Upper oscillating arm assembly of automobile double-wishbone suspension

A double-wishbone and assembly technology, which is applied in the direction of suspension, vehicle parts, cantilever installed on the pivot, etc., can solve the problem of difficult control of welding assembly deformation, heavy non-suspension quality of suspension, and upper swing arm assembly Heavy weight and other issues, to achieve the effect of reducing non-suspended mass, simplifying processing procedures and assembly processes, and reducing manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

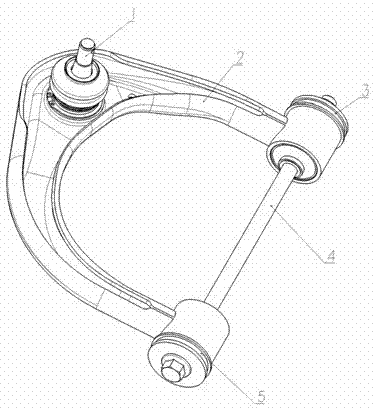

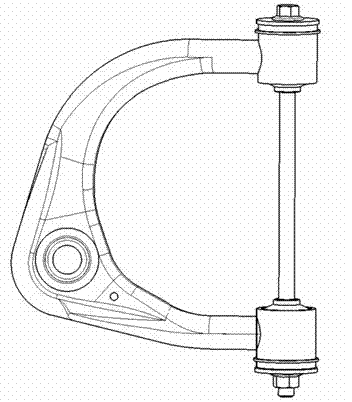

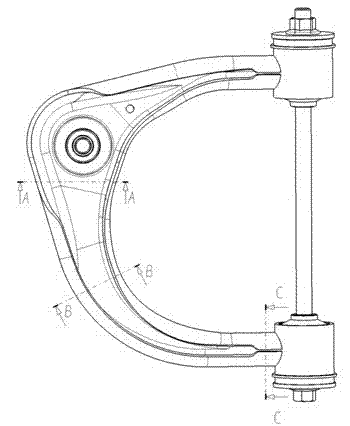

[0020] Such as Figure 1~5 As shown, the upper swing arm assembly of the automobile double-wishbone suspension in this embodiment includes the upper swing arm body 2 on which the ball stud assembly 1 is installed, and the two free ends of the upper swing arm body 2 are respectively pressed in an interference manner. Front bush 5, rear bush 3 are housed, and utilize a long bolt 4 to connect, and front bush 5, rear bush 3 are coaxial.

[0021] Such as Figure 1-8 As shown, the upper swing arm body 2 is stamped and formed by a single-layer steel plate. The cross section of the upper swing arm body 2 is in the shape of a groove with the opening downward, and the opening of the groove is from the ball stud assembly 1 to the free ends of both ends. gradually decreases. Wherein, the cross-sectional shape of the upper swing arm body 2 at the ball stud assembly 1 is groove-shaped, and one side of the bottom of the groove has an additional groove 6, which can further strengthen the be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com