Method for advanced treatment of mercury-containing wastewater

A technology for advanced treatment and wastewater, applied in water/sewage treatment, natural water treatment, chemical instruments and methods, etc., can solve problems such as poor treatment effect of mercury-containing wastewater and environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

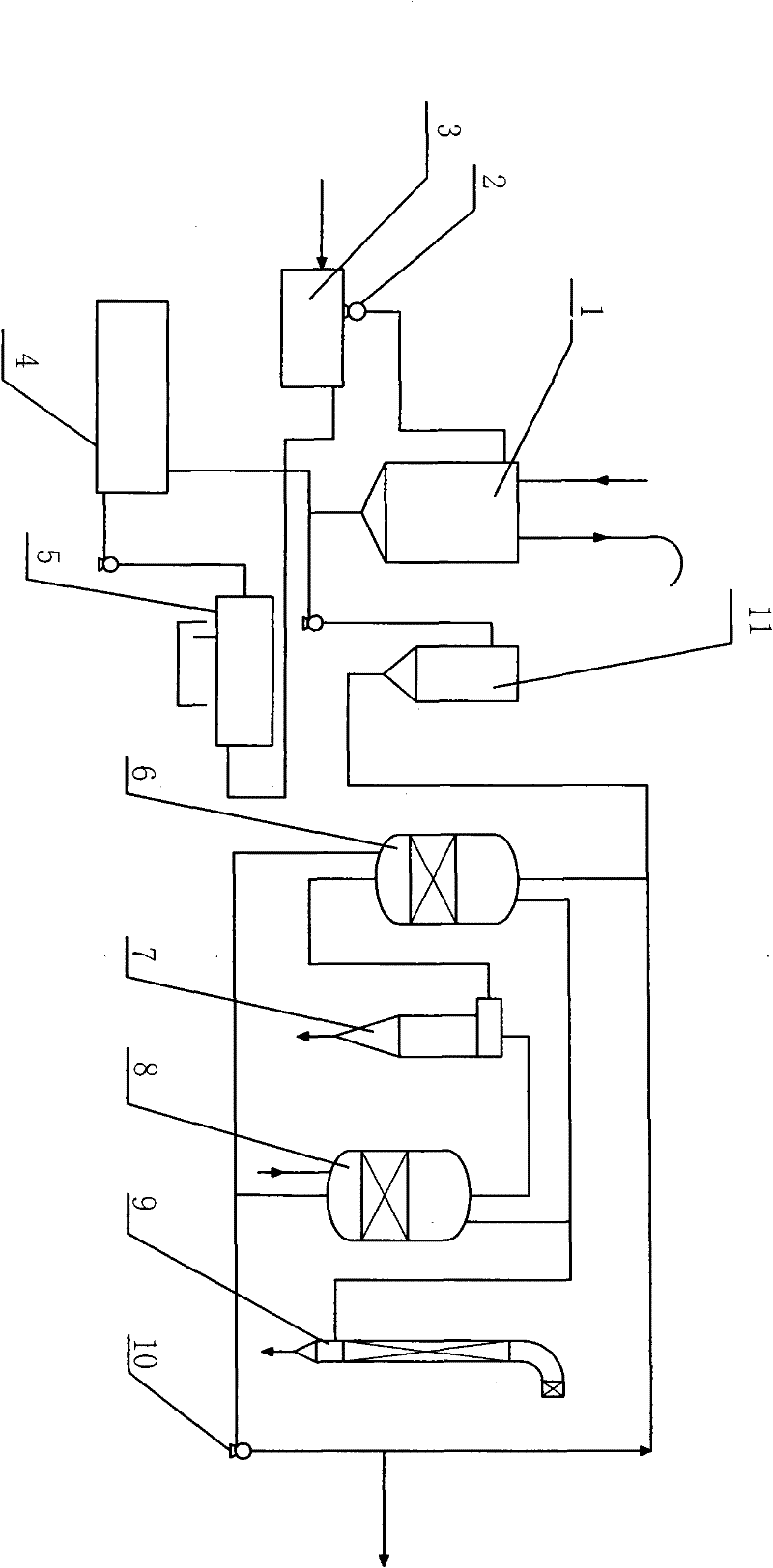

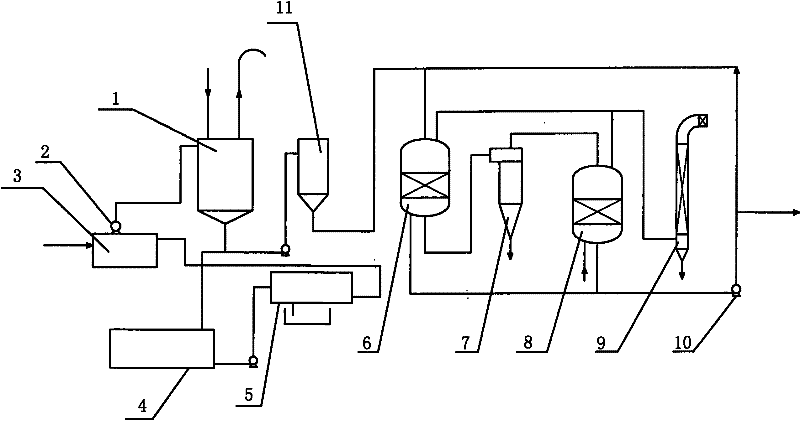

[0022] Refer to attached figure 1 Among them, the present embodiment includes the following steps: comprising a pH adjustment tank 3, a transfer pump 2, a reaction tank 1, a sludge thickening tank 4 and a solid-liquid separation device 5 for treating mercury-containing sludge connected in sequence, and the reaction tank is provided with a Sand filter tank 11 and advanced treatment device for mercury-containing wastewater, the steps are as follows: first, mercury-containing wastewater is collected into the pH adjustment tank, and the pH is adjusted to 9-11; Na 2 The S solution is fully reacted, and then the flocculant Fe is added 3+ , the generated HgS flocculent precipitates naturally settle down; the supernatant after the reaction is filtered through the sand filter tank and then enters the advanced treatment device for mercury-containing wastewater, and the precipitated HgS precipitate is removed to the sludge concentration tank and concentrated Then enter the solid-liquid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com