Coated solid dosage form

A solid preparation and coating technology, applied in the direction of anhydride/acid/halide active ingredients, etc., can solve the problems of non-existence and deliquescence, and achieve the effects of preventing deliquescence, improving stability, and excellent stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

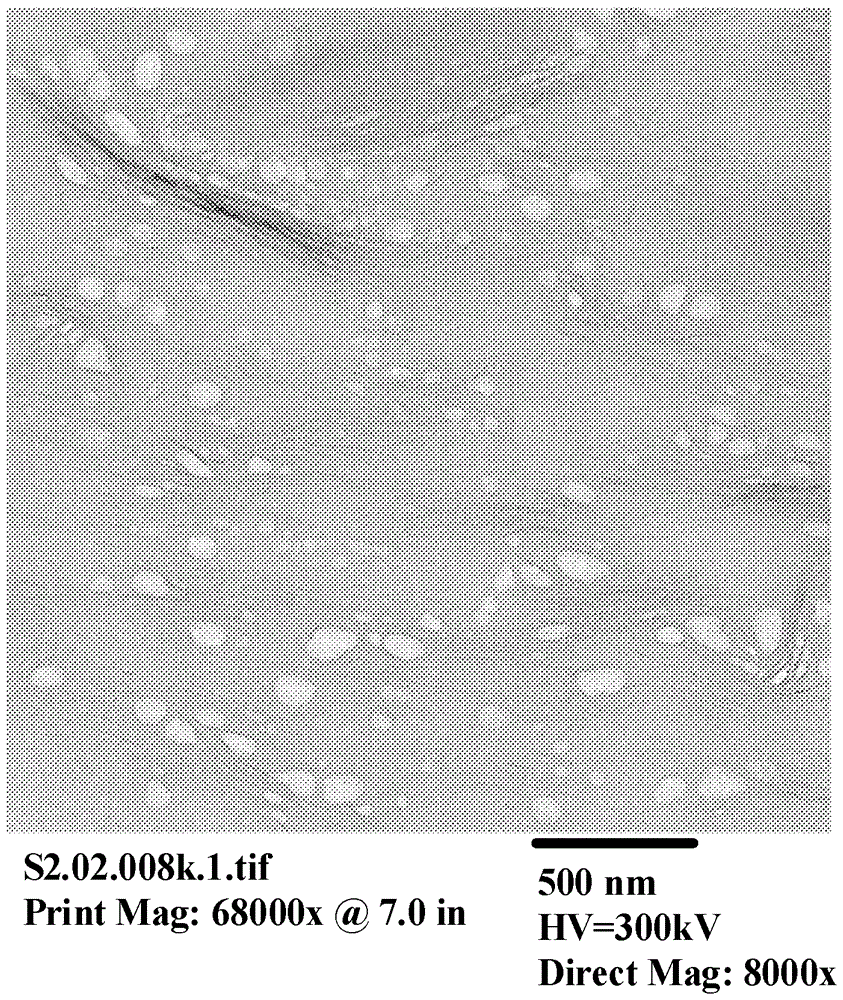

[0062] 10.0 parts by mass of polyvinyl alcohol (EG-05; Nippon Gosei Kagaku) and 312.5 parts by mass of bentonite solution were added to 177.5 parts by mass of water, and stirred with a homogenizer (Polytron Model KR) to obtain a coating material. 3.2% bentonite solution The following solution was used: Add 32 parts by mass of bentonite (Kunipia-F; Kunimine Industries Co. Ltd., cation exchange capacity: 115meq / 100g) to 968 parts by mass of stirred water, and make it Uniformly disperse the solution after suction filtration with filter paper. Hereinafter, polyvinyl alcohol is abbreviated as PVA, and bentonite is abbreviated as BT, respectively.

[0063] The sodium valproate sustained-release tablet (Selenica R200mg; Xinghe Co., Ltd.) of 200g is put into a coating pan (DRC-200; Powrex company), and the coating material prepared in Example 1 is coated on the tablet to make it The thickness reaches 20 μm. The obtained coated solid preparation was observed for changes in the exte...

Embodiment 6

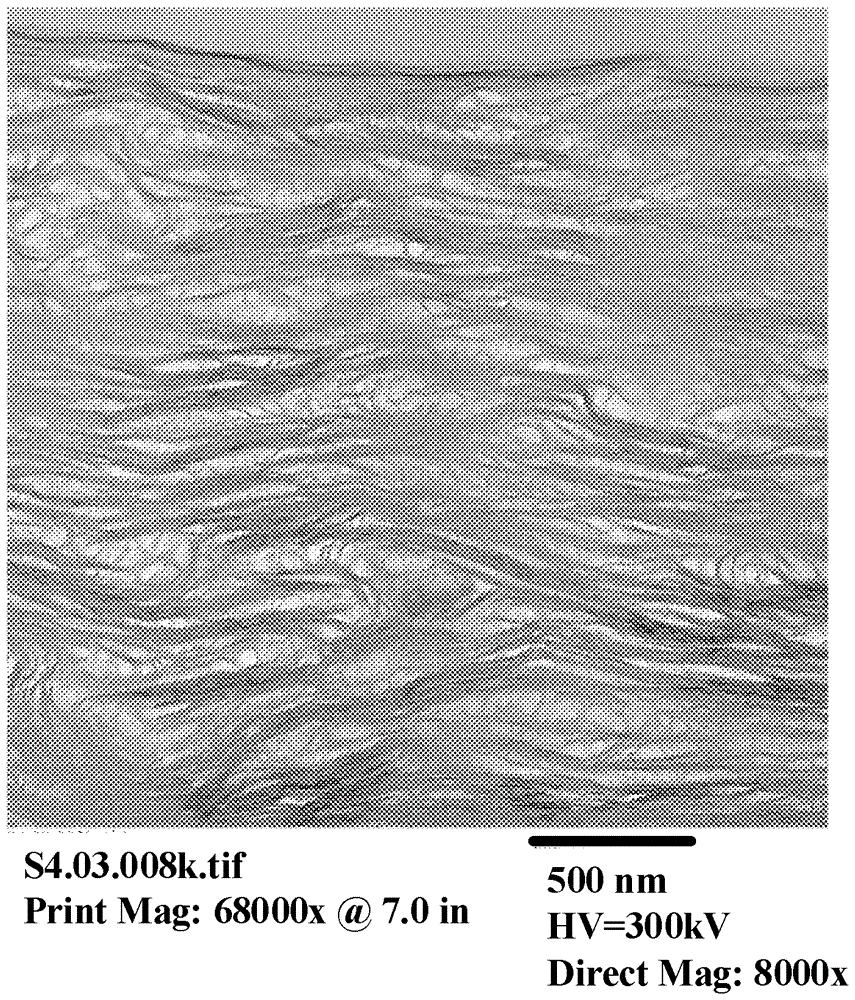

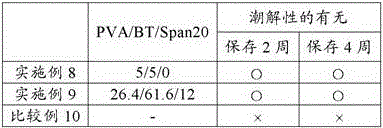

[0076] (Example 6) To 17.32 parts by mass of water and 390.0 parts by mass of ethanol, add 5.28 parts by mass of PVA, 385.0 parts by mass of BT solution, and 2.4 parts by mass of sorbitan monolaurate, and stir with a homogenizer , to obtain the coating material. The film was obtained by the method of Example 1, and the water vapor permeability was measured. Hereinafter, sorbitan monolaurate may be abbreviated as Span20.

Embodiment 7

[0085] (Example 7) A dissolution test was performed on the coated tablet obtained in Example 6 and the tablet obtained by leaving the present tablet under the conditions of 25° C. and 60% RH. In the dissolution test, according to the second method of the dissolution test method of the fifteenth revision of the Japanese Pharmacopoeia, the tablet was put into 900 mL of distilled water, and the dissolution rate of the drug was quantified by HPLC at 8 hours, 11 hours, and 20 hours after the start of dissolution.

[0086] (HPLC conditions)

[0087] Mobile phase: 50mM sodium dihydrogen phosphate / acetonitrile=5 / 5(v / v)

[0088] Column: Devolosil ODS-5 (4.6×150mm)

[0089] Detection wavelength: 210nm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com