Double-lip oil seal device capable of regulating pressure automatically

A technology of automatic pressure regulation and lip oil, applied in the direction of engine seals, engine components, mechanical equipment, etc., can solve problems such as unstable internal pressure, reduce maintenance costs, improve service life, and facilitate disassembly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

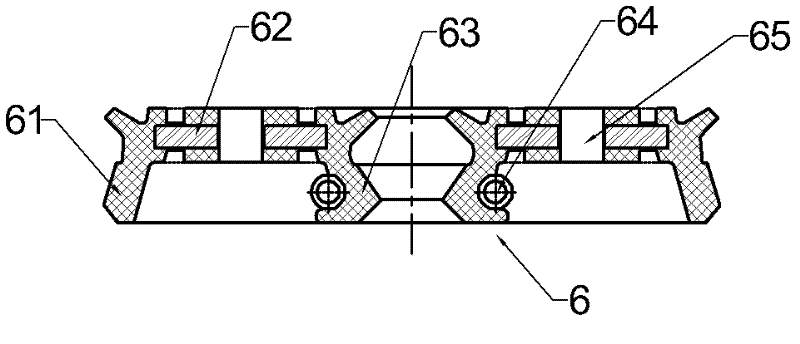

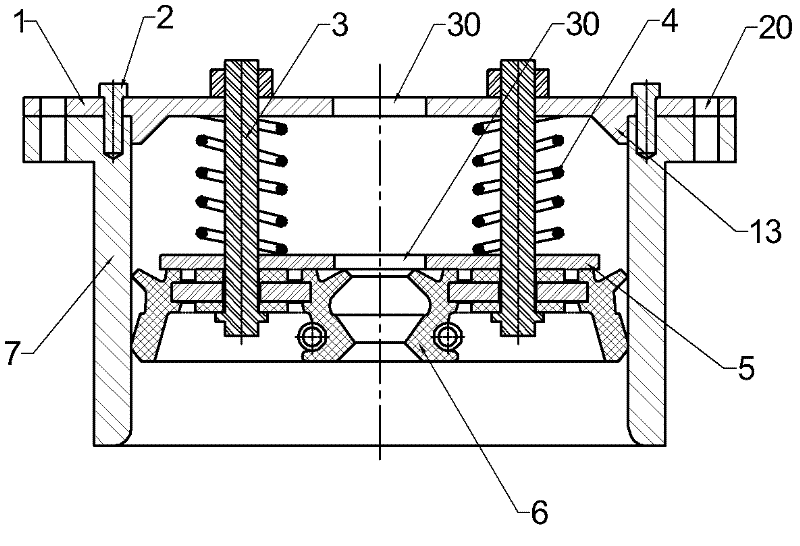

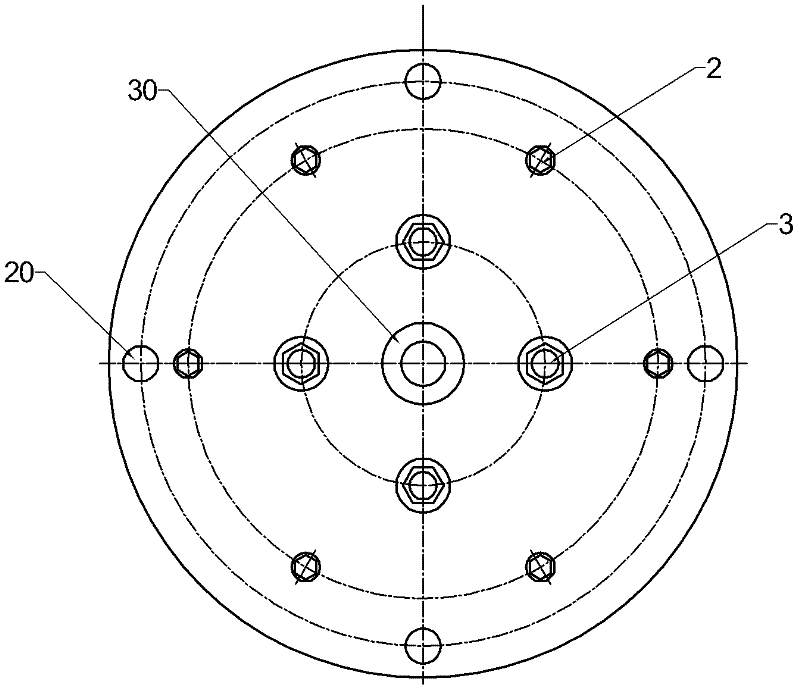

[0013] Referring to the accompanying drawings, an automatic pressure-regulating double-lip oil seal device includes a double-lip oil seal 6, a guide cylinder 7, a circular backing plate 5, a buffer spring 4, a guide screw 3 and a dome cover 1. The outer surface of the double-lip oil seal 6 The lip 61 and the inner wall of the guide cylinder 7 are slidably and airtightly bonded, the inner lip 63 of the double-lip oil seal 6 is slidably and airtightly bonded to the system working shaft 10, and the circular backing plate 5 is placed on the double-lip oil seal 6, on the round backing plate 5 there is a threaded hole that matches the guide screw 3, on the dome cover 1 there is a through hole that matches the guide screw 3, on the double-lip oil seal 6 there is a screw hole that matches the guide screw 3 The matched through hole 65, the through hole 65 on the double-lip oil seal 6 vertically passes through the metal skeleton 62 between the outer lip 61 and the inner lip 63 of the dou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com