High efficiency halogen-free flame retardant polypropylene composite material and its preparation method

A technology of flame-retardant polypropylene and composite materials, which is applied in the field of flame-retardant polypropylene materials, can solve the problems of low flame-retardant efficiency and high water solubility, and achieve the effects of high flame-retardant efficiency, low smoke density, and small smoke emission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

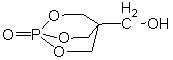

Embodiment 1

[0027] Accurately weigh 0.67kg of ammonium polyphosphate (APP), 0.33kg of pentaerythritol phosphate (PEPA), 0.015kg of antioxidant, and 0.005kg of zinc stearate, and pre-mix them in a high-speed dispersant for 5 minutes to obtain a halogen-free flame retardant compound; then add 3.98 kg of polypropylene pellets into the above-mentioned high-speed disperser, stir for 8 minutes, and then put the above-mentioned mixture into a twin-screw extruder for extrusion, cooling, and granulation to obtain halogen-free resistors. Combustible polypropylene composite. Wherein, the temperature of each zone of the twin-screw extruder is 150-200°C. The oxygen index of the polypropylene composite material is 27.0%, and the UL-94 test reaches the V-0 level. In this embodiment, the antioxidant is 1010 or 168, and one or more mixtures of stearic acid, calcium stearate, and polypropylene wax can also be used instead of zinc stearate. Ammonium polyphosphate (APP) is high degree of polymerization cry...

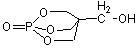

Embodiment 2

[0032] Accurately weigh 0.67kg of ammonium polyphosphate (APP), 0.33kg of pentaerythritol phosphate (PEPA), 0.015kg of antioxidant, 0.005kg of calcium stearate, and 0.10kg of manganese dioxide, and pre-mix them in a high-speed dispersant for 10 minutes to obtain Halogen-free flame retardant compound; then add 3.88 kg of polypropylene pellets into the above-mentioned high-speed disperser, and stir for 10 minutes; then put the above-mentioned mixture into a twin-screw extruder for extrusion, cooling, and granulation, that is Halogen-free flame-retardant polypropylene composites are available. Wherein, the temperature of each zone of the twin-screw extruder is set at 150-200°C. The oxygen index of the polypropylene composite material is 31.0%, and the UL-94 test reaches the V-0 level. In this embodiment, one or more mixtures of zinc oxide and nano silicon dioxide can also be used instead of manganese dioxide, the antioxidant is 1010 or 168, and stearic acid, zinc stearate, polyp...

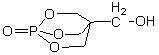

Embodiment 3

[0038]Accurately weigh 0.67kg of ammonium polyphosphate (APP), 0.33kg of pentaerythritol phosphate (PEPA), 0.015kg of antioxidant, 0.005kg of stearic acid, and 0.05kg of zinc oxide, and pre-mix them in a high-speed dispersant for 20 minutes to obtain Halogen flame retardant; then 3.93kg of polypropylene pellets are added to the above-mentioned high-speed disperser, and stirred for 20 minutes; then the above-mentioned mixture is put into a twin-screw extruder for extrusion, cooling, and granulation to obtain Halogen-free flame retardant polypropylene compound. Wherein, the temperature of each zone of the twin-screw extruder is set at 150-200°C. The oxygen index of the polypropylene composite material is 29.0%, and the UL-94 test reaches the V-0 level. In this embodiment, one or more mixtures of manganese dioxide and nano silicon dioxide can also be used instead of zinc oxide, the antioxidant is 1010 or 168, calcium stearate, zinc stearate, polypropylene wax can also be used O...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com