Prestressed steel cylinder concrete push pipe

A technology of prestressed steel and reinforced concrete, applied in the direction of pipes, rigid pipes, pipes/pipe joints/fittings, etc., can solve the problems of high cost, high amount of reinforcement, long construction period, etc., and achieve long service life and project cost. The effect of low and fast construction speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

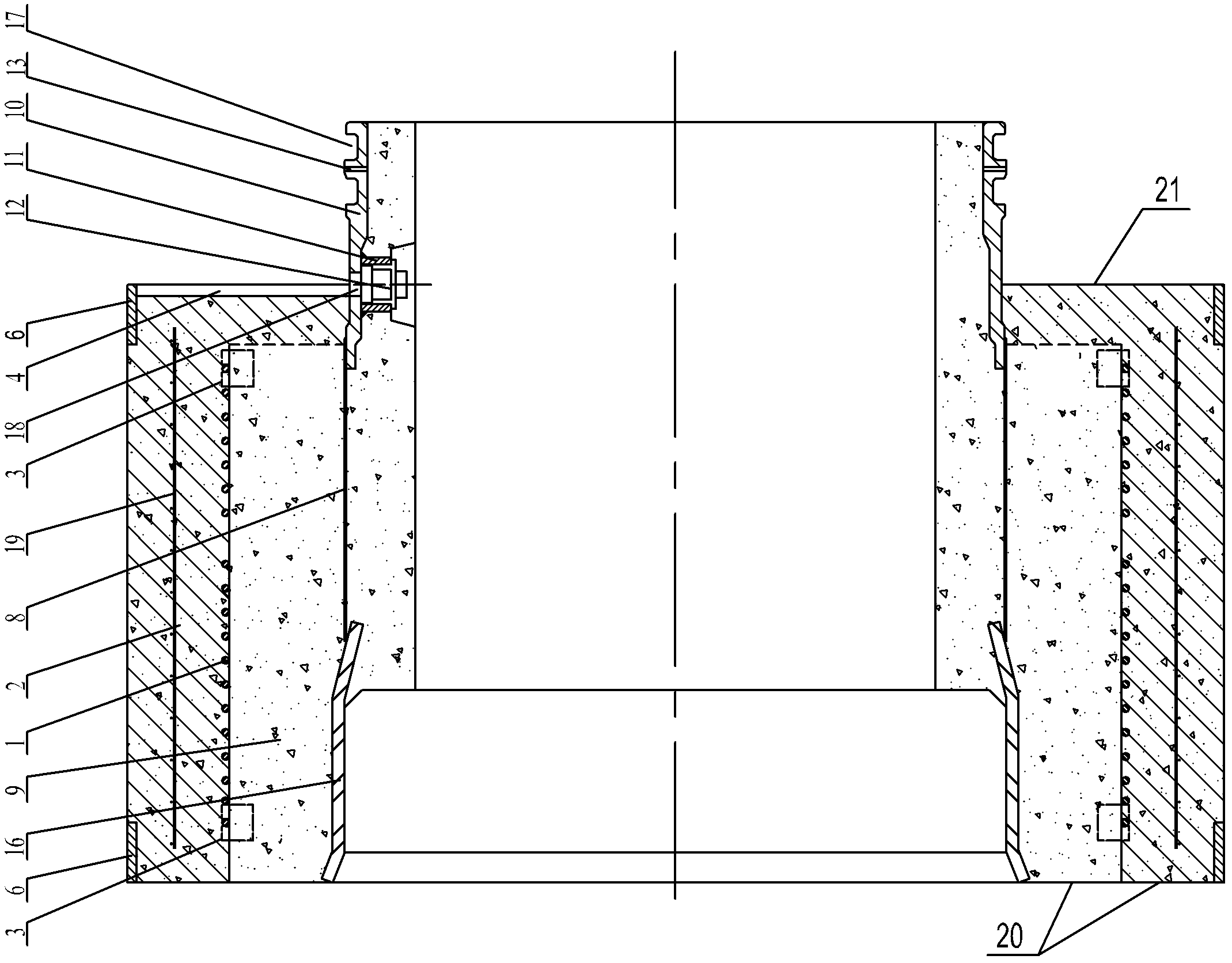

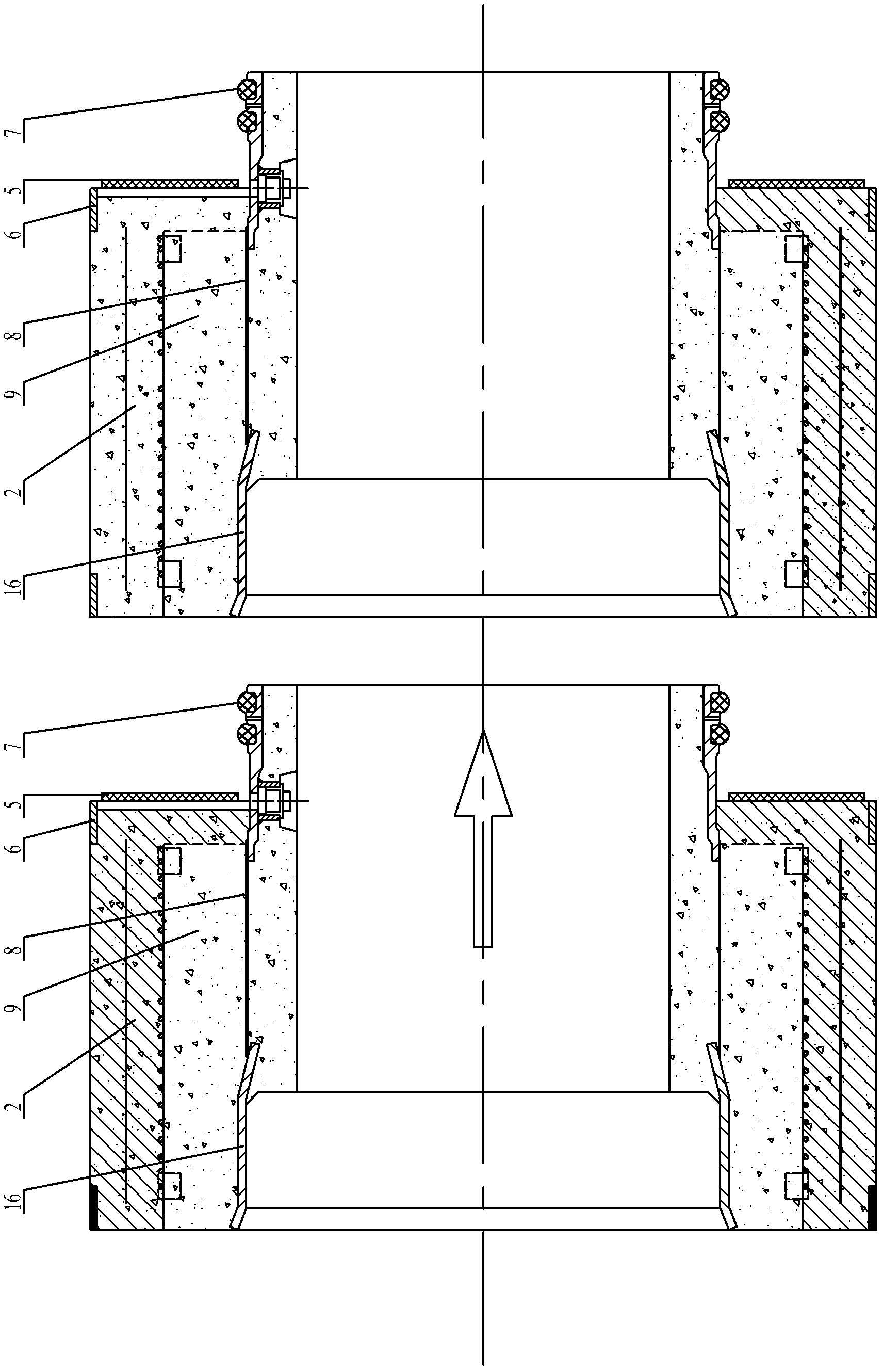

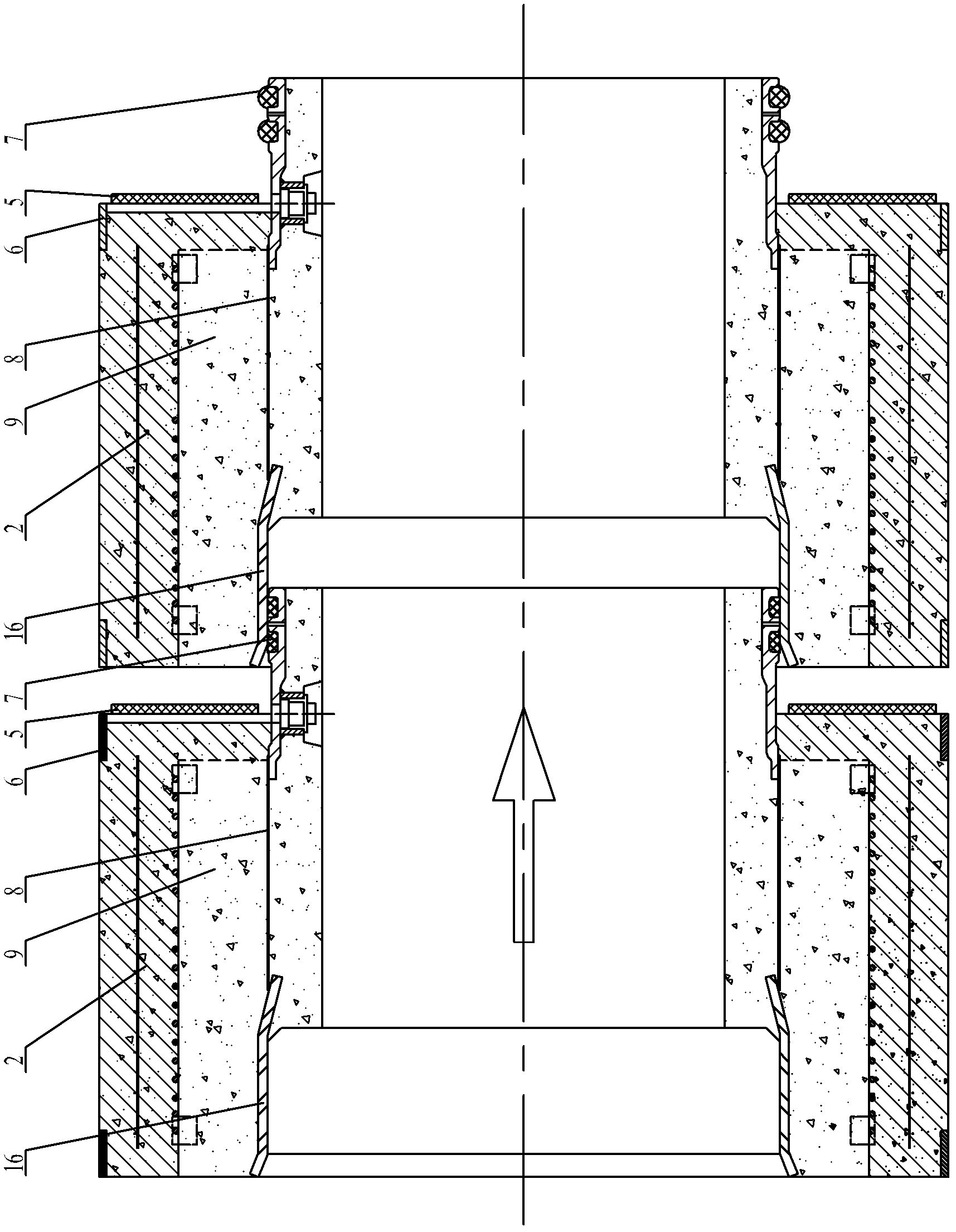

[0016] The present invention will be further described below in conjunction with specific drawings and embodiments.

[0017] As shown in the figure, the prestressed steel cylinder concrete pipe jacking includes the outer ring reinforced concrete 2 cast outside the concrete tube core 9, and the socket end face of the concrete tube core 9 is flush with the bottom end face of the outer ring reinforced concrete 2 , when the upper end of the outer ring reinforced concrete 2 is poured, it exceeds the concrete top surface of the outer part of the steel cylinder at the socket end of the concrete pipe core 9 by a certain height and covers it to form a complete plane. When the pipe is jacked, the jacking force can be evenly distributed to Outer ring reinforced concrete 2 and the outer part of the steel cylinder of the concrete pipe core 9, the two ends of the concrete pipe core 9 have embedded steel wire anchors 3, which are used to fix the prestressed steel wire 1, and are fixed on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com