Dry mixed mortar stirring coating machine

A technology for dry-mixed mortar and spraying machine, which is applied to cement mixing devices, ceramic molding machines, clay preparation devices, etc., can solve the problems of troublesome cleaning, labor-intensive, low efficiency, etc., achieves convenient construction and handling, and improves use efficiency. , Improve the effect of worker arrangement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

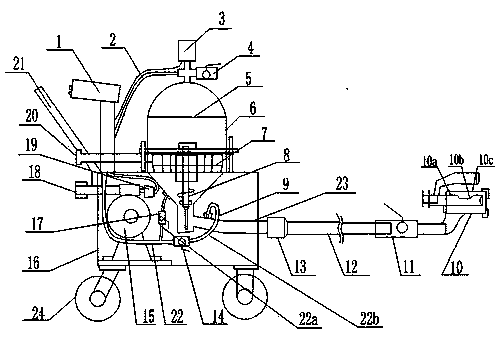

[0022] Below in conjunction with accompanying drawing, the present invention will be further described:

[0023] Such as figure 1 As described above, a dry-mixed mortar mixing and spraying machine is used in conjunction with an anti-segregation mortar bin and a dry-mixed mortar pneumatic conveying bin pump. It includes a trolley 16 and a mixing tank 6 fixed on the trolley 16, a water pump 15 and a general controller 1. The master controller 1 is also used to control the amount of feed, water intake and water pressure balance. In order to facilitate the work, movable wheels 24 are provided at the bottom of the trolley 16, and handrails 21 are provided on the side of the trolley 16.

[0024] The middle part of the stirring tank 6 is equipped with an impeller 7 and a stirring shaft 8 socketed with the impeller 7. A filter 5 is provided above the impeller 7 to prevent dust from entering the top of the stirring tank 6. The top of the stirring shaft 8 is sleeved on the impeller 7. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com