Engineering structure for improving water and sediment conditions of lock chamber of lock multi-section dispersive water conveyance system

A technology of decentralized water delivery and engineering structure, applied in ship locks, ship lifting devices, river regulation, etc., can solve problems such as reducing the minimum navigable water depth of lock chambers, increasing maintenance workload, and affecting ship navigation, etc., to reduce operation and maintenance Cost, convenient construction and maintenance, and the effect of saving operation and maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

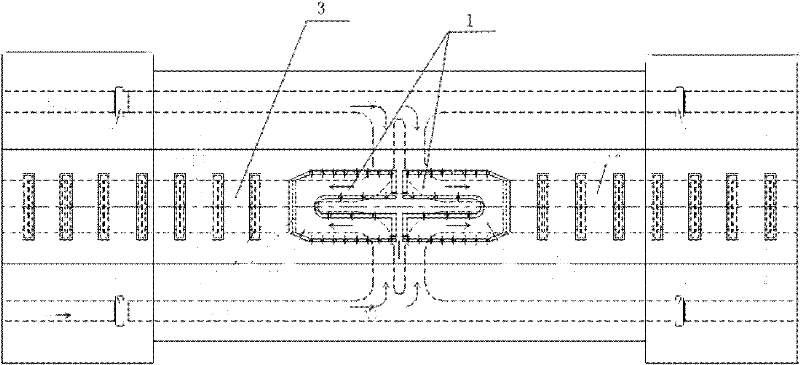

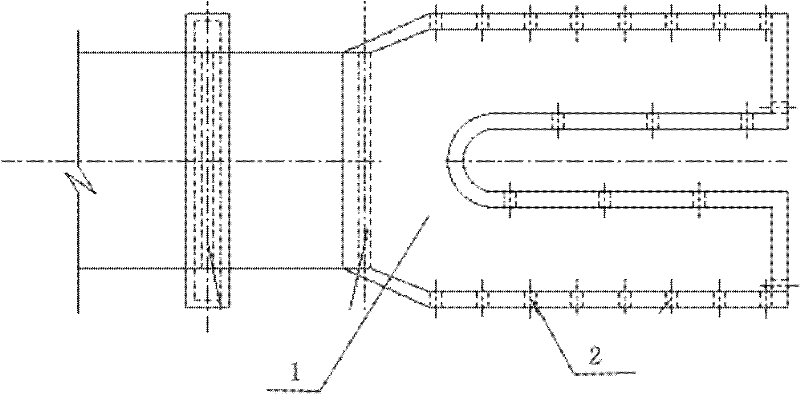

[0019] This embodiment is an engineering structure for improving the water and sand conditions in the lock chamber of the multi-section dispersed water delivery system of the ship lock, such as figure 1 As shown, that is, an auxiliary water outlet corridor 1 is added on the side of the non-water outlet area near the first and last two water outlet branch holes of each branch corridor 3 in each water outlet section. In this embodiment, the ship lock adopts a water conveyance system type with a long corridor on the lock wall, a horizontal diversion in the center of the lock chamber, and water outlets from two sections of the longitudinal long corridor at the bottom of the lock chamber. A U-shaped auxiliary water outlet corridor 1 is respectively set above the water outlet holes on the top. The minimum submerged water depth at the top of the auxiliary water outlet corridor is not less than the threshold water depth of the ship lock; there are several water outlet square holes 2 on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com