail in the summary of the invention, and only the specific three-dimensional implementation method is described here as follows:

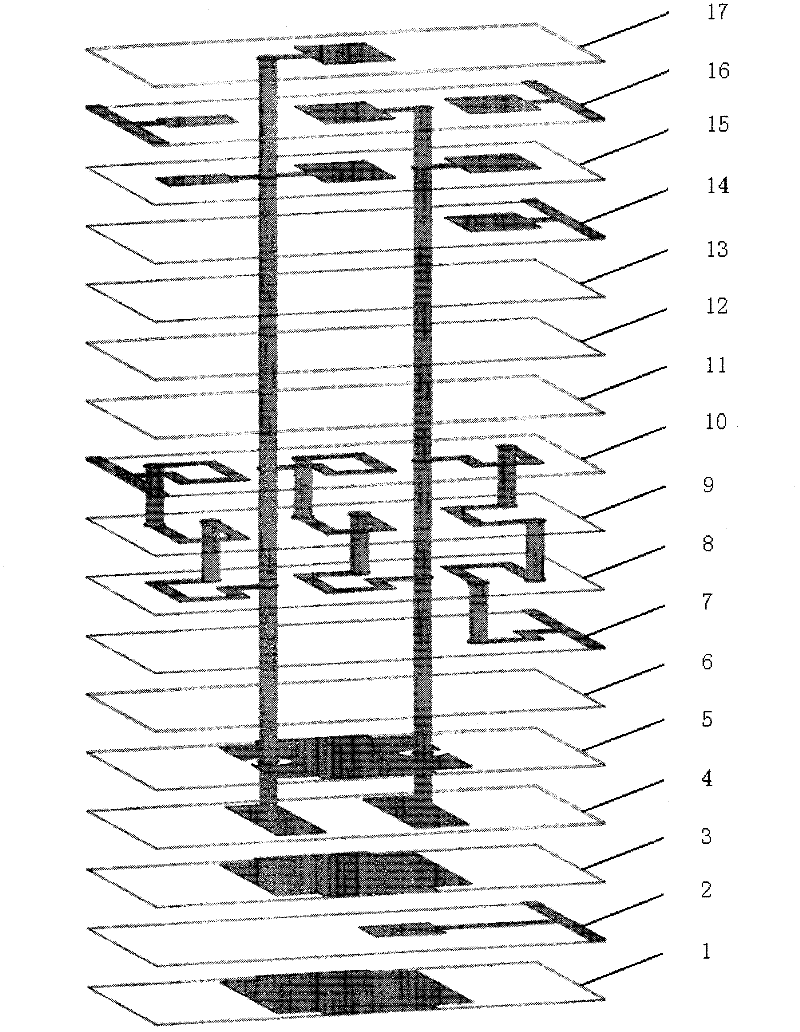

[0030] Such as image 3 as shown, image 3 A total of 17 layers are drawn in the middle, and the bottom and top packaging layers are not drawn, and in order to facilitate the description of the connection relationship, the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com