Fiber reinforced thermoplastic composite material direct online pultrusion moulding device

A composite material and pultrusion technology, which is applied in the field of composite pultrusion, can solve problems such as wear and product performance degradation, and achieve the effects of reducing production input costs, excellent performance, and flexible settings.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

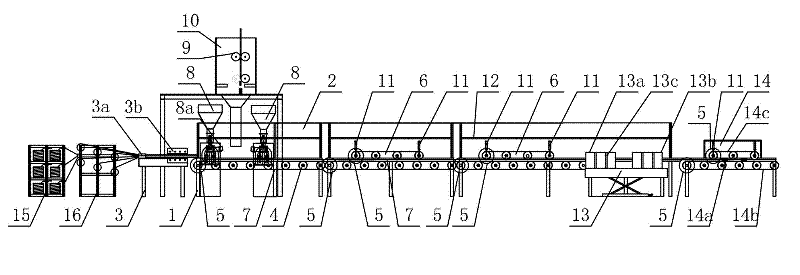

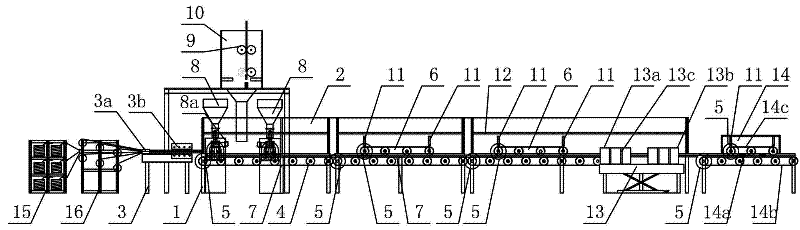

[0014] As shown in the figure: the composite material pultrusion molding machine is equipped with a yarn feeding mechanism (15), a felt feeding mechanism (16), a fiber weaving platform (3), a constant temperature stainless steel belt composite mechanism, Mold table (13), traction mechanism (14) and cutting mechanism. The yarn feeding mechanism (15) and the felt feeding mechanism (16) are located at the head of the whole set, and the yarn feeding mechanism (15) and the felt feeding mechanism (16) are respectively equipped with a The tight state is sent to the following tension yarn release and tension felt release structure. The tension yarn release and tension felt release structure is composed of the prestressed damping shaft mechanism arranged vertically on the yarn supply mechanism (15) and the felt supply yarn passing mechanism (16). It is composed of a wheel shaft that is configured one-to-one with the prestressed damping shaft mechanism.

[0015] The front end of the fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com