Measuring device for electrically measuring a flat measurement structure that can be contacted on one side

A measurement device and electrical measurement technology, applied in the field of measurement structure, can solve the problems of distortion of measurement results, time-consuming, loading of electromagnetic radiation, etc., and achieve the effect of accelerating the speed of connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

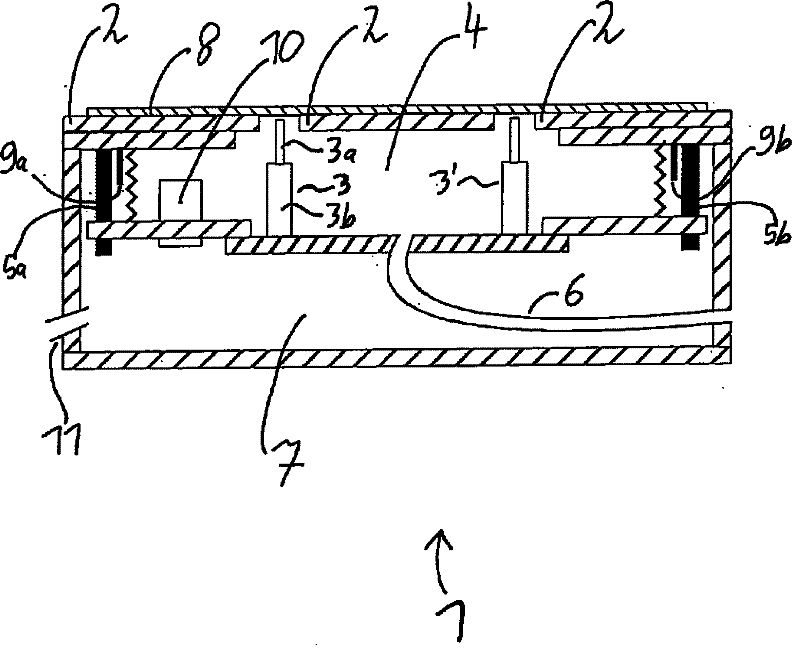

[0065] figure 1 A cross-sectional view of an embodiment of the measuring device 1 according to the invention is shown, which runs perpendicular to the support element 2. The supporting element 2 is formed in one piece and has two notches, figure 1 The cross-sectional view shown in extends through the gap.

[0066] The measuring device has multiple switch-on units 3, figure 1 The cross-sectional view shown shows two of them (3, 3'). The connection unit 3 is designed as a spring contact pin with a pin 3a, figure 1 The pin in the cylinder is supported in the cylindrical housing 3b so as to move upward and downward. The pin 3a is loaded by the spring, so that the pin moves upward in the unloaded state.

[0067] The switch-on unit 3 is provided on the bottom element of the first vacuum chamber 4. The vacuum chamber passes upwards through the support element 2 and downwards is defined by the bottom element. The vacuum chamber is sealed on the side by bellows elements. In addition, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com