Ultrasonic vacuum energy-saving cleaning machine

A technology of ultrasonic waves and cleaning machines, applied in cleaning methods and appliances, cleaning methods using liquids, chemical instruments and methods, etc., can solve the problems of affecting the heat treatment quality of the workpiece surface, reducing the cleaning effect of the workpiece surface, and cannot be cleaned, etc., to achieve Cleaning time is shortened, work efficiency is improved, and energy consumption is saved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

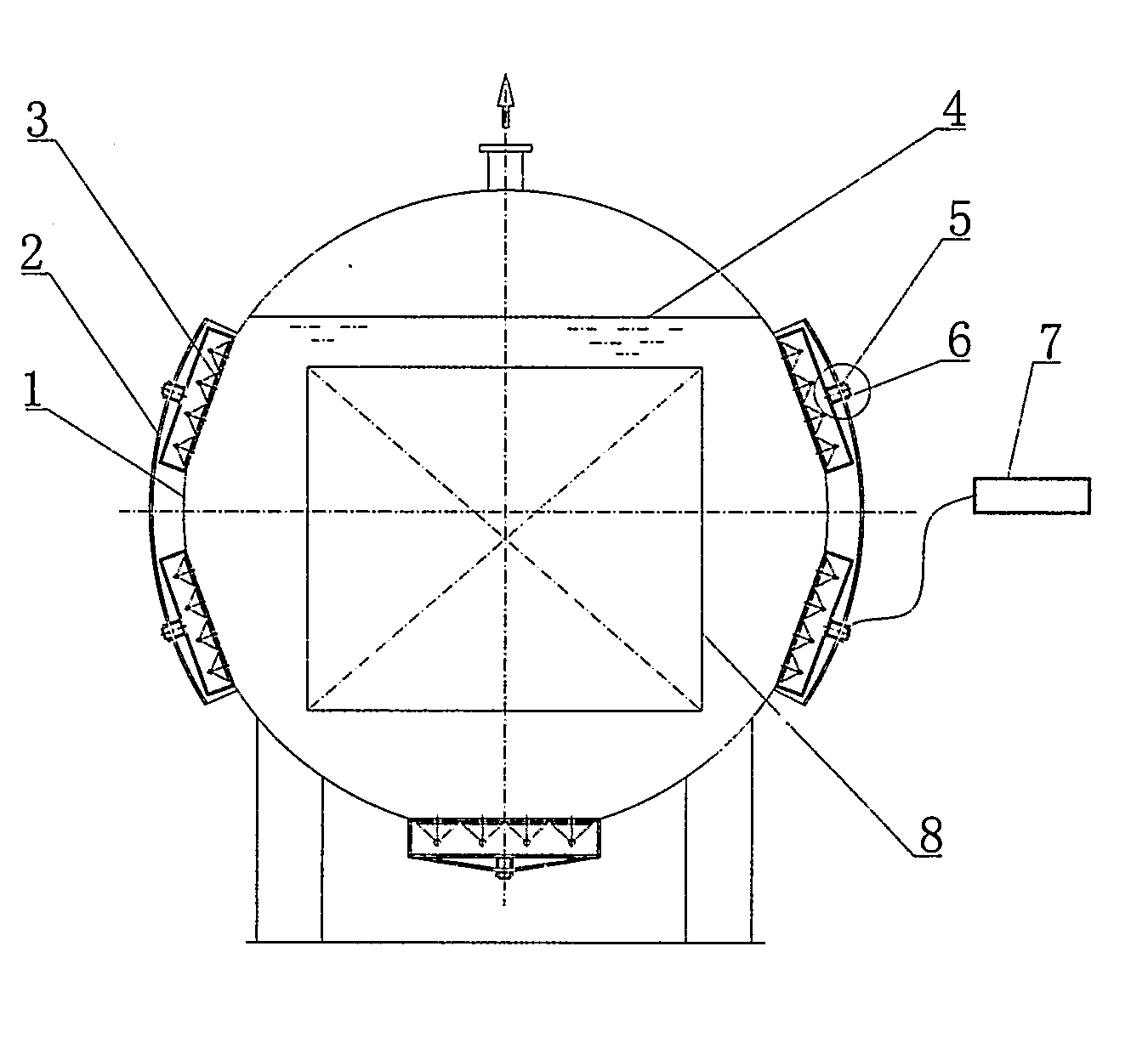

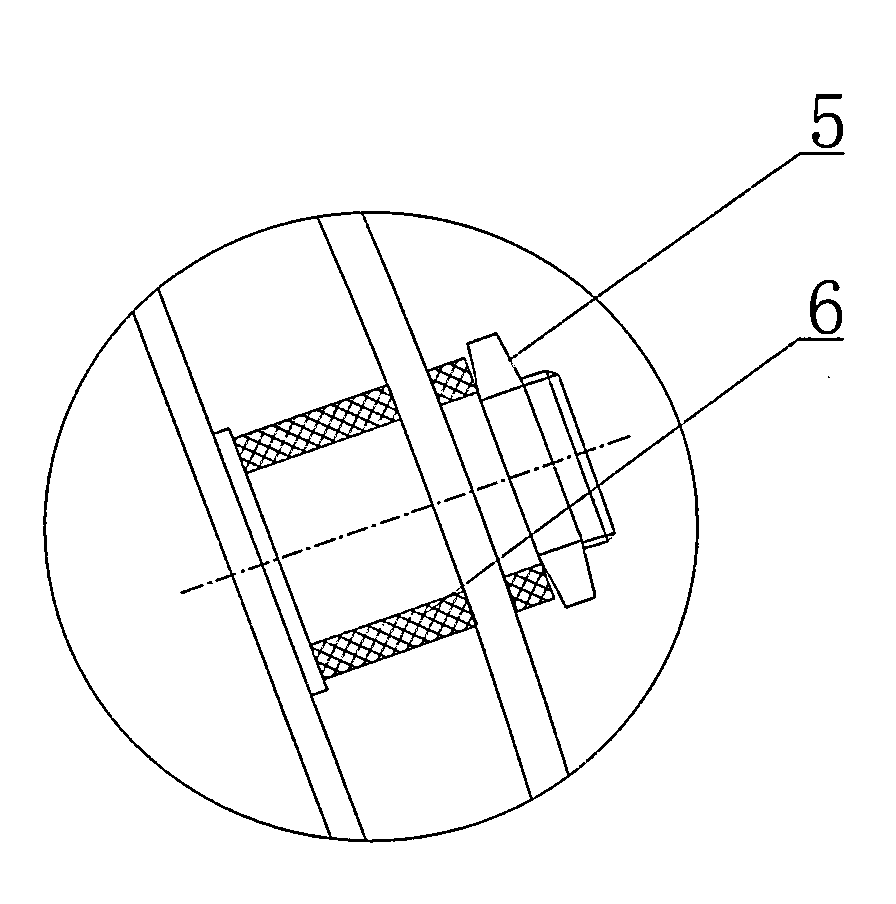

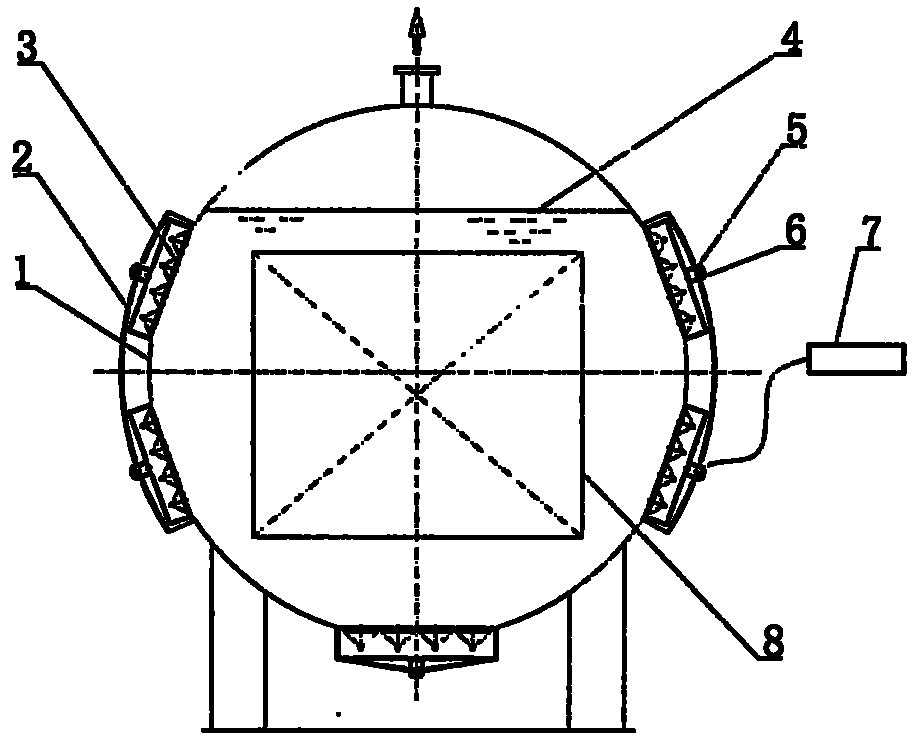

[0009] combine figure 1 , figure 2 , a plurality of grooves 2 are arranged on the periphery of the vacuum chamber 1, and the ultrasonic vibrating plate 3 is evenly installed in the inner groove 2 below the liquid level of the water-based cleaning solvent 4, and the connection with the locking nut 5 and the sealing gasket 6 is realized. The connection and sealing of the vacuum chamber 1, the control line of the ultrasonic generator 7 is connected with the ultrasonic vibration plate 3, the ultrasonic generator 7 works to generate high-frequency signals and transmits them to the ultrasonic vibration plate 3, and the ultrasonic vibration plate 3 converts the high-frequency signals into ultrasonic waves , the ultrasonic waves generate a large number of high-pressure bubbles in the water-based cleaning solvent 4, and move toward the workpiece direction. After the high-pressure bubbles touch the surface of the workpiece 8, they are continuously washed away to peel off the dirt. In ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com