Triple-extrusion optical fiber composite overhead insulating cable

An overhead insulated cable and optical fiber composite technology, which is applied in the direction of power cables with shielding layers/conductive layers, power cables, cables, etc., can solve the problem that optical fibers need to go through secondary wiring when laying alone, so as to save polyethylene materials and reduce The effect of small thickness and easy laying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

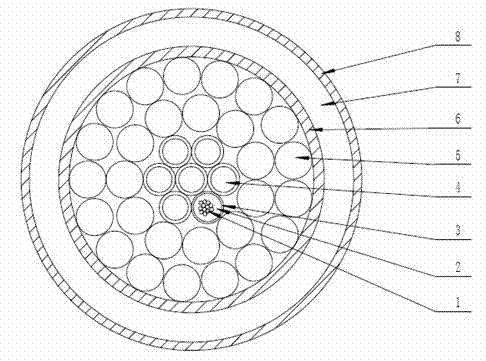

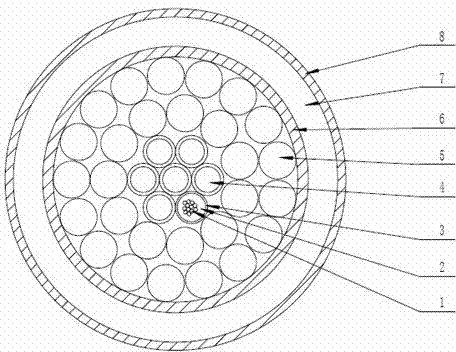

[0013] Such as figure 1 As shown, the center of the present invention is provided with a stainless steel tube 3, a plurality of optical fibers 1 are placed in the stainless steel tube 3, and filled with optical fiber ointment 2 to form an optical unit, and the optical unit is twisted with several aluminum-clad steel wires or galvanized steel wires 4 to form a guide In the inner layer, hard aluminum wires 5 are twisted outside the inner layer of the conductor to form a conductor, and a conductor shielding layer 6, a main insulating layer of cross-linked polyethylene 7, and an outer insulating layer 8 of weather-resistant cross-linked polyethylene are arranged in sequence outside the conductor. The conductor shielding layer 6, the main insulating layer of cross-linked polyethylene 7, and the outer insulating layer 8 of weather-resistant cross-linked polyethylene are formed by three-layer co-extrusion.

[0014] In the present invention, the insulating layer is changed from a trad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com