Full-cloth-width patient transferring bed surface and motion control structure thereof

A technology for picking up and delivering beds and patients, which is applied in the fields of hospital beds, medical science, and hospital equipment. It can solve the problems that the bed panel movement space is greatly affected, the effective working bed surface is small, and the driving structure is complicated, so as to increase the effective working area and move. Smooth, driving force delivery Direct and reliable results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

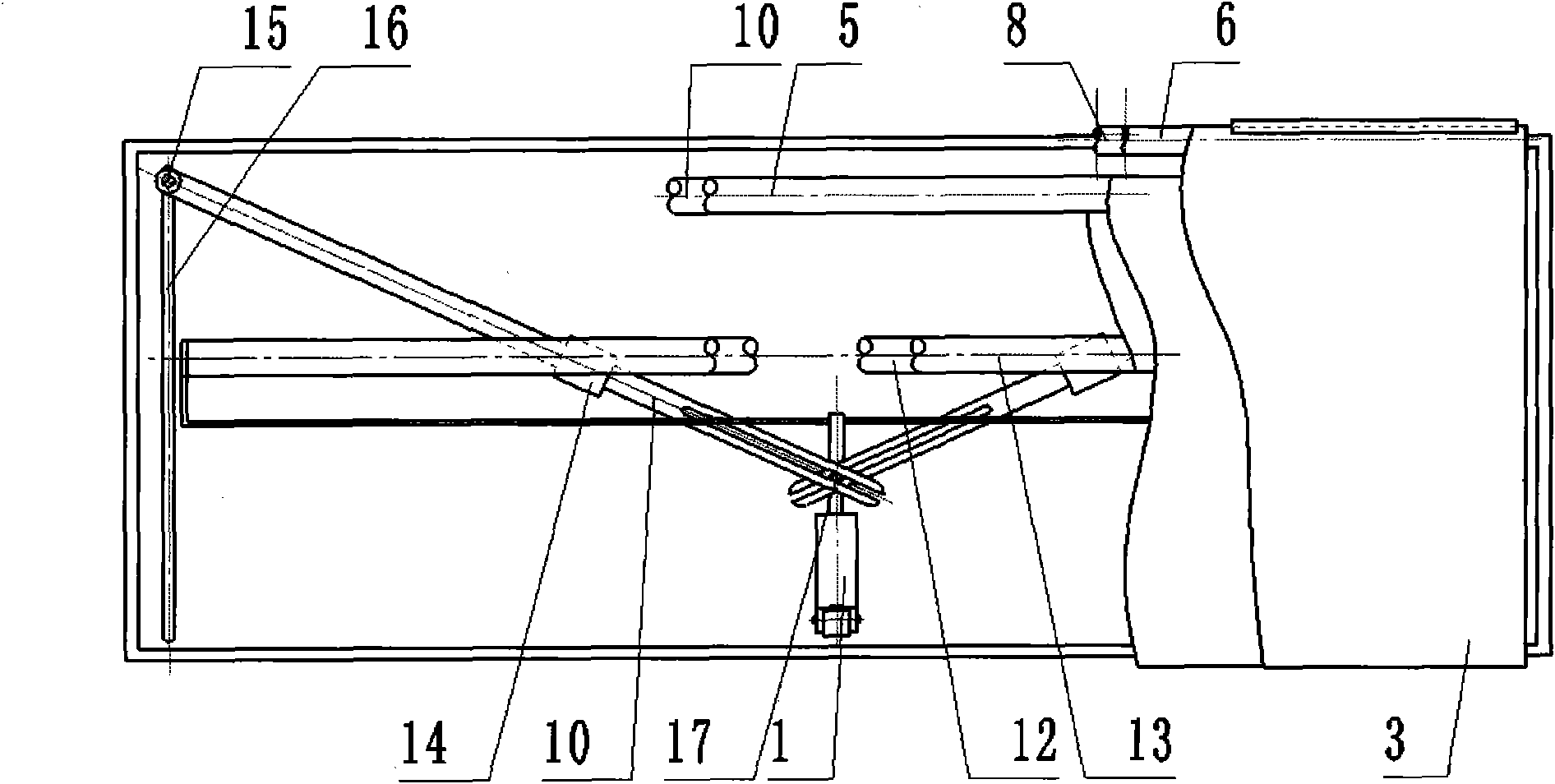

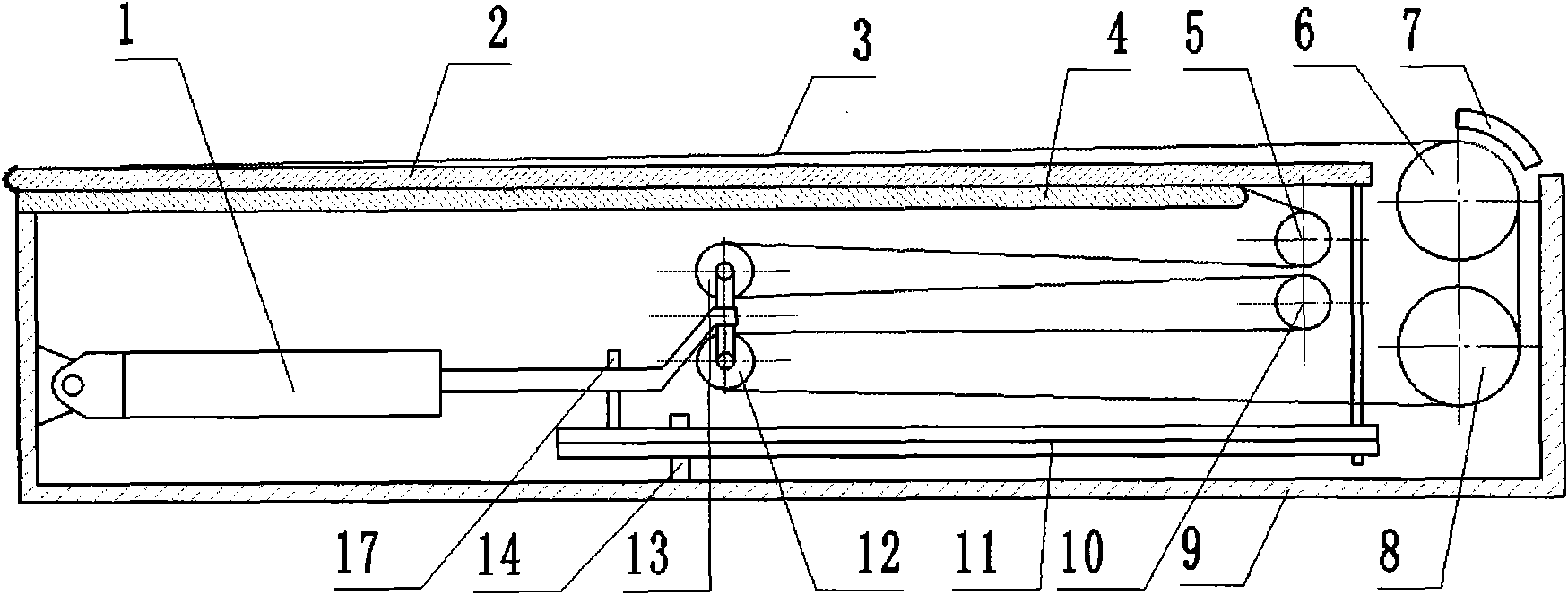

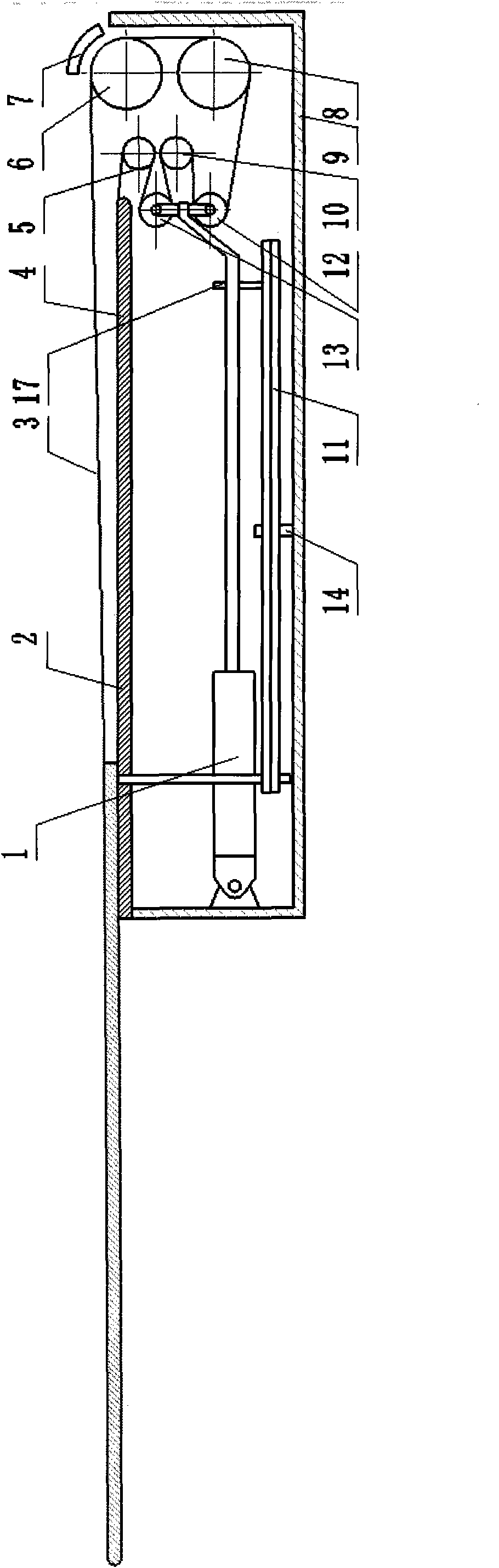

[0014] figure 1 Among them, the electric push rod or electro-hydraulic push rod (1) can do linear telescopic movement, and the sliding fulcrum (14) has a transfer pair with the bed frame (4), and a linear movement pair with the paddle bar (11). The paddle rod (11) is driven to rotate around the sliding fulcrum (14) by pushing the paddle pin (17), forming a lever structure. The two paddle rods arranged symmetrically have long slots at one end of the push rod push paddle pin (17), in which the push paddle pin (17) slides. The other end of the paddle bar (11) is fixedly connected to the bottom of the bed panel (2) through the rotating pair, thereby driving the bed panel (2) to expand and contract. Electric push rods or electro-hydraulic push rods (1) are connected together through rotating pairs at both ends of the moving rollers, thereby ensuring that the moving rollers move in the direction opposite to the direction in which the bed panel moves. The distance from the sliding ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com