Hairpiece

A wig and hair technology, applied in the field of wigs, can solve the problems of difficulty in producing a sense of volume, limited hairstyle, poor three-dimensional sense, etc., and achieves the effects of easy combing and other operations, improved clustering, and improved volume.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0130] Embodiments of the present invention will be described in more detail below by describing examples.

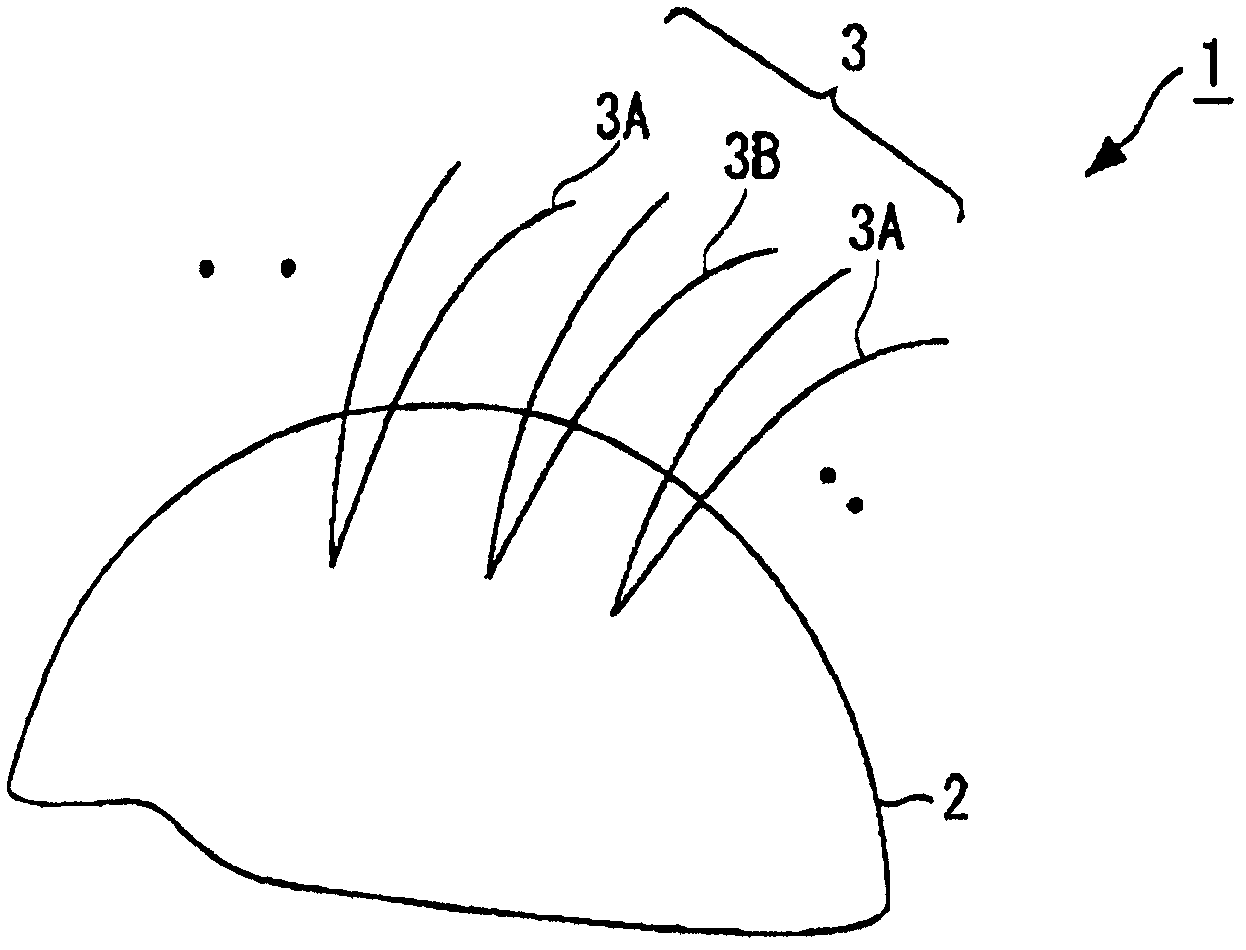

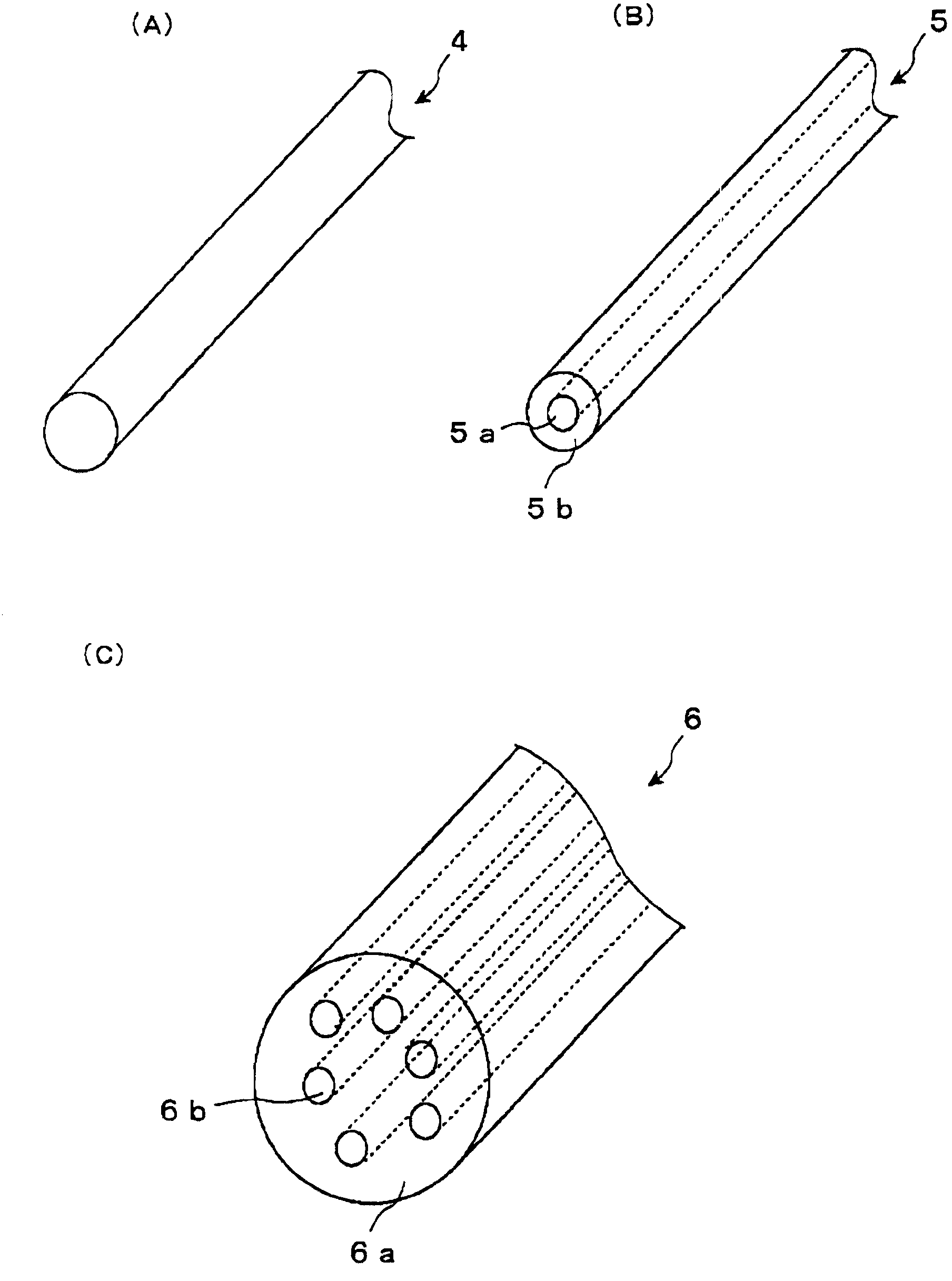

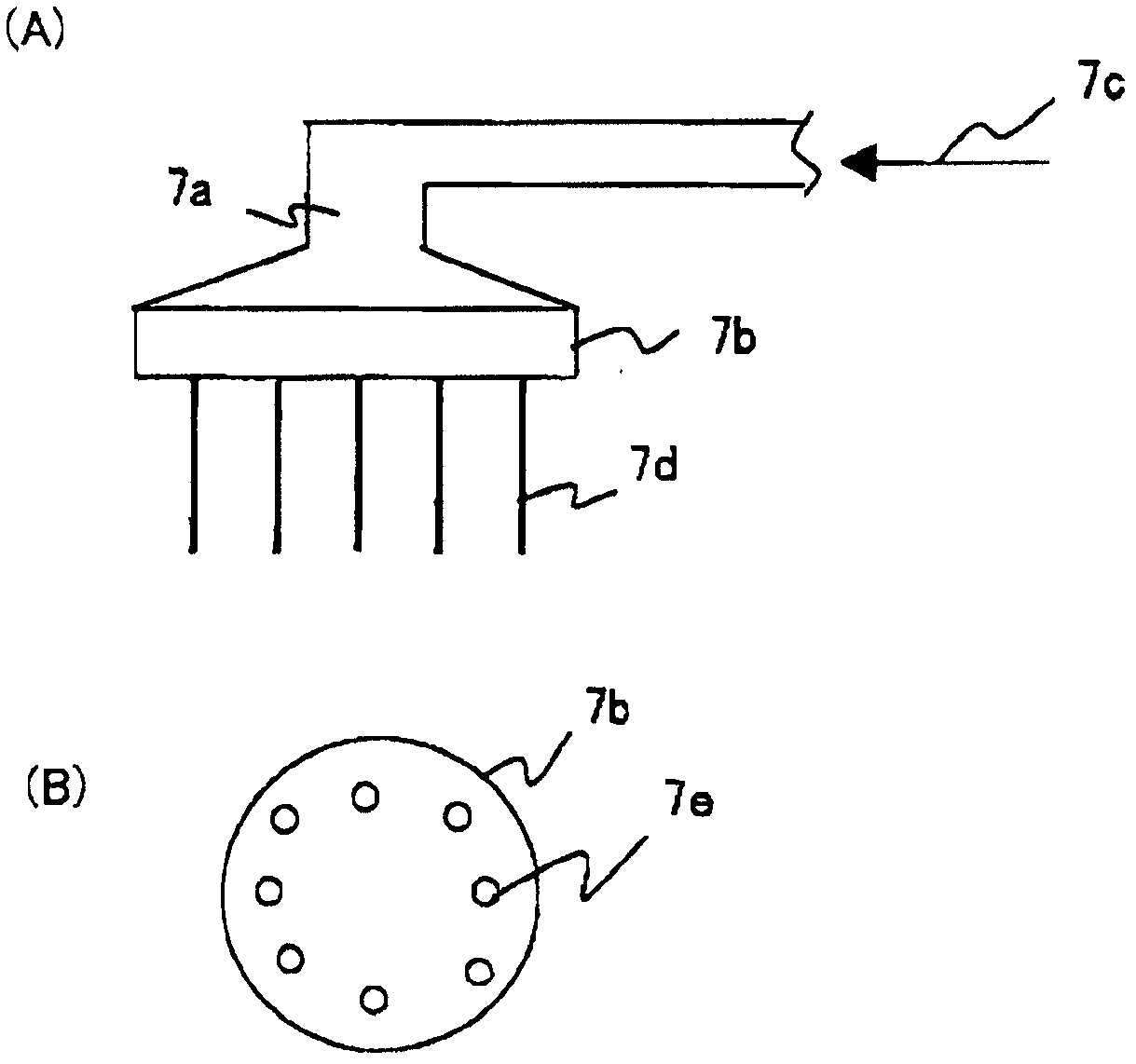

[0131] In any of the examples and comparative examples, the preparation conditions are set so that the diameter reaches approximately 80 μm, the first artificial hair 3A and the second artificial hair 3B are prepared, and the respective bending rigidity values of the first and second artificial hair 3A and 3B are measured. . In each embodiment and comparative example, the first artificial hair 3A and the second artificial hair are mixed in different proportions to prepare artificial hair bundles, and a 20cm-long hair bundle is pre-wrapped on an aluminum tube with a diameter of 25mm, and heat-treated Curl was imparted, the hair bundle was folded in half so that it had a length of 10 cm, and each hair was bonded to a net base of 5 cm×5 cm to prepare a sample. The sample was used for property evaluation as hair.

[0132] In Example 1, as the first artificial hair 3A, f...

Embodiment 2

[0136] In Example 2, the nylon 6 (PA6) fiber prepared in Example 1 was used for the first artificial hair 3A.

[0137] As the second artificial hair, fibers having a perfect circular cross-sectional shape and a sheath-core structure were prepared. Specifically, as the raw material chip of the part constituting the core, MX nylon grade nylon MXD6 (PAMXD6) chip manufactured by Mitsubishi Gas Chemical Company, Inc. was used, and as the raw material chip of the part constituting the sheath, NOVAMID 1020 manufactured by Mitsubishi Engineering-Plastics Corporation was used. Grade nylon 6 (PA6) slices, the weight ratio of nylon MXD6 slices and nylon 6 slices is set to 72:25. use Figure 4 In the production system of (B), the roll speeds of the first stretching roll to the fourth stretching rolls 15, 17, 19, and 22 were adjusted, and as a result, the cross-sectional diameter of the fiber was 81.6 μm. Here, since the diameter of the core is 72.9 μm, the cross-sectional dimension of t...

Embodiment 3

[0140] In Example 3, the nylon 6 (PA6) fiber prepared in Example 1 was used for the first artificial hair 3A.

[0141] As the second artificial hair, fibers having a perfect circular cross-sectional shape and a sea-island structure were prepared. Specifically, as the raw material slices of the part constituting the matrix (i.e., the sea portion), MX nylon grade nylon MXD6 (PAMXD6) slices manufactured by Mitsubishi Gas Chemical Company, Inc. were used, and as the raw material slices constituting the island portion, Mitsubishi Engineering-Plastics For nylon 6 (PA6) chips of NOVAMID 1020 grade manufactured by Corporation, the weight ratio of nylon MXD6 chips to nylon 6 chips was set to 65:35. The speed of each stretching roll was adjusted in the same manner as in Example 1 and Example 2, and as a result, the cross-sectional diameter of the fiber was 83.2 μm. Here, the cross-sectional structure in the axial direction of the second artificial hair is a structure in which there is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com