Oil displacement composition constructed by anionic amphiphilic polymer and its preparation method and application

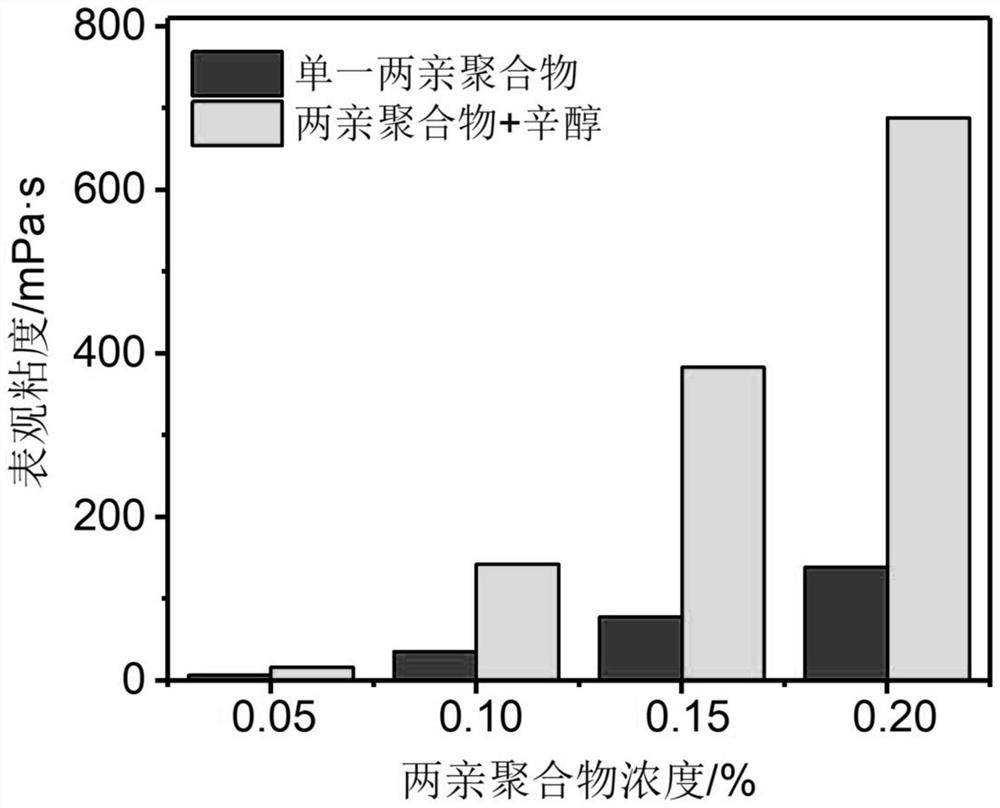

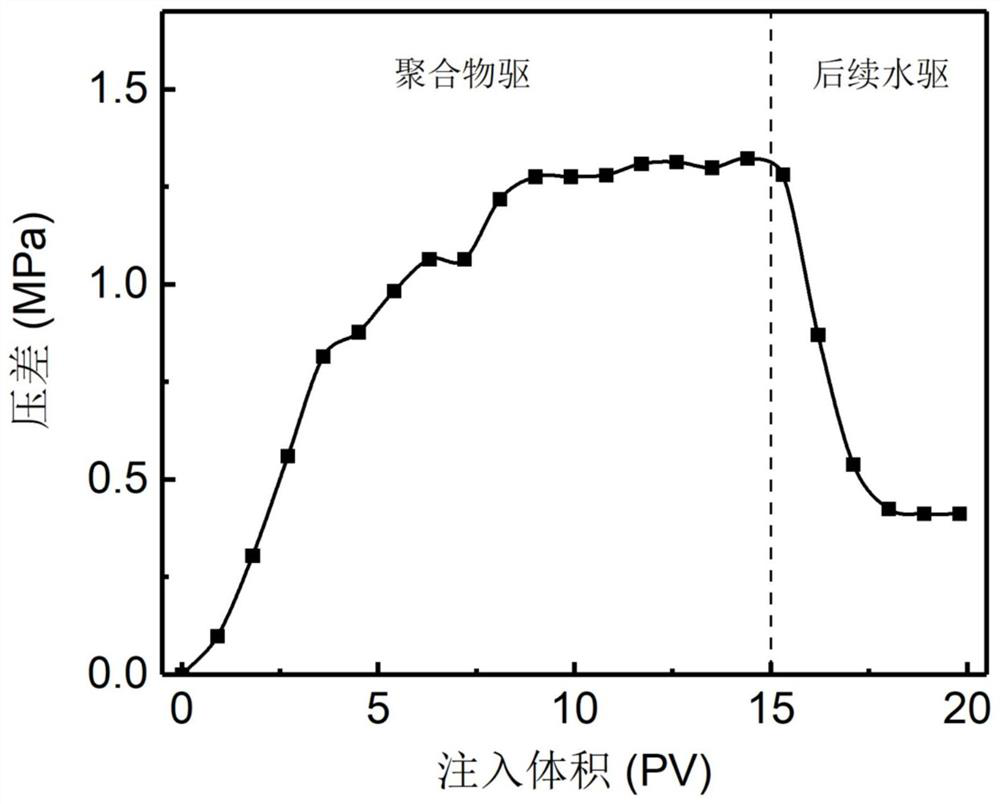

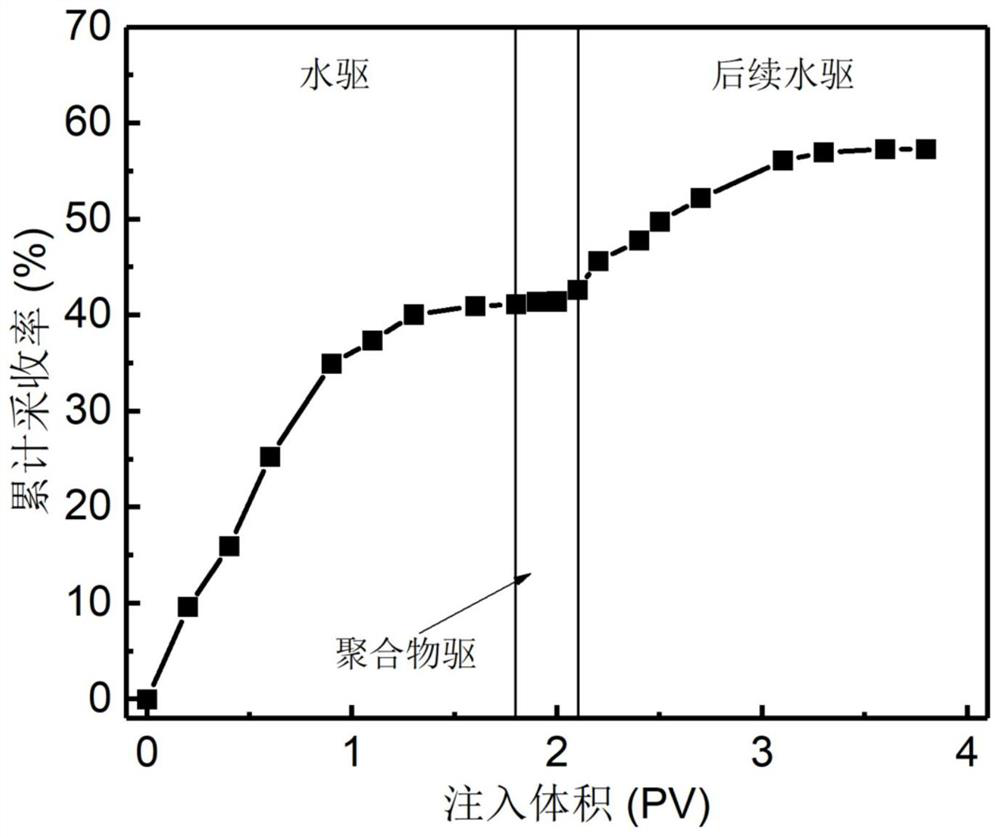

An amphiphilic polymer, anionic technology, applied in drilling compositions, chemical instruments and methods, etc., can solve problems such as economic effectiveness still needs to be improved, achieve excellent mobility control ability, avoid formation clogging problems, Effects with low long-term damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0036] This example provides oil displacement compositions prepared from different anionic amphiphilic polymers, and the anionic amphiphilic polymer has the following structure:

[0037]

[0038] As shown in the above structure, its hydrophobic group is n-hexadecyl, the content of hydrophobic monomer is 1.0%, the degree of hydrolysis is 25%, and the relative molecular mass is 328×10 4 , x:y:z=74:1:25.

[0039] The preparation method of this anionic amphiphilic polymer is:

[0040] First, dissolve acrylamide, hexadecyl acrylamide, and sodium acrylate in the sodium lauryl sulfate micellar solution according to the above ratio, and place it in a three-neck round bottom flask with a monomer mass concentration of 20%. The flask is equipped with a rubber diaphragm with a mechanical stirrer. Continue to feed nitrogen into the flask for 2 hours to make the flask anaerobic, then slowly add potassium persulfate-sodium bisulfite initiator system, the initiator concentration is 0.2% ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com