Device and method for forming central flange pipe joint from round rod material in one-step, multidirectional and composite manner

A compound forming and round bar technology, applied in forging/pressing/hammer devices, mechanical equipment, engine components, etc., can solve the problems of different plastic processing techniques, low material utilization rate, low production efficiency, etc., to save processing time , high utilization rate of materials, less process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

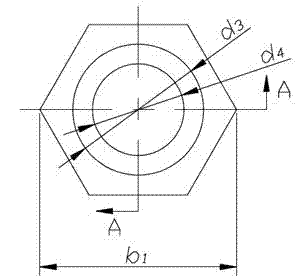

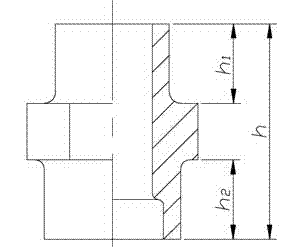

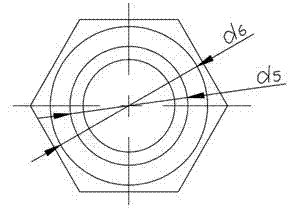

[0037] Example: A Typical Mid-Flanged Fitting, Small End OD d 3 =20mm, height h 1 =14mm, outer diameter of big end d 6 =24mm, height h 2 =14mm, through hole diameter d 4 =12mm, big end step hole diameter d 5 =17.8mm, the hexagonal flange in the middle is simplified into a cylindrical flange with a diameter of 30mm, and the overall height of the pipe joint in the middle flange h =38mm; the material is 15#; the diameter of the round bar is used d 1 =24mm, l =26.5mm; place the round bar on the core 4 of the die, install the punch 2 in the upper pit 5 of the upsetting ring of the punch, place it on the round bar, and put it on the 1600KN hydraulic press from top to bottom The extrusion is carried out under the pressure, the metal filling is in good condition, and the metal flow is consistent with the design.

[0038] The one-step multi-directional compound forming method of the middle flange pipe joint of the round bar material of the present invention can make the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com