Multifunctional jacquard double-sided seamless integral molding machine

A multi-functional, forming machine technology, applied in the field of knitting machinery, can solve the problems of high machine running resistance, failure to change the thread by track, and poor reliability, so as to reduce the running resistance of the machine, improve the stability of the needle movement, and change the thread speed fast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

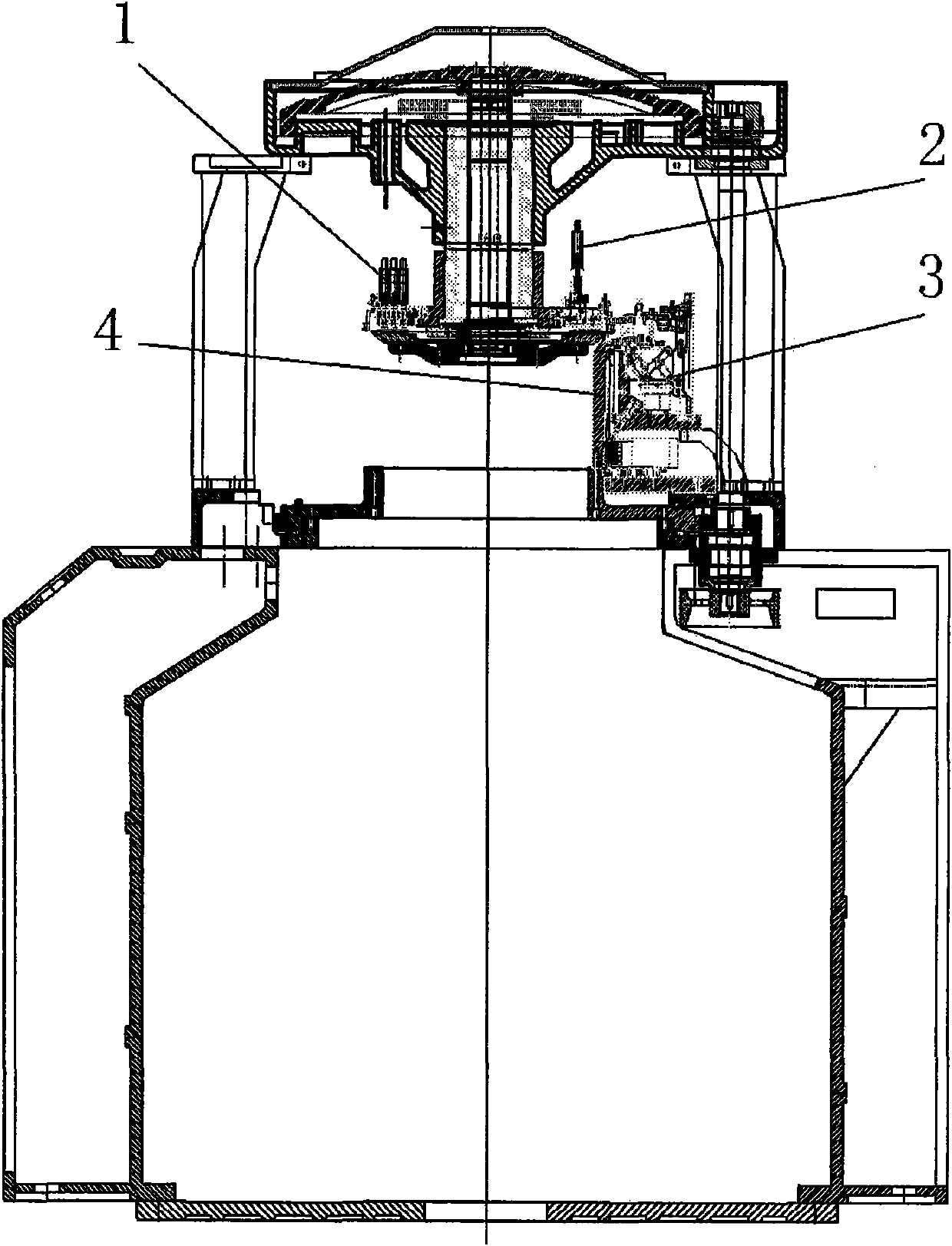

[0037] Example: see Figures 1 to 5 As shown, the multifunctional jacquard double-sided seamless integrated molding machine includes a combined triangle mechanism 1, a density control device 2, a thread adjustment mechanism 3 and a needle selection device 4,

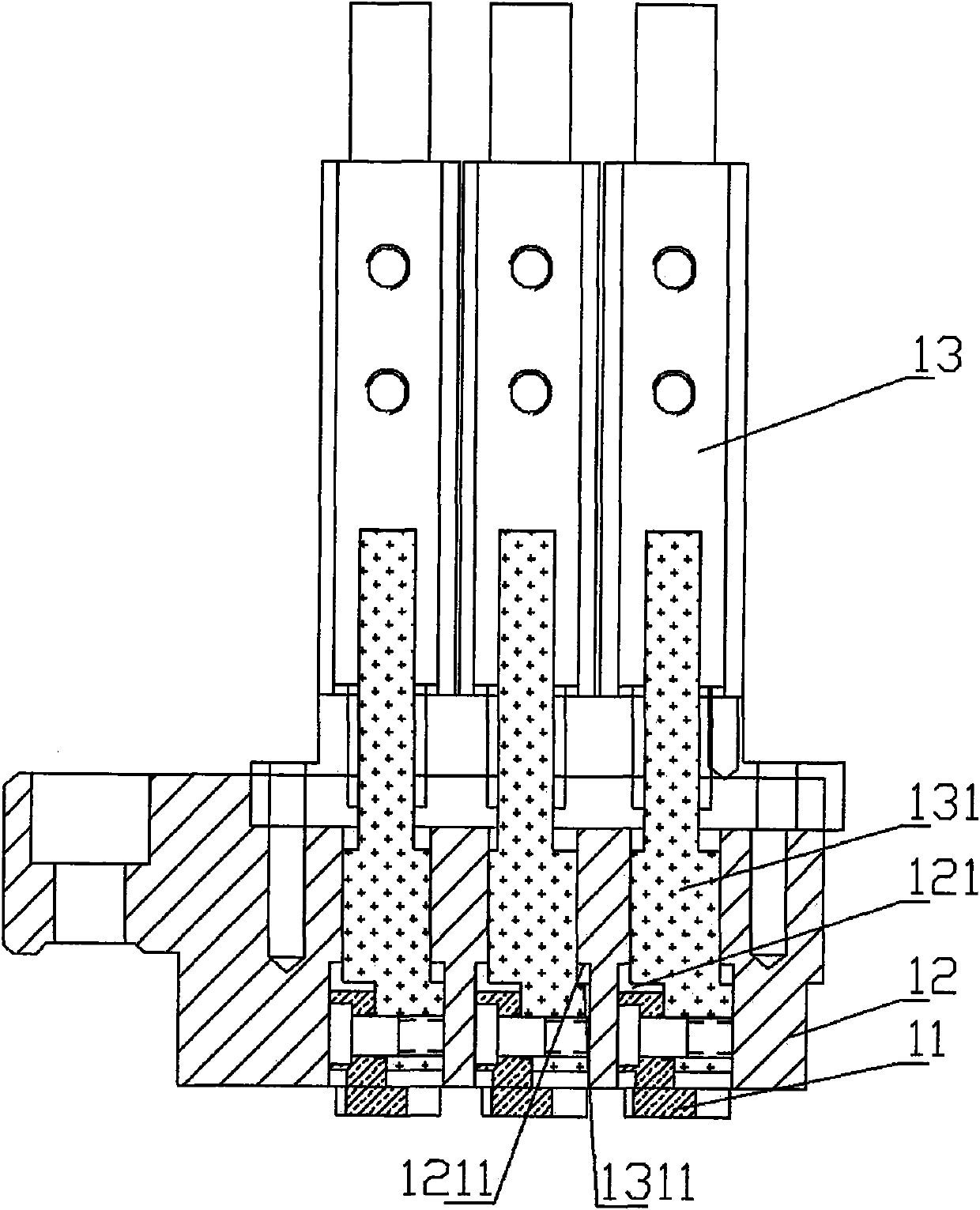

[0038] The structure of its triangular mechanism 1 is that a triangular seat through hole 121 is formed on the triangular seat 12, and a through hole step 1211 is formed in the triangular seat through hole 121, and the piston 131 of the triangular mechanism cylinder 13 is inserted and sleeved in the triangular seat through hole 121. , the piston 131 is formed with a piston step 1311, the piston step 1311 is limited to the through hole step 1211, the triangular block 11 is fixed on the piston 131, and the triangular mechanism cylinder 13 is fixed on the triangular seat 12;

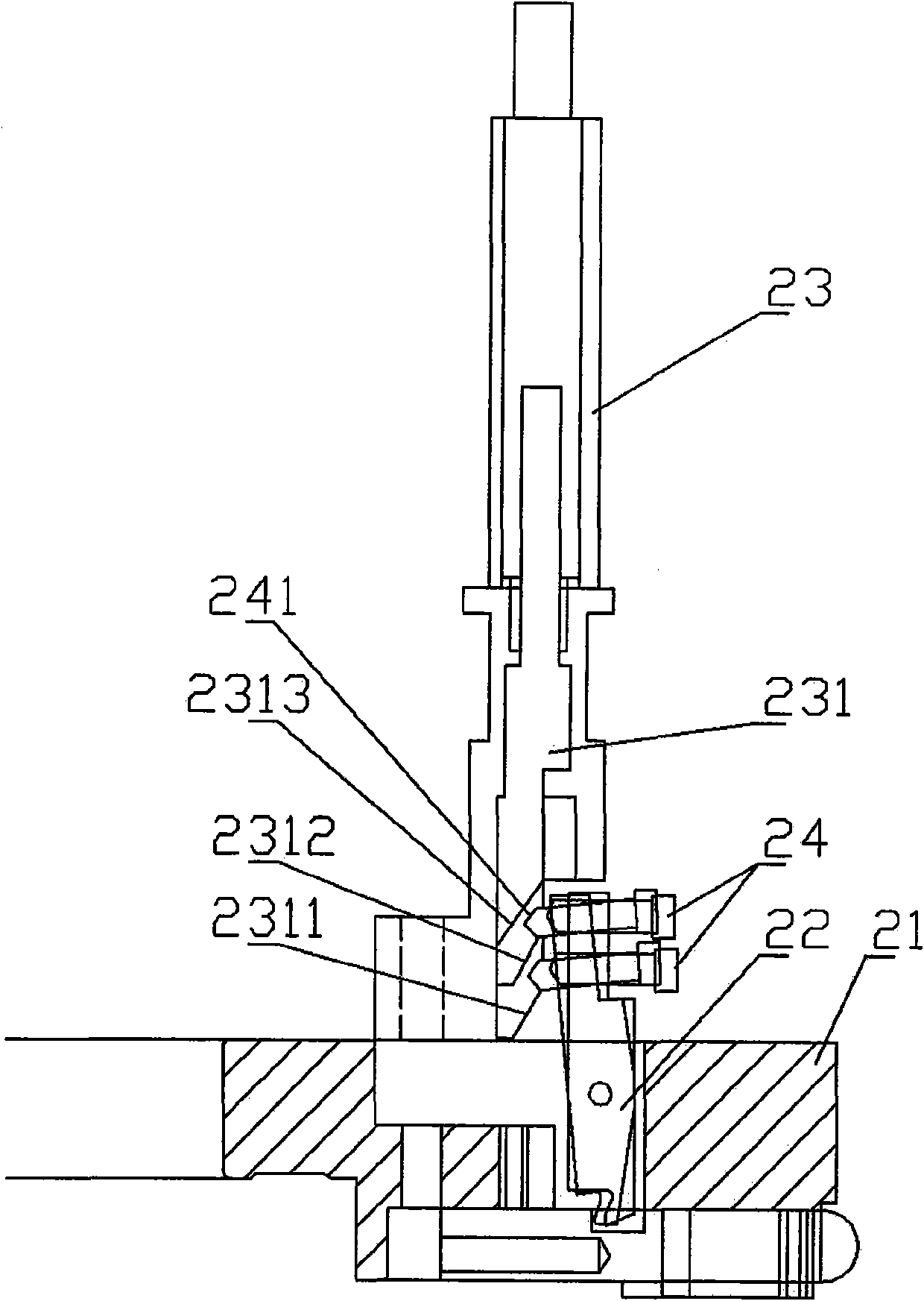

[0039] The structure of its density control device 2 is that a density control cylinder 23 is fixed on the knitting seat 21, and the piston 231 of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com