Device and method for one-step multi-directional composite forming of middle flange pipe joint of round bar material

A composite forming, round bar technology, applied in forging/pressing/hammer devices, mechanical equipment, engine components, etc., can solve the problems of different plastic processing processes, low material utilization, and difficult forming, and save processing time. , High material utilization rate, material saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

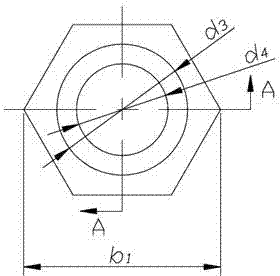

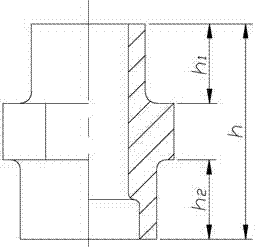

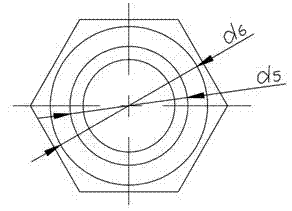

[0037] Example: A typical middle flange pipe joint, small end outer diameter d 3 =20mm, height h 1 =14mm, the outer diameter of the big end d 6 =24mm, height h 2 =14mm, through hole diameter d 4 =12mm, the diameter of the stepped hole at the big end d 5 =17.8mm, the central hexagonal flange is simplified into a cylindrical flange with a diameter of 30mm, the total height of the central flange pipe joint h =38mm; material is 15#; round bar diameter is used d 1 =24mm, l =26.5mm; Put the round bar on the die core 4, install the punch 2 in the upper pit 5 of the punch upsetting ring, and place it on the round bar, from top to top on a 1600KN hydraulic press Extrusion is performed under the pressure, the metal filling condition is good, and the metal flow condition is consistent with the design.

[0038] The one-step multi-directional composite forming of the middle flange pipe joint method of the present invention can make the metal flow up, down and radially in multiple directions at ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com