Surfactant foam flushing technology for polychlorinated biphenyls (PCBs) polluted soil repair

A technology for polluted soil and foam, applied in the field of remediation, can solve the problem of ineffective removal of pollutants, gas or waste of foaming agent, etc., and achieve the effects of uniform size, low cost and improved sweep efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Embodiment 1 (conversion gas content):

[0028] Traditional foam flushing conditions: directly use nitrogen compressed bottle to supply gas, peristaltic pump to supply liquid, and inject the gas-liquid mixture into the polluted sand.

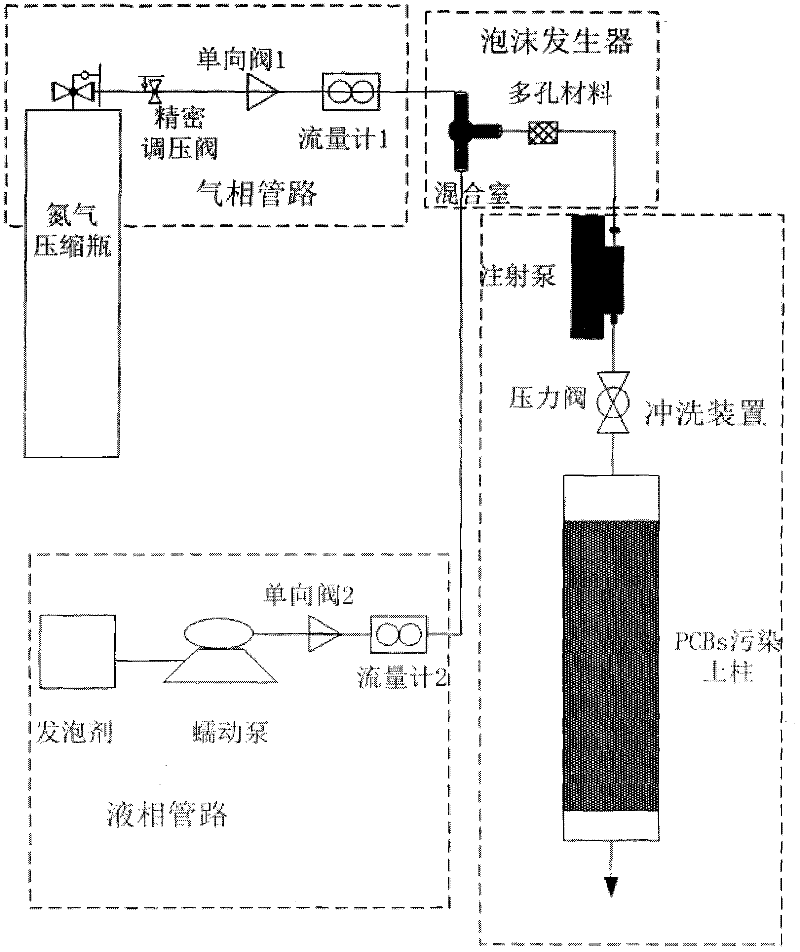

[0029] Flushing technology of the present invention, with reference to attached figure 1 , the foam is prepared by the device for preparing heterotopic foam, the device includes a nitrogen compression bottle, a pressure reducing valve, a precision pressure regulating valve, a one-way valve, a flow meter 1, a peristaltic pump, a flow meter 2, a gas-liquid mixing chamber, and a porous material (Consolidated sand core, average pore diameter 0.1mm). In the gas phase pipeline, a precision pressure regulating valve is installed after the pressure reducing valve, and then connected to the check valve 1 and the flow meter 1; in the liquid phase pipeline, the peristaltic pump is connected to the check valve 2 and the flow meter 2.

[0030] Use 7...

Embodiment 2

[0037] Embodiment 2 (conversion foam particle size)

[0038] Traditional foam flushing conditions: Directly use compressed air bottle to supply air, injection pump to supply liquid, and inject the air-liquid mixture into the polluted sand.

[0039] Flushing technology of the present invention, with reference to attached figure 1 , the foam is prepared by the device for preparing heterotopic foam, the device includes a nitrogen compression bottle, a pressure reducing valve, a precision pressure regulating valve, a one-way valve, a flow meter 1, a peristaltic pump, a flow meter 2, a gas-liquid mixing chamber, and a porous material (Metal aeration head, average aperture 0.1mm and 0.4mm). In the gas phase pipeline, a precision pressure regulating valve is installed after the pressure reducing valve, and then connected to the check valve 1 and the flow meter 1; in the liquid phase pipeline, the peristaltic pump is connected to the check valve 2 and the flow meter 2.

[0040] Use ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com