Concentrated orange juice and manufacturing method thereof

A technology for concentrating orange juice and a production method, which is applied in the field of fruit juice beverages, can solve the problems of high production cost, easy color change, and pulp sinking, etc., and achieves the effects of reducing production cost, difficult color, and fresh and sweet taste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

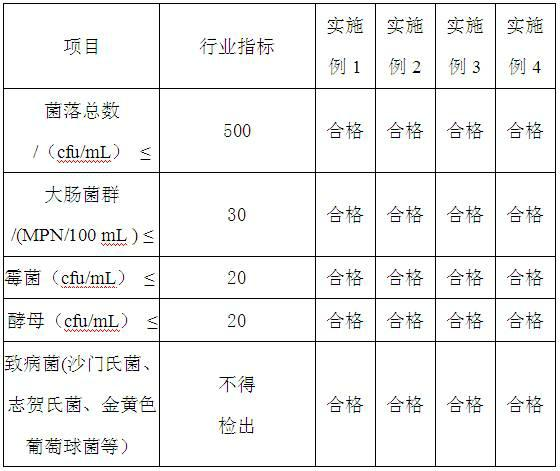

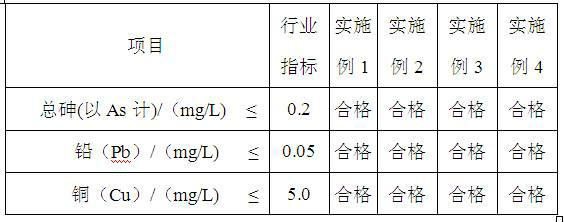

Examples

Embodiment 1

[0063] A concentrated orange juice comprising the following raw materials in parts by weight: 35 parts of orange juice pulp, 20 parts of sugar, 2 parts of citric acid, 0.39975 parts of malic acid, 4 parts of modified starch, 0.3 part of xanthan gum, 0.3 part of pectin, and 0.00025 parts of sodium sulfite parts, 38 parts of water.

[0064] A method for making concentrated orange juice, comprising the following steps: a. Raw material preparation: weighing the raw materials according to the above weight parts; b. Homogenizing: mixing (xanthan gum+pectin): water at a ratio of 1:20 to Colloidal mixture, use a colloid mill to grind and homogenize the colloidal mixture; c. Boil water: put the raw sugar, remaining water and the colloidal mixture processed in step b into a container, heat the water to 80°C, and heat it while heating Stirring; d. Gelatinization: Heat the water in step c to 95°C, put the modified starch into the container, and stir for 8 minutes; e. Blending: Add orange ...

Embodiment 2

[0067] A concentrated orange juice comprising the following raw materials in parts by weight: 38 parts of orange juice pulp, 25 parts of sugar, 1 part of citric acid, 0.5 part of malic acid, 4 parts of modified starch, 0.1 part of xanthan gum, 0.2 part of pectin, 0.00025 parts of sodium sulfite, 45 parts of water.

[0068]A method for making concentrated orange juice, comprising the following steps: a. Raw material preparation: weighing the raw materials according to the above weight parts; b. Homogenizing: mixing (xanthan gum + pectin): water at a ratio of 1:15 to Colloidal mixture, use a colloid mill to grind and homogenize the colloidal mixture; c. Boil water: put the raw sugar, remaining water and the colloidal mixture processed in step b into a container, heat the water to 85°C, and heat it while heating Stirring; d. Gelatinization: Heat the water in step c to 95°C, put the modified starch into the container, and stir for 5 minutes; e. Blending: Add orange juice pulp, cit...

Embodiment 3

[0071] A concentrated orange juice comprising the following raw materials in parts by weight: 42 parts of orange juice pulp, 18 parts of sugar, 3 parts of citric acid, 0.1 part of malic acid, 3 parts of modified starch, 0.2 part of xanthan gum, 0.1 part of pectin, and 0.0001 part of sodium sulfite parts, 35 parts of water.

[0072] A method for making concentrated orange juice, comprising the following steps: a. Raw material preparation: weighing the raw materials according to the above weight parts; b. Homogenizing: mixing (xanthan gum + pectin): water at a ratio of 1:10 to Colloidal mixture, use a colloid mill to grind and homogenize the colloidal mixture; c. Boil water: put the raw sugar, remaining water and the colloidal mixture processed in step b into a container, heat the water to 88°C, and heat it while heating Stirring; d. Gelatinization: Heat the water in step c to 95°C, put the modified starch into the container, and stir for 6 minutes; e. Blending: Add orange juice...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com