Automatic laser scanning positioning steel grating numerically-controlled cutter

An automatic positioning and laser scanning technology, applied in welding equipment, gas flame welding equipment, metal processing equipment, etc., can solve the problems of inability to achieve normal cutting, low workpiece size accuracy, and inability to cut, etc., to achieve flexible and simple manual intervention, The effect of accurate size, free from manual lofting and manual cutting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

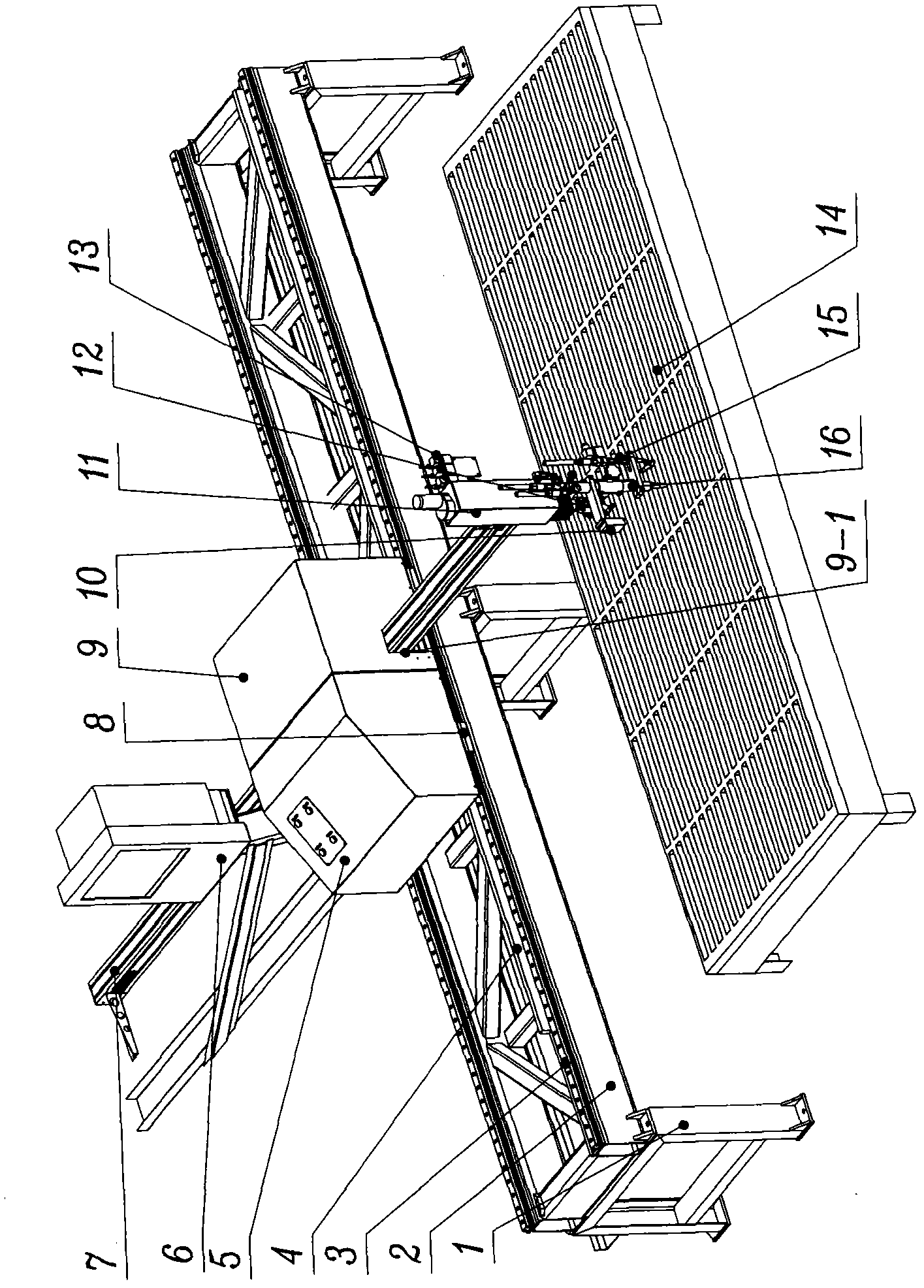

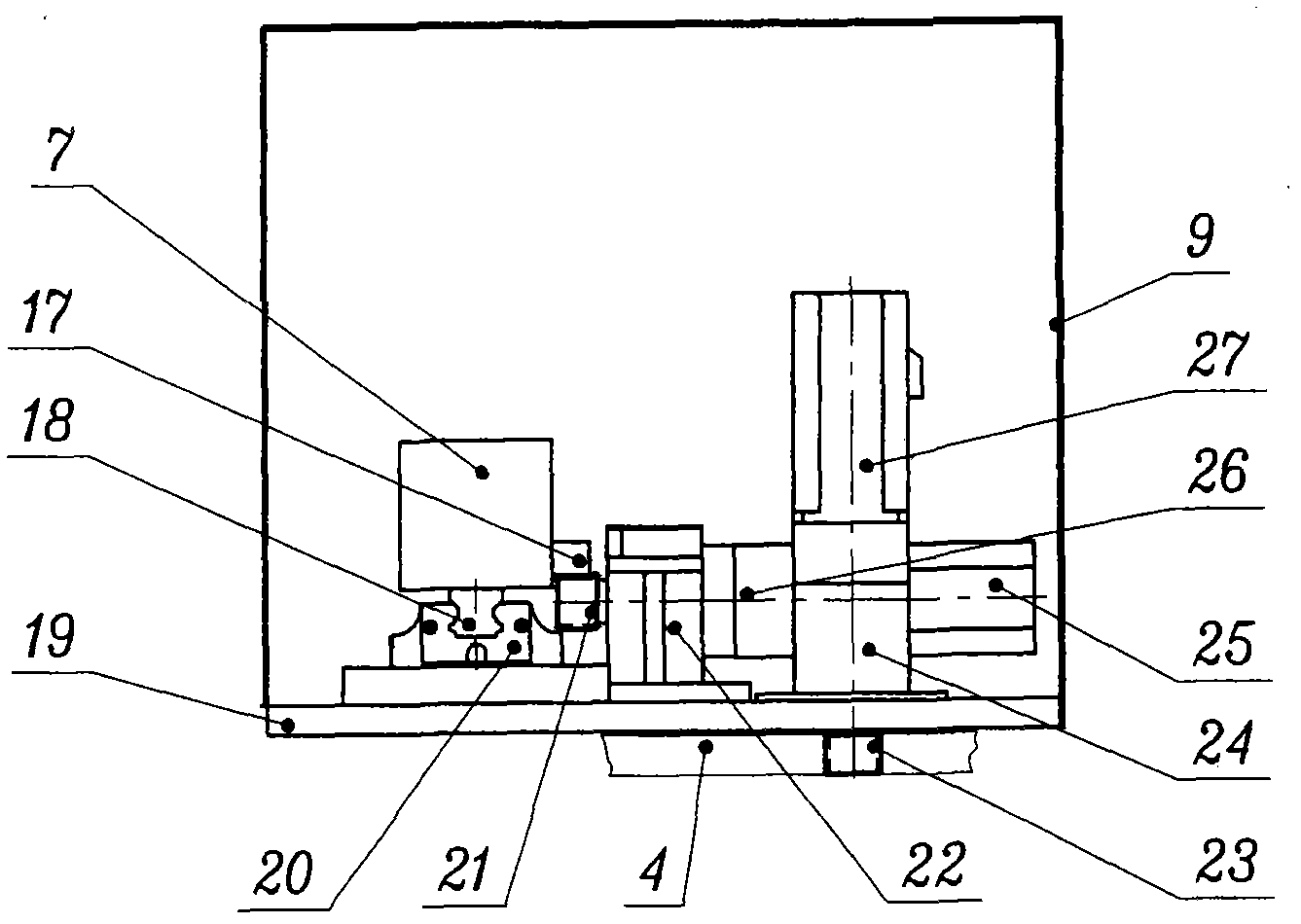

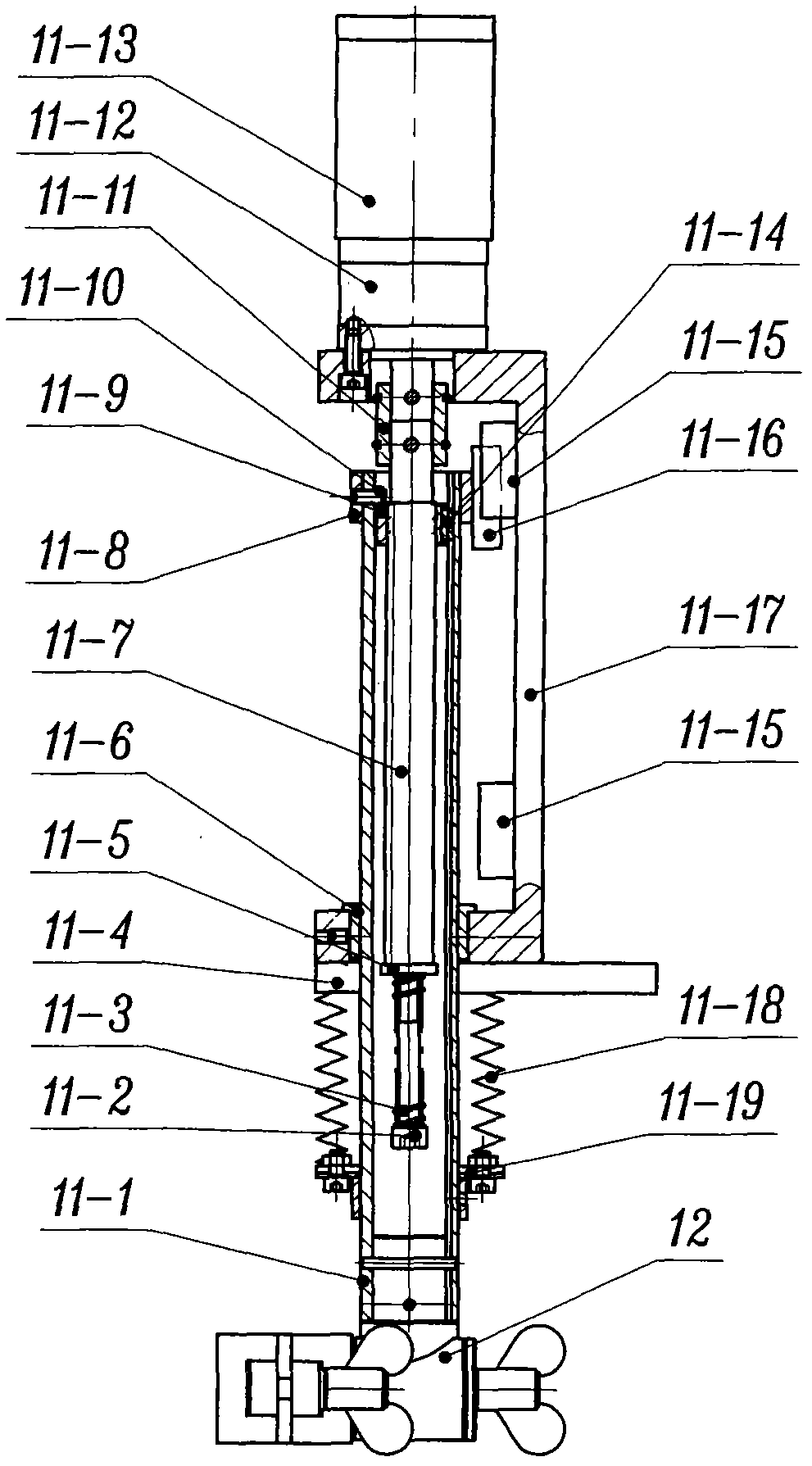

[0037] Depend on figure 1 , figure 2 , image 3It can be seen that the laser scanning automatic positioning steel grating numerical control cutting machine of the present invention includes a CNC numerical control system 6, a laser scanner 10, electrical components 5, a driving mechanism, a flame cutting torch 16 and an automatic ignition device 15; wherein:

[0038] (1) CNC numerical control system: refer to figure 1 , Figure 5 .

[0039] Such as figure 1 As shown, the CNC numerical control system 6 is a device for realizing digital control, which can perform precise calculations on scanning positions and cutting process steps. The function of CNC numerical control system is to realize the automatic control of automatic positioning, preheating, cutting and other process steps through the collection of cutting position, machin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com